Mechanical interlocking type parking brake for railway vehicle

A technology for parking brakes and railway vehicles, applied in mechanical equipment, brake actuators, gear shifting mechanisms, etc., can solve problems such as unfavorable layout, high operator dependence, wheel tread scratches, etc., to avoid wheel tread scratches , The effect of optimizing the overall structure and reducing the space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

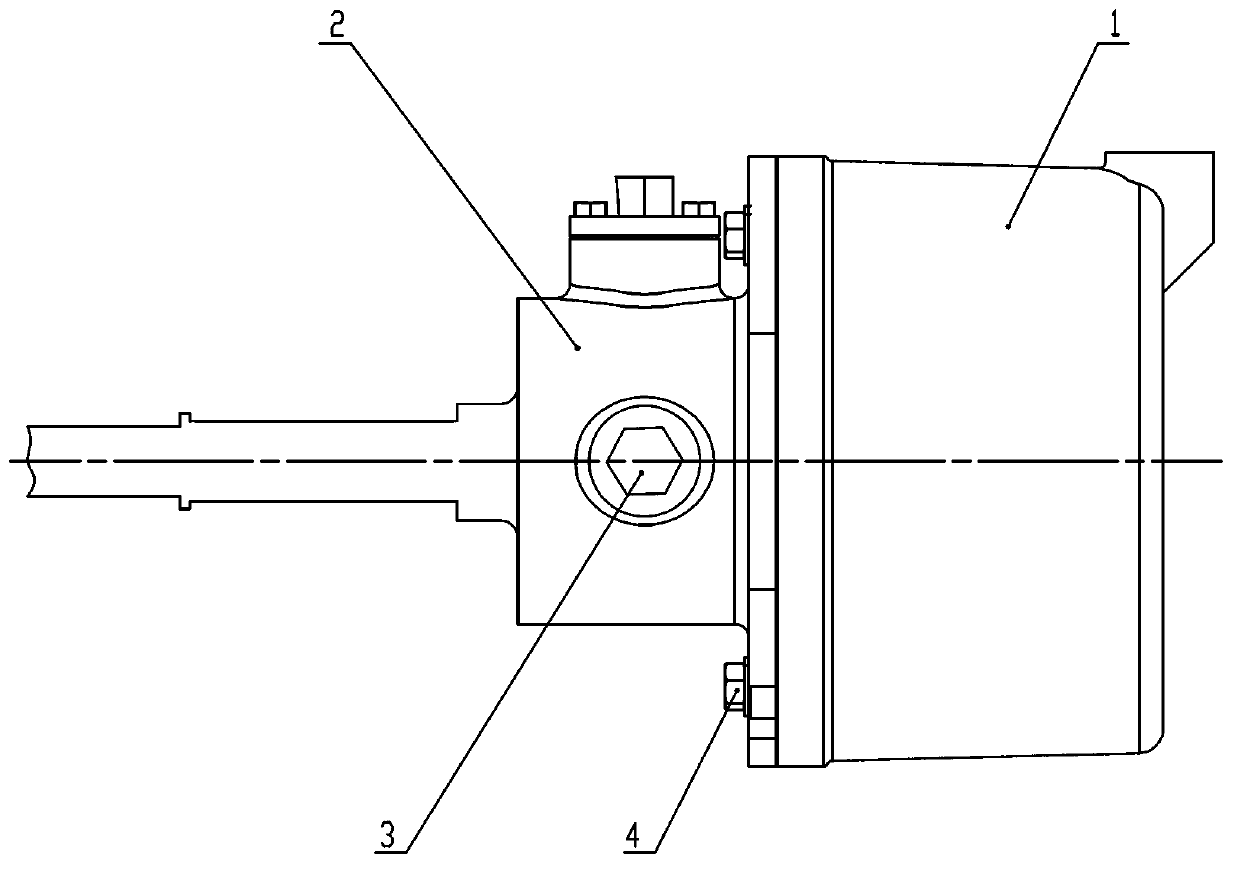

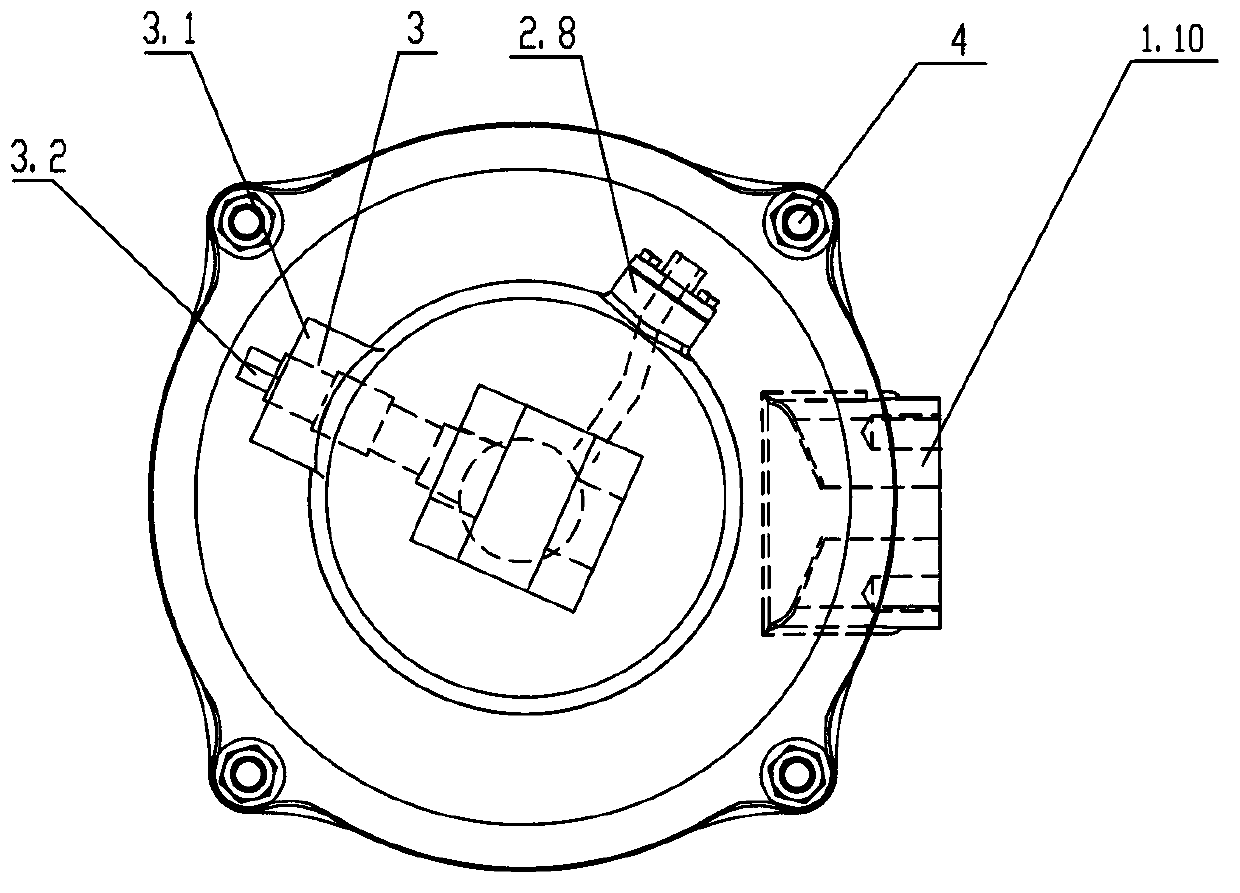

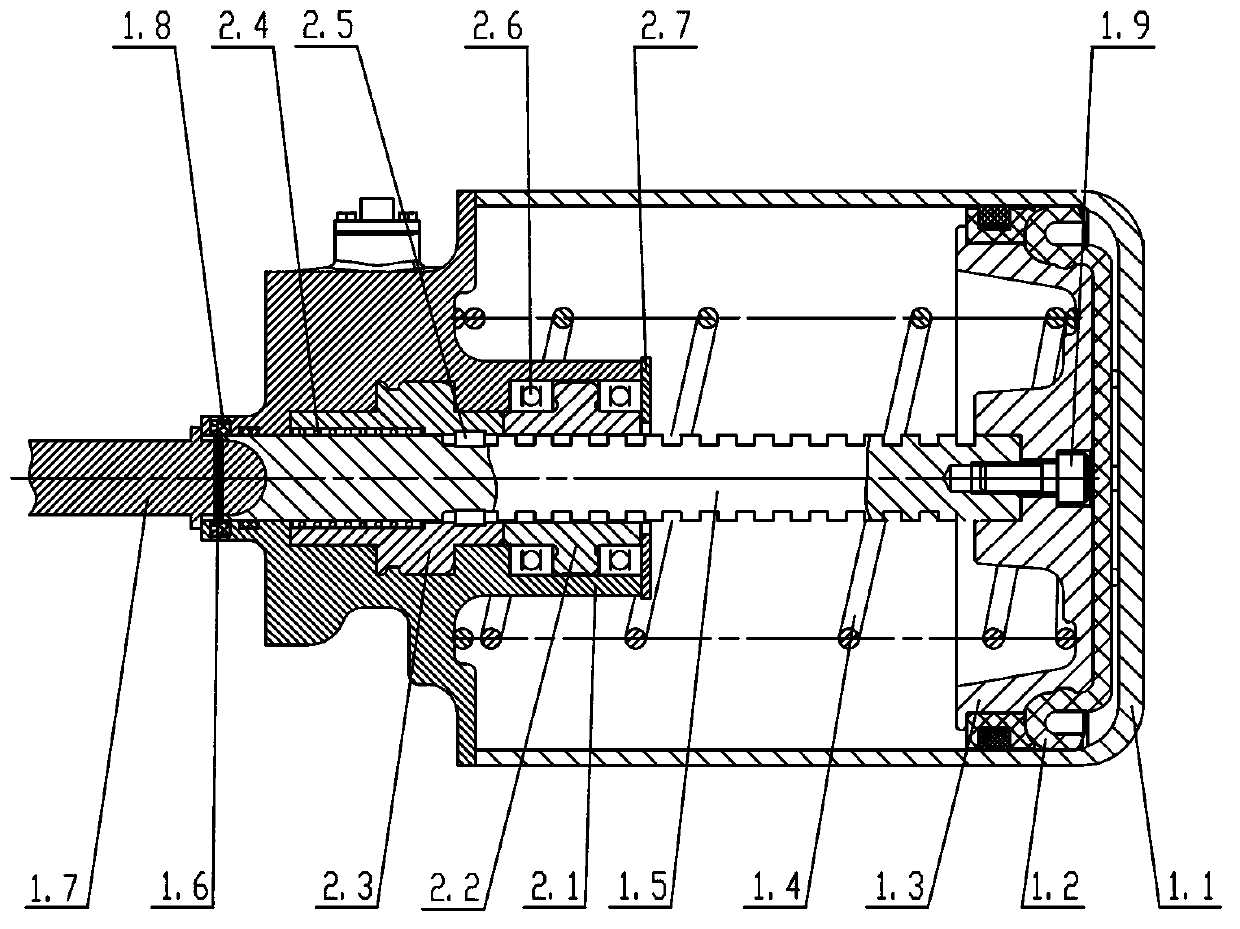

[0036] The mechanical locking parking brake for railway vehicles shown in the figure is mainly composed of a brake cylinder component 1 and a mechanical locking mechanism 2, which are connected as a whole by a bolt component 4.

[0037] The above-mentioned brake cylinder composition 1 has a cylinder body 1.1, a piston 1.3 is installed in the cylinder body 1.1, a diaphragm 1.2 is nested on the working end surface of the piston 1.3, the center of the skirt of the piston 1.3 is connected with one end of the piston rod 1.5 through a screw 1.9, and the piston A relief spring 1.4 is set on the rod 1.5, and the bottom of the cylinder body 1.1 is provided with