A yarn winding apparatus and an operation original location adjusting method

A technology of coiling device and origin position, which is applied in the directions of transportation and packaging, conveying filamentous materials, thin material processing, etc., and can solve the problems detected by photoelectric sensor, offset of the origin position of action part, and influence of coiling action, etc. , to achieve the effect of suppressing the increase in power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

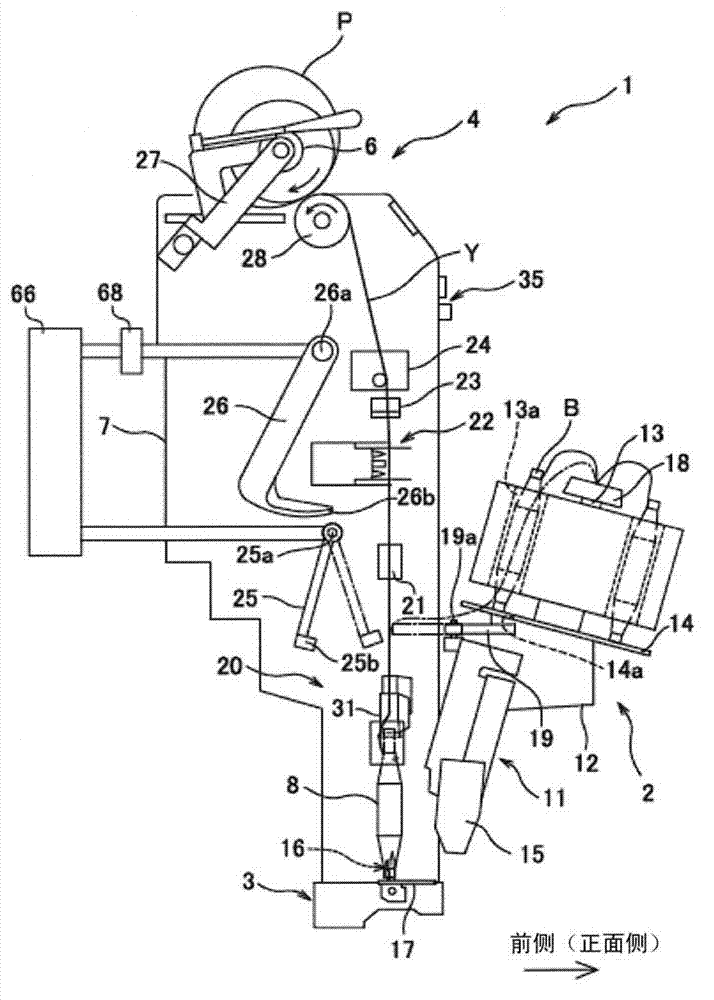

[0041] Next, embodiments of the present invention will be described. This embodiment is applied to an automatic winder including a plurality of winding units (yarn winding devices) that wind the yarn unwound from the yarn supply bobbin onto the winding bobbin to form a winding package. An example of invention. The automatic winder has a structure in which winding units forming one package are arranged in multiple rows in one direction. figure 1 It is a side view of one winding unit of the automatic winder. In addition, in figure 1 In , the right side is defined as the front side (front side) where the operator works on the winding unit 1 , and the left side is defined as the opposite rear side (back side).

[0042] Such as figure 1 As shown, the winding unit 1 includes a bobbin supply device 2, a bobbin support portion 3, and a yarn winding portion 4, respectively. In addition, the operation of the winding unit 1 is controlled by the control device 50 . Further, the wind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com