Bunker with sealing device

A technology with sealing and mine trough, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of reducing accident rate, reducing infrastructure investment, etc., achieve good sealing and dustproof effect, eliminate infrastructure cost investment, and have a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

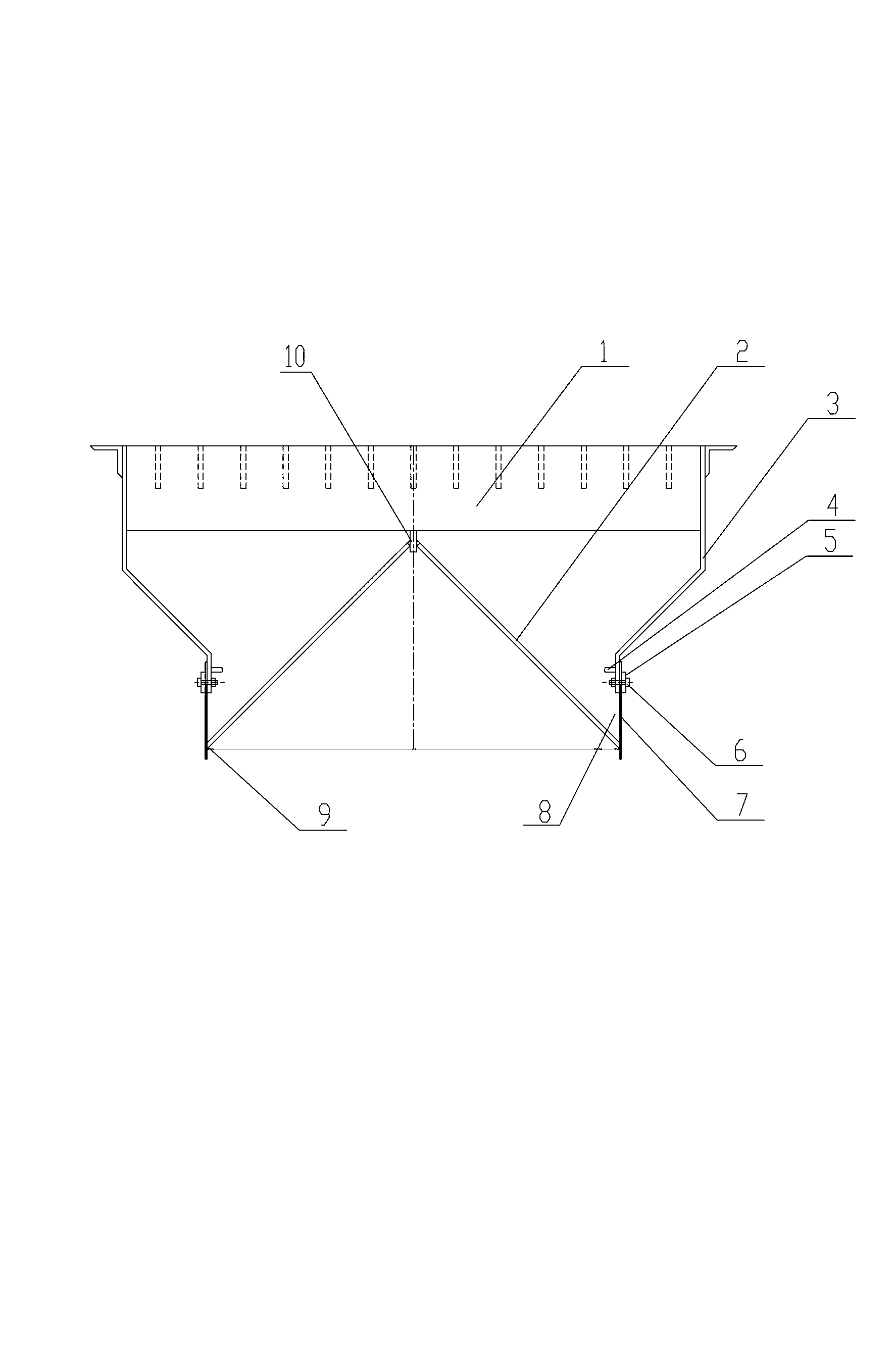

[0014] Such as figure 1 As shown, the mine tank with sealing device of the present invention includes a mine tank body 3, and a blanking grate plate 1 arranged on the top of the mine tank body 3 is characterized in that the blanking grate plate 1 is in the mine tank body 3 The lower part of the chute is inclined to be provided with a guide chute 2, one end of the guide chute 2 is connected with the lower end 10 of the middle part of the blanking grate plate 2, and the other end is connected with the bottom corner 9 of the mine trough 1, and the mine trough discharge port 8 is arranged in the mine trough 1 The lower part of the side wall is provided with a sealing rubber plate 7 at the discharge port 8 of the mine tank, one end of the sealing rubber plate 7 is connected to the side wall of the mine tank through bolts, nuts 6 and pressing pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com