Propeller strut device of floating crane

A floating crane and herringbone technology, applied in cranes and other directions, can solve problems such as the inability of the herringbone to meet the navigable conditions of bridges, the inability to meet the requirements of bridge navigable height limits, and the reduction of the navigable height of the whole machine, so as to avoid capital and The effect of labor cost, simple and practical structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

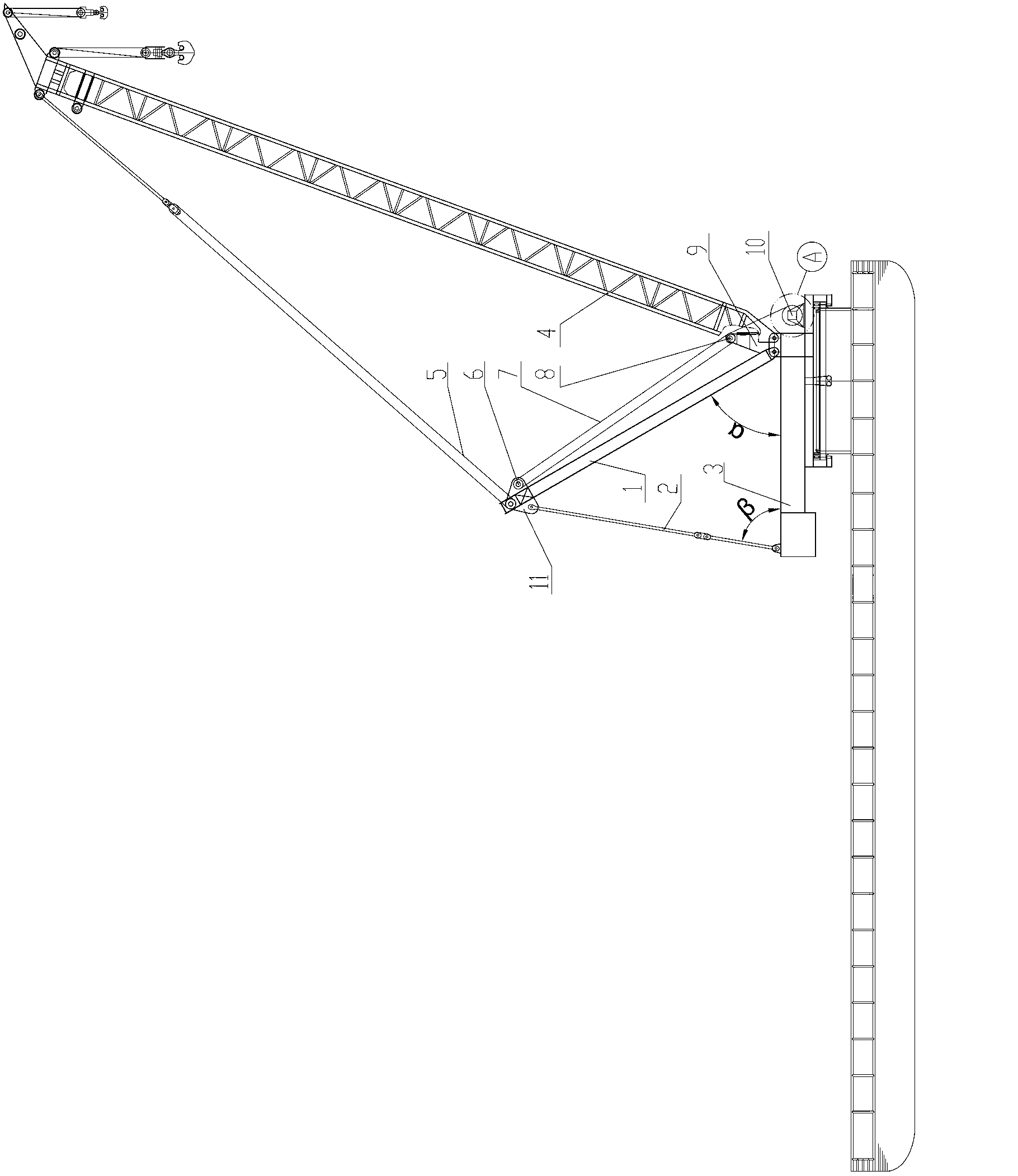

