Positioning support for micro drive motor

A micro-drive motor, positioning bracket technology, applied in electrical components, electromechanical devices and other directions, can solve the problems of low processing accuracy, can not be used for positioning, can not guarantee the bonding strength and other problems, to increase the impact resistance, improve the pass rate, Improves the effect of linear drive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (Embodiment 1, positioning bracket)

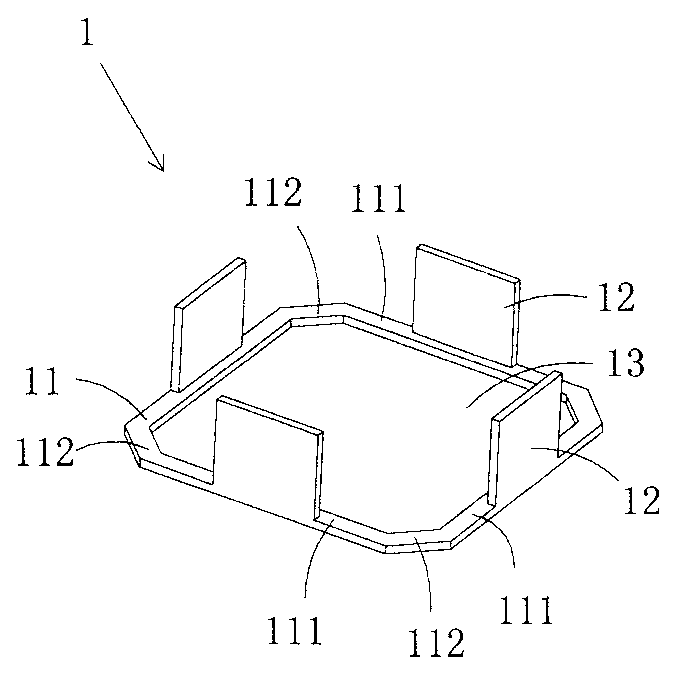

[0024] figure 1 It is a three-dimensional structural schematic diagram of the first structure of the positioning bracket of the present invention, showing the first specific embodiment of the positioning bracket of the present invention.

[0025] This embodiment is a positioning bracket for a micro drive motor, see figure 1 As shown, it includes a plate-shaped body 11 made of insulating plastic and four supporting bosses 12 protruding from the plate-shaped body for abutting on the outer ring of the upper spring leaf. The center of the plate-shaped body 11 A through hole (13) is provided, and each support boss 12 is located on the same side of the plate-shaped body.

[0026] The basic shape of the plate-like body 11 is a rectangular frame with four pressing edges 111. In this embodiment, the basic shape of each pressing edge 111 is a straight plate shape; at the center.

[0027] In practice, the number of the supporting bosses 12...

Embodiment 2

[0028] (Embodiment 2, positioning bracket)

