Overload protection type intelligent twisting and grinding machine

An overload protection, winch mill technology, applied in the direction of emergency protection circuit device, automatic disconnection emergency protection device, spring mechanism, etc., can solve the problems of inability to start, not considered, different transmission types, etc. With the effect of speed optimization, fast braking response, and improved ergonomics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

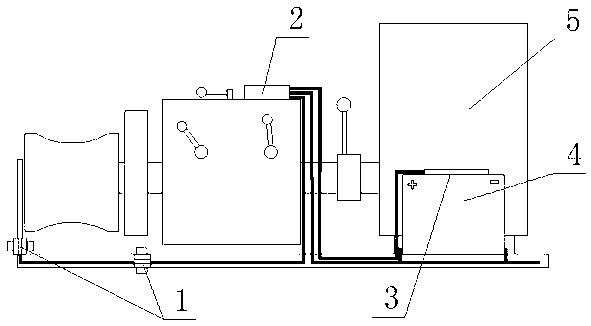

[0031] like figure 1 , 2 As shown in , 3, an overload protection type intelligent winch includes a tension sensor 1, a display and measurement part 2, a switch, a setting control part 3, an equipment power supply part 4 and an electric starter motor body 5, the tension sensor 1 and the The main body of the electric starter motor is hinged, the tension sensor 1 is electrically connected with the display measuring part 2, the display measuring part 2 is electrically connected with the switch and the setting control part 3, the display measuring part 2 is electrically connected with the equipment power supply part 4, and the display measuring part is electrically connected 2. It is electrically connected to the main body 5 of the electric starter motorized winch, and the equipment power supply component 4 is electrically connected to the body 5 of the electric starter motorized winch. The equipment power supply part of the overload-protected intelligent winching mill supplies p...

Embodiment 2

[0036] The difference between this embodiment and Embodiment 1 is that in this embodiment, the tension sensor component uses a strain gauge type tension sensor. The strain gauge type tension sensor has the advantages of high precision, wide measurement range, long life, simple structure, good frequency response characteristics, can work under harsh conditions, and is easy to achieve miniaturization, integration and variety diversification. Pull force measurement.

[0037] At the same time, in this embodiment, the display and measurement components of the overload-protected intelligent grinder are composed of a single-chip microcomputer and a liquid crystal screen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com