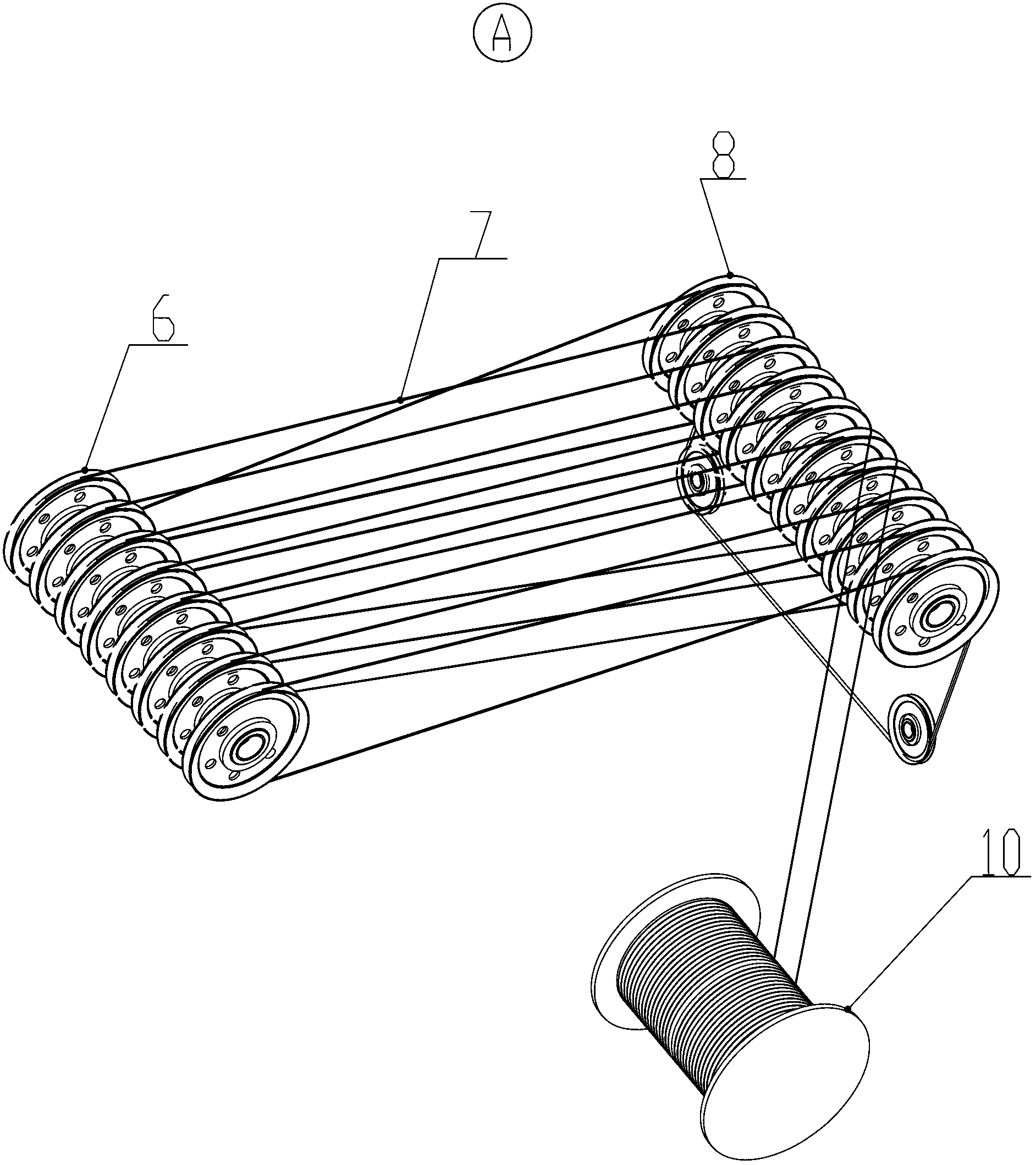

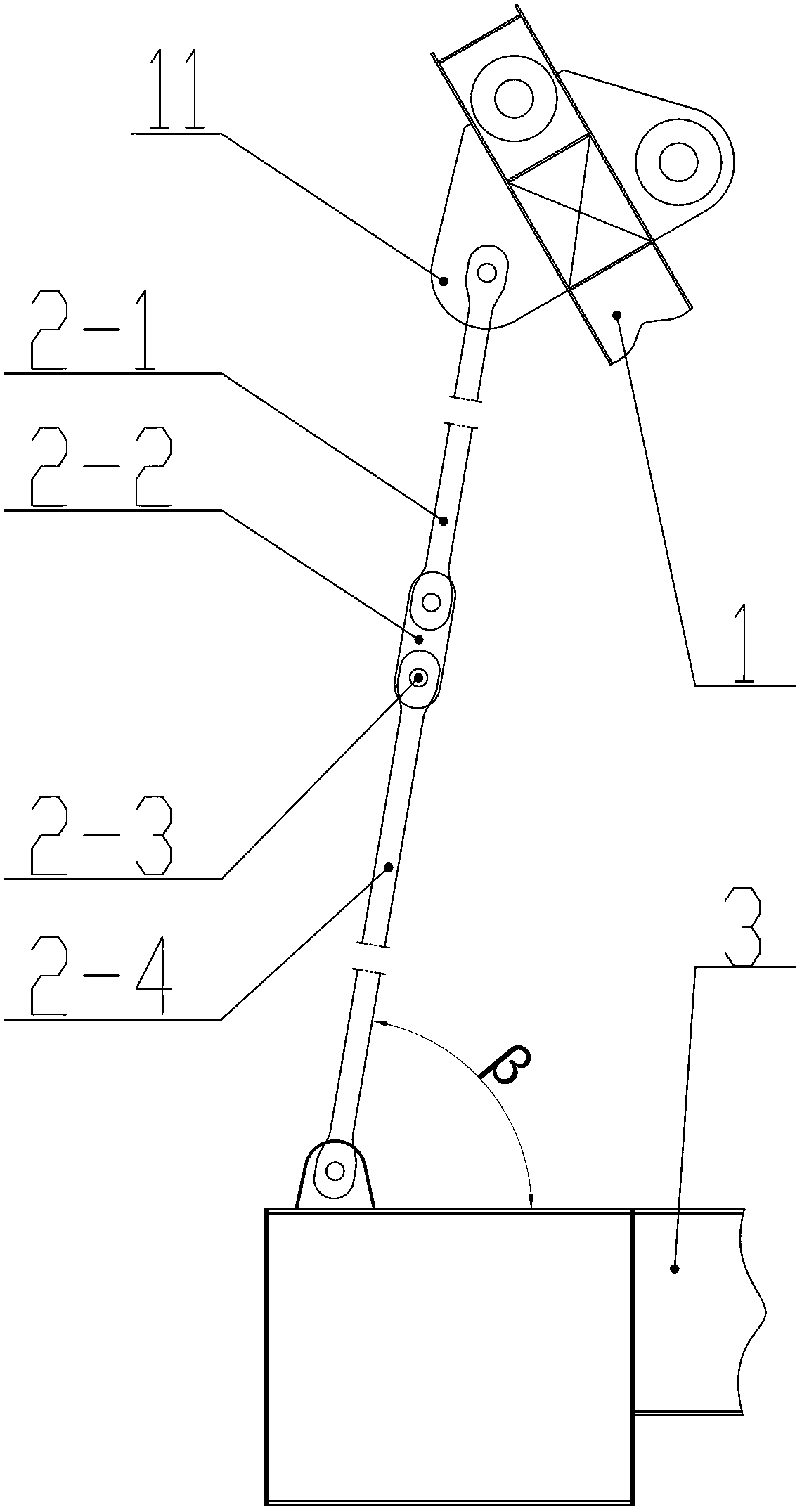

[0021] figure 1 Shown specific embodiment of the present invention, it is according to the large-scale floating crane crane that needs " its navigable state deck upper limit is high 14m requirement " according to the design, the herringbone device of the floating crane installed; Its structure comprises front strut 1. The foldable rear tie rod 2 and the turntable 3 are characterized in that: the herringbone frame adopts a folding type herringbone frame, and the foldable type herringbone frame is hinged at one end of the turntable 3 and the bottom end of the foldable rear tie rod 2 , the foldable rear tie rod 2 is composed of a first pull plate 2-1, a connecting frame 2-2, a pin shaft 2-3 and a second pull plate 2-4, and the top of the foldable rear pull rod 2 is hinged on the connecting plate 11, the angle between the foldable rear pull rod 2 and the turntable 3 is β angle; the other end of the turntable 3 is equipped with a support 9, a movable pulley block 6, a steel wire r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com