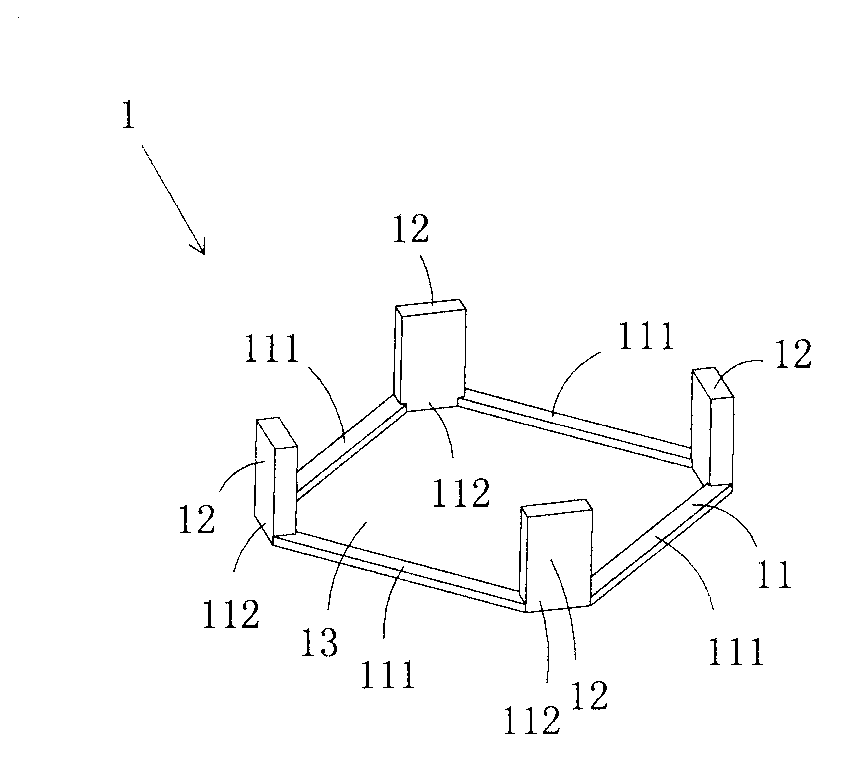

[0029] figure 2 It is a three-dimensional structural schematic diagram of the second structure of the positioning bracket of the present invention, showing the second specific embodiment of the positioning bracket of the present invention.

[0030] This embodiment is basically the same as Embodiment 1, the difference is: see figure 2 As shown, each supporting boss (12) is located at the junction of two adjacent pressing edges (111).

Embodiment 3

[0031] (Embodiment 3, positioning bracket)

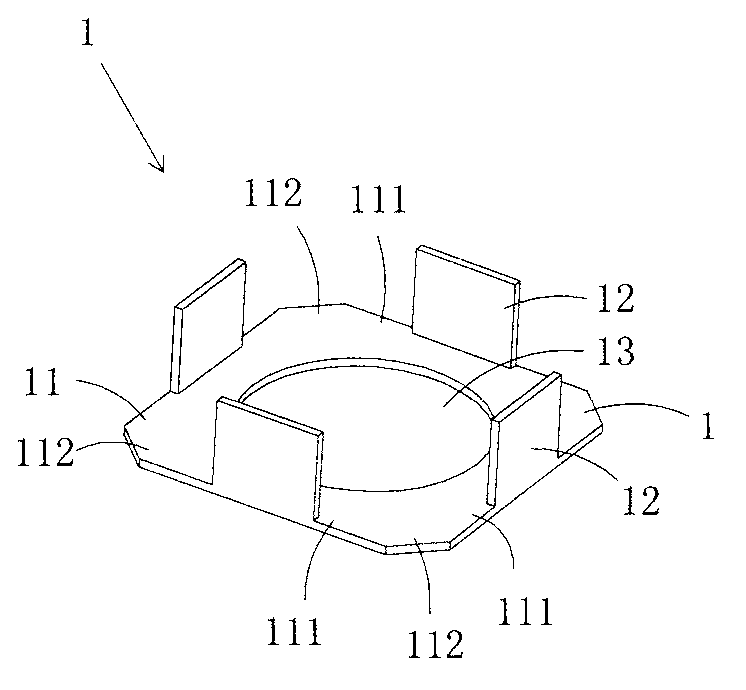

[0032] image 3 It is a three-dimensional structural schematic diagram of the third structure of the positioning bracket of the present invention, showing the third specific embodiment of the positioning bracket of the present invention.

[0033] This embodiment is basically the same as Embodiment 1, the difference is: see image 3 As shown, the basic shape of each blank 111 and the plate-shaped body 11 formed by their combination is different from that of Embodiment 1. In this embodiment, the inner edge of each blank 111 is arc-shaped, and all blanks 111 are enclosed to form A circular hole; the shape of the through hole 13 in Embodiment 1 is close to a rectangle.

[0034] In practice, the shape of the through hole 13 can be various, it can be regular shape or irregular shape, it only needs to be able to crimp and fix the outer edge of the circumscribed lower shrapnel without hindering the circumscribed The wire spring of the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com