Monofilament tension control mechanism

A tension control mechanism and monofilament technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems that monofilaments cannot automatically realize real-time tension adjustment, so as to improve reliability and stability, Avoid the use of electrical components and ensure the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

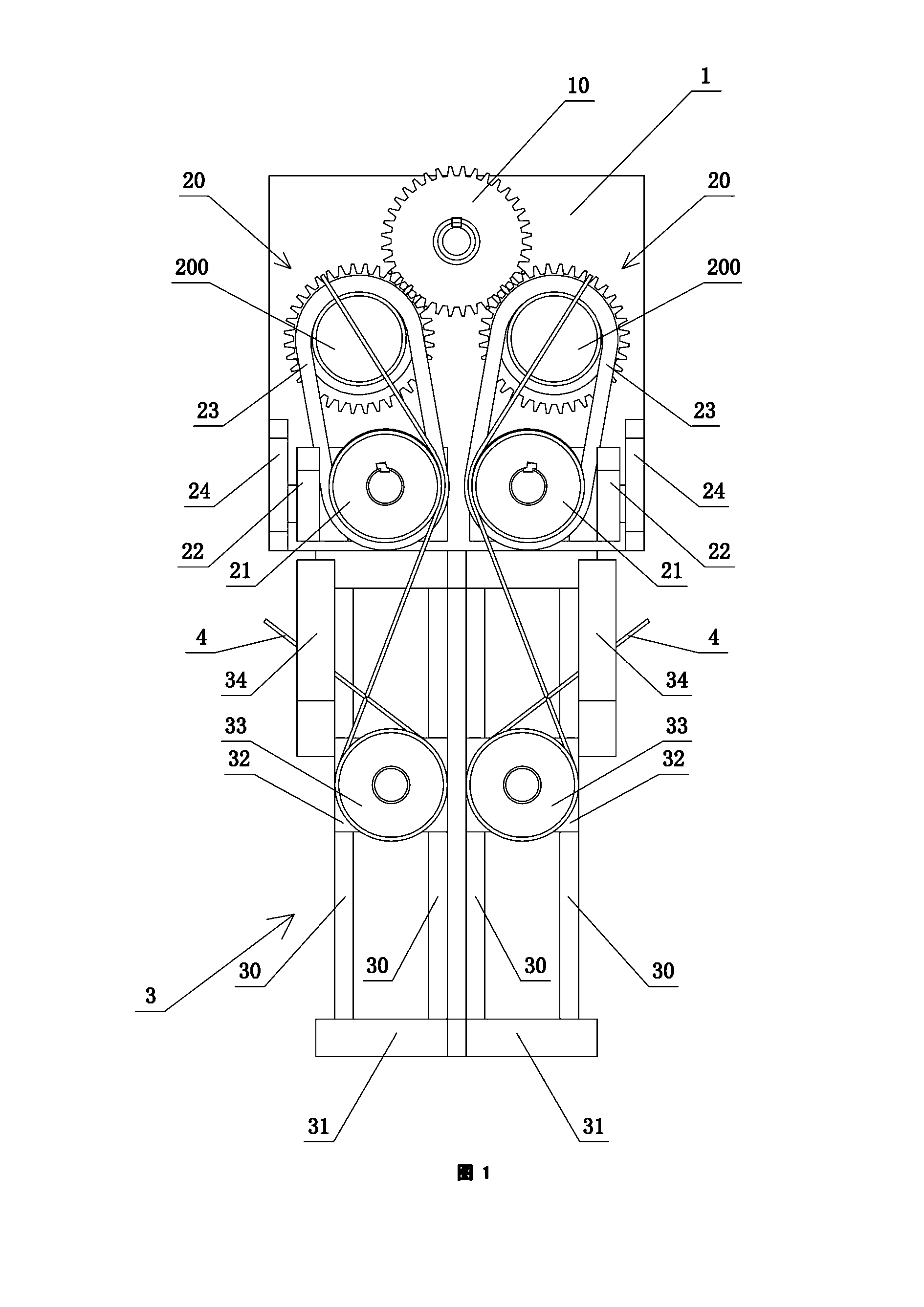

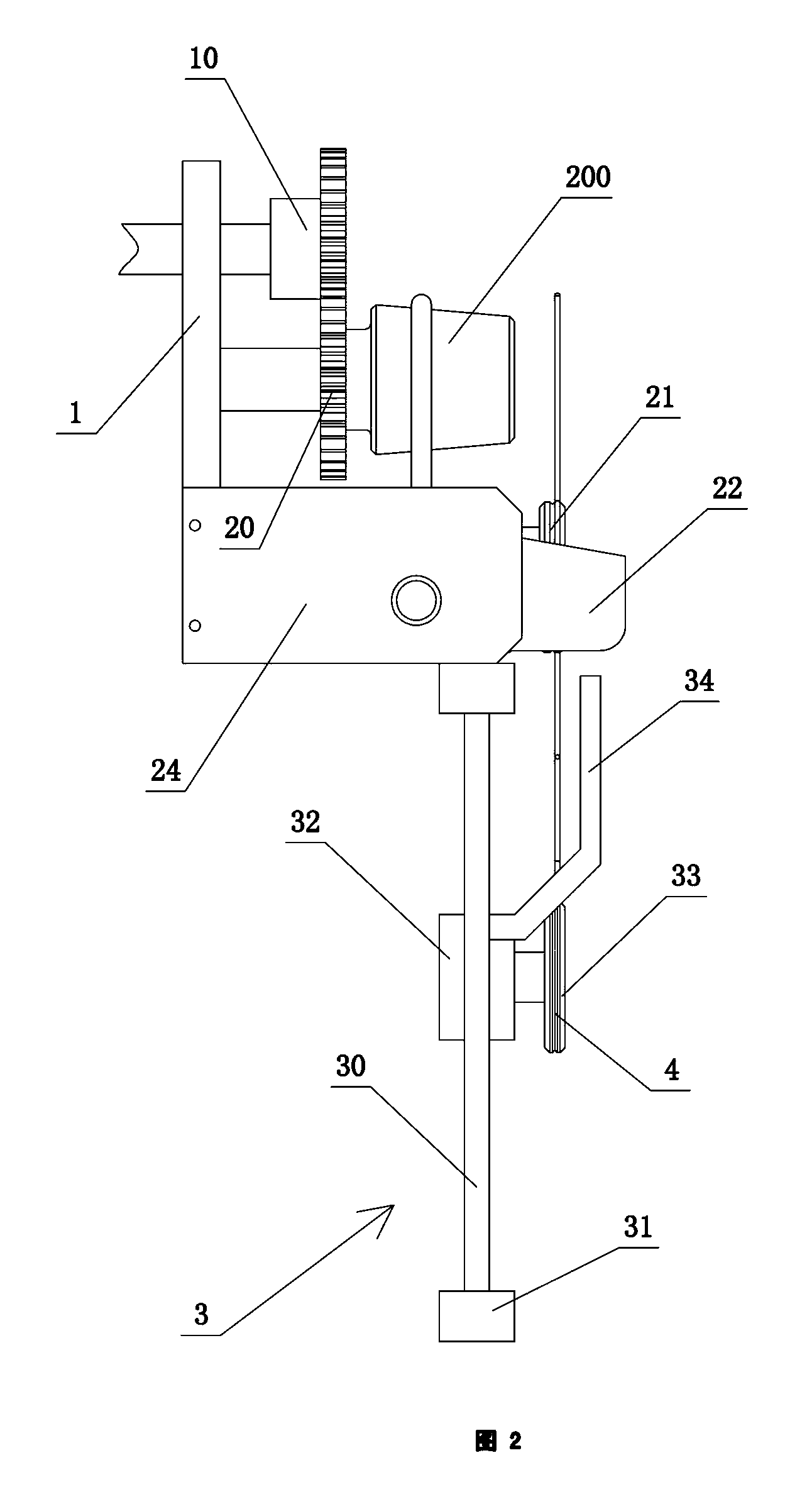

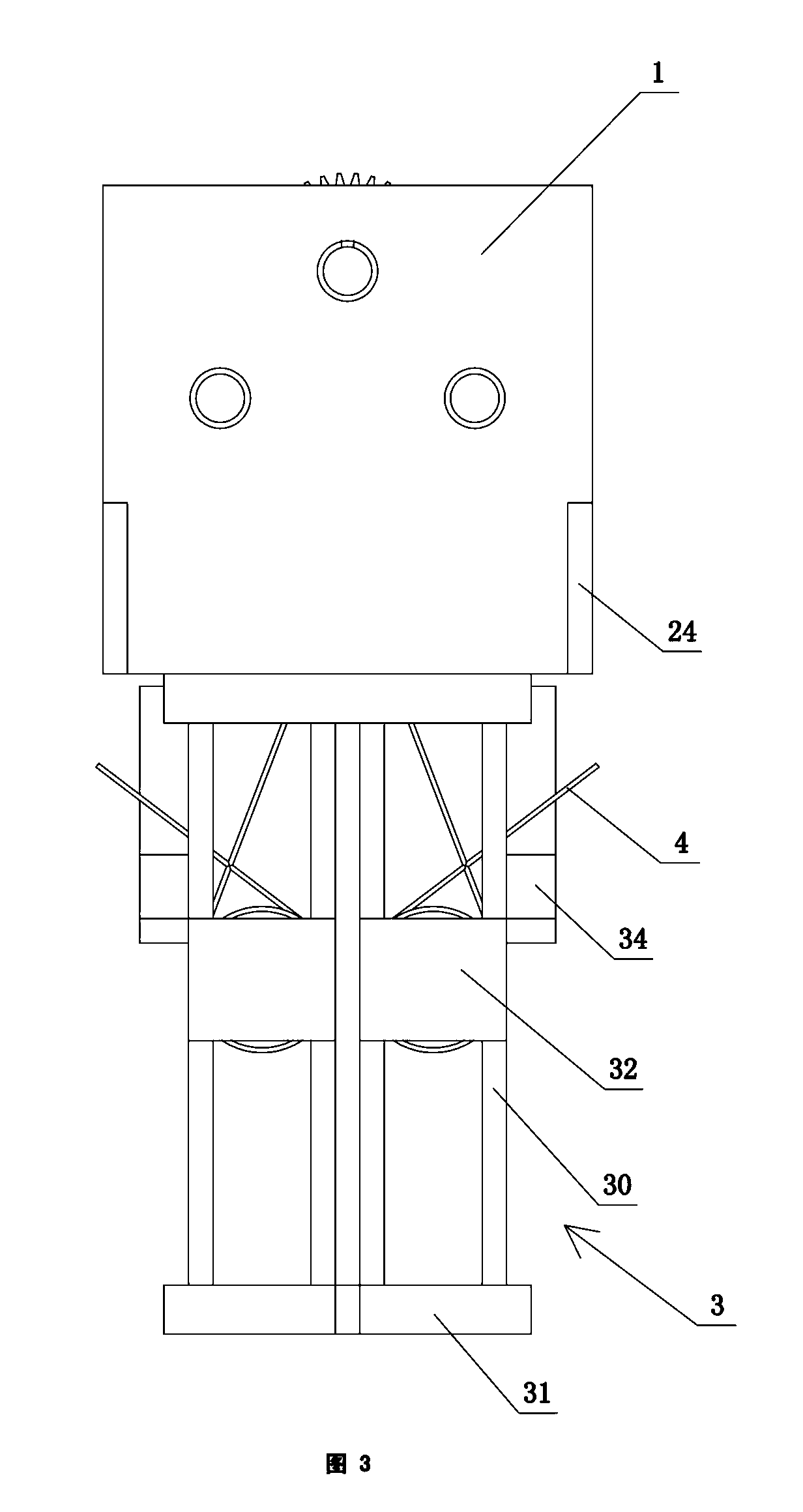

[0022] Refer to attached figure 1 , figure 2 and image 3 . A monofilament tension control mechanism includes a main base 1 , an automatic adjustment assembly installed on the main base 1 , and a comb chain device 3 matched with the automatic adjustment assembly. The main base 1 is equipped with a main transmission wheel 10 .

[0023] Refer to attached figure 1 , figure 2 , image 3 and Figure 6 . The automatic adjustment assembly is divided into two groups, and each group of automatic adjustment assembly includes a driven inclined wheel 20, a swing wheel 21, an L-shaped swing arm 22, an adjustment belt 23 and fixedly connected to the main assembly. The base plate 10 corresponds to a balance wheel support plate 24 on the side wall. The driven inclined wheel 20 is engaged with the main transmission wheel 10, and its front part is a conical rotating part 200 for driving the adjustment belt 23 to rotate. The swing wheel 21 is connected to one end of the swing arm 22 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com