Air vent structure of sealing relay and air vent sealing method thereof

A technology of air vents and relays, applied in relays, relay ventilation/cooling/heating, electrical components, etc., can solve the problems of degumming, easy sticking of dispensing needles, high power consumption, etc., and achieve low power, reliable bonding, and heating small position effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

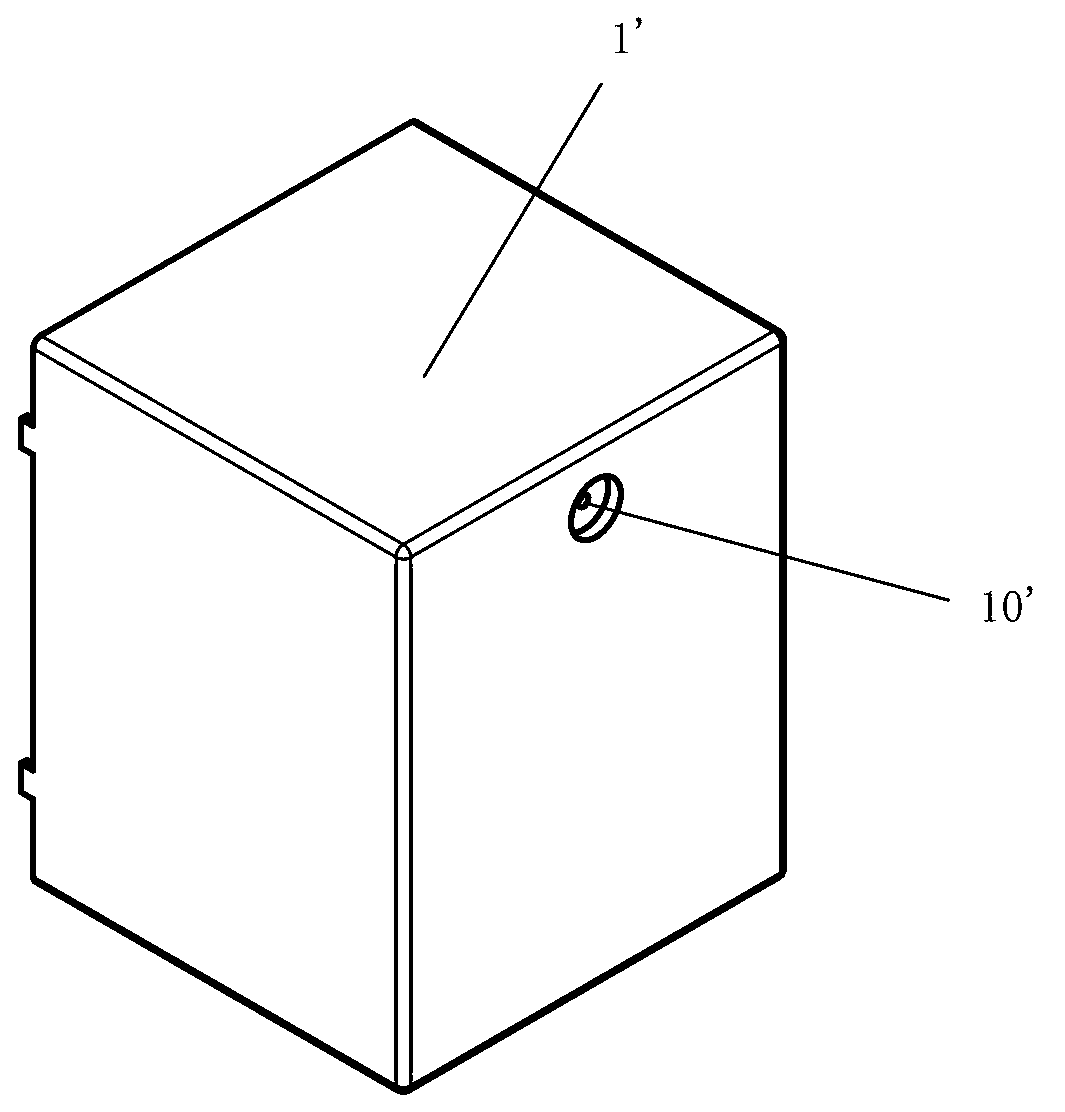

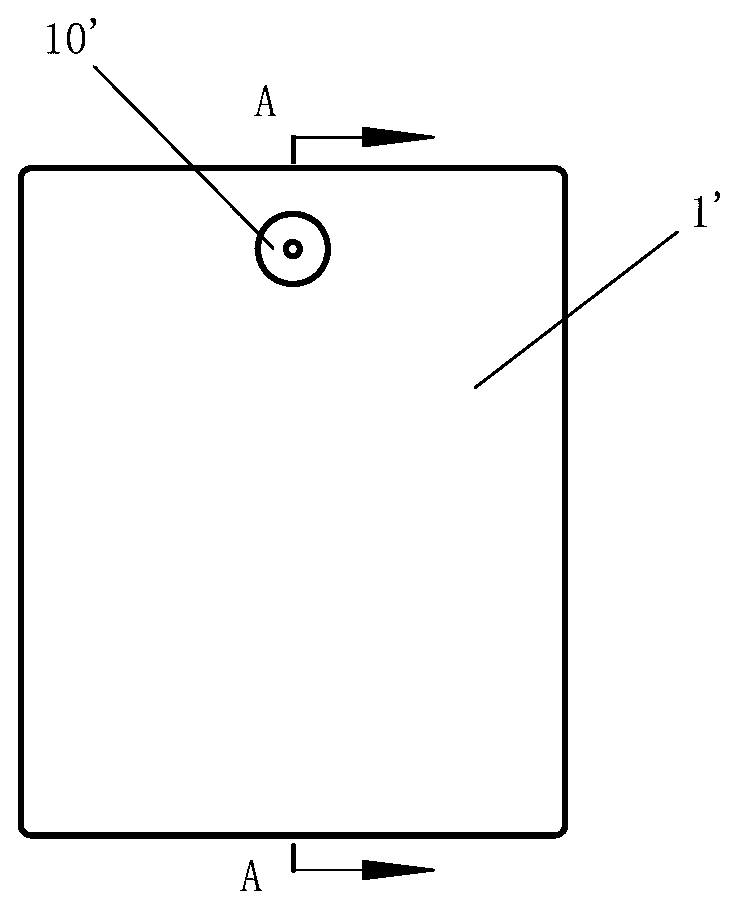

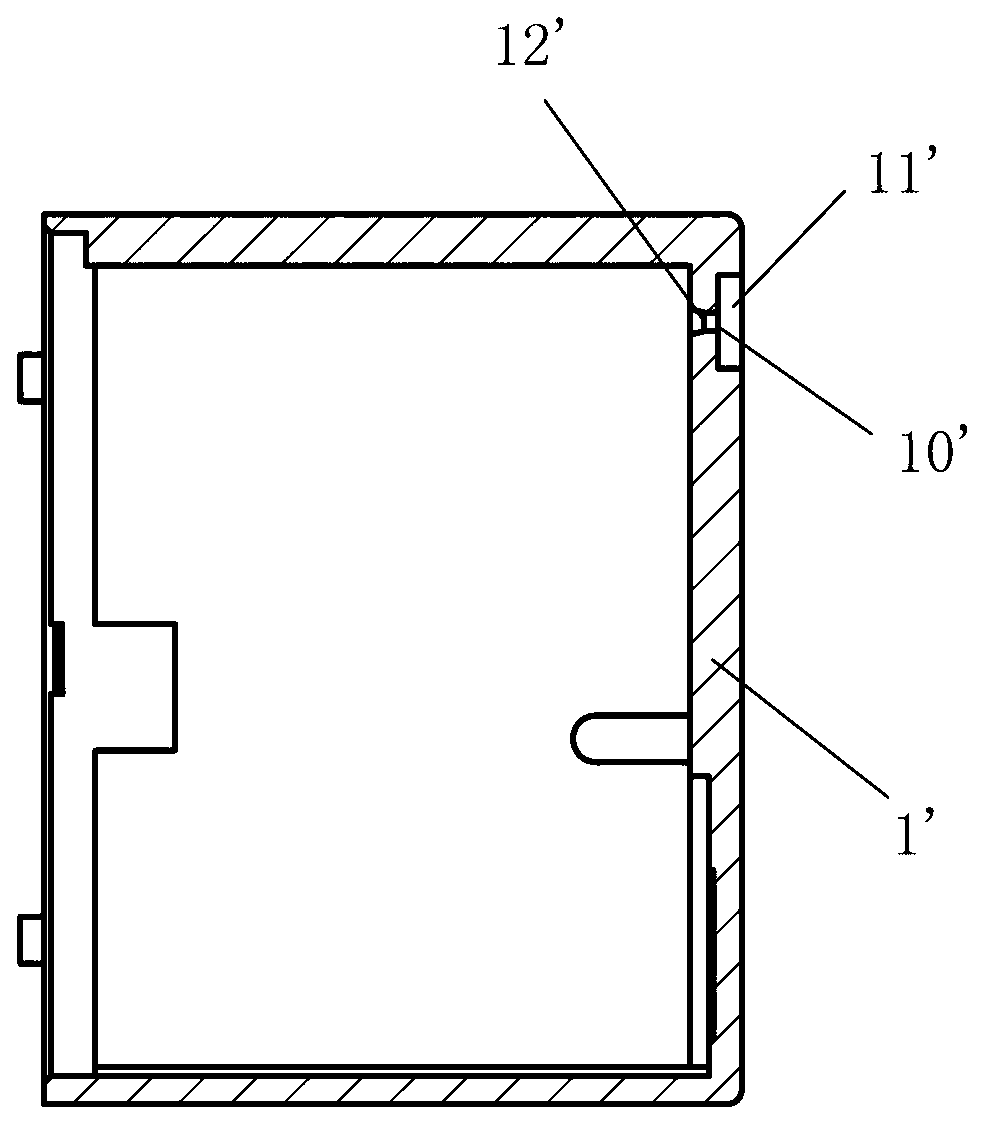

[0037] Examples, see Figure 5 to Figure 7 As shown, the ventilation hole structure of a sealed relay of the present invention includes a housing 1, and the outer surface of the housing 1 is provided with an inwardly concave sinking portion 11, and in the sinking portion 11, an outwardly protruding Protruding post 12, and the height dimension of the protruding post 12 is consistent with the depth dimension of the sinking part 11, and a vent hole 13 is provided in the middle of the protruding post 12 to allow the air inside and outside the housing to communicate.

[0038] The cross-sectional shape of the boss 12 is circular.

[0039] Certainly, the cross-sectional shape of the protruding column may also be oval; or triangular, square, or polygonal.

[0040] see Figure 5 to Figure 10 As shown, a method for sealing air holes of a sealed relay of the present invention comprises the following steps:

[0041] (1) On the outer surface of the housing 1, an inwardly concave sunken ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com