Cast iron ring carrier used for aluminum piston and manufacturing method thereof

A technology for inserting rings and cast iron, which is applied in the direction of pistons, manufacturing tools, and cylindrical pistons, etc. It can solve the problems of deformation, falling off of inserting rings, and affecting the bonding force between inserting rings and aluminum piston bodies, so as to reduce deformation, reduce weight, and improve Effect of High Temperature Volume Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

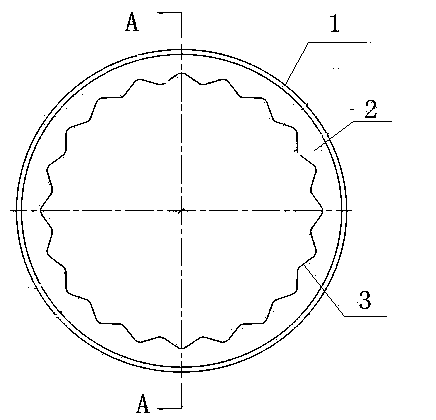

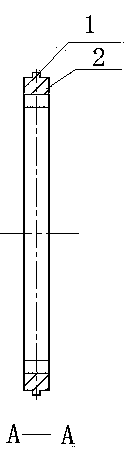

[0025] For the structure of the cast iron insert ring for the aluminum piston, please refer to the attached figure 1 And attached figure 2 , the ring structure for aluminum pistons in this embodiment includes a ring-shaped body 2, and a protruding ring-shaped support platform 1 is provided at the middle part of the outer circle of the ring-shaped body 2, and the support platform 1 It is integrally cast with the ring-shaped body 2 . The inner circle of the ring-shaped body 2 is uniformly distributed internal teeth 3. In this embodiment, the end faces of the internal teeth 3 are triangular in shape, and each corner of the triangle is excessively rounded and relatively gentle. The insert ring in this embodiment is suitable for aluminum pistons whose diameter is less than 100mm.

[0026] The material of the cast iron insert ring of the present embodiment selects the content of suitable carbon, silicon, manganese, phosphorus, sulfur, chromium, copper, and the specific weight per...

Embodiment 2

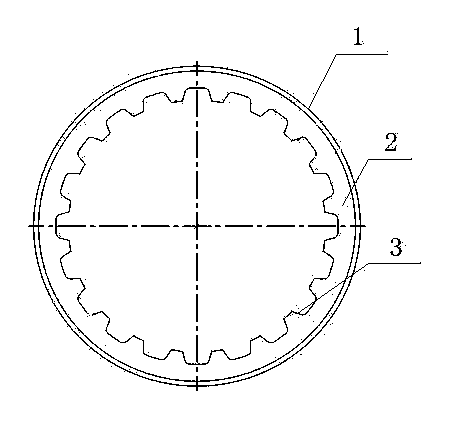

[0038] The structure of the setting ring in embodiment 2 is basically the same as that in embodiment 1, except that the shape of the inner teeth 3 is different. See attached image 3 , The shape of the internal teeth in Example 2 is an isosceles trapezoid, and the transition between every two adjacent sides of the isosceles trapezoid is also rounded. The ring with this structure is suitable for aluminum pistons with a piston diameter of 100-130mm.

[0039] The weight percentage of the material of the cast iron insert in this embodiment is shown in Table 1, the manufacturing method is the same as in Example 1; the mechanical properties are shown in Table 2, and other properties or metallographic structure are the same as in Example 1.

Embodiment 3

[0041] The structure of the insert in this embodiment differs from that of Embodiment 1 in that the shape of the inner teeth 3 is different. See attached Figure 4 In this embodiment, the shape of the end face of the internal tooth 3 is a rectangle, and the transition between every two adjacent sides of the rectangle is rounded. The ring with this structure is suitable for aluminum pistons with a piston diameter of 130-150mm.

[0042] The weight percentage of the material of the cast iron insert in this embodiment is shown in Table 1, the manufacturing method is the same as in Example 1; the mechanical properties are shown in Table 2, and other properties or metallographic structure are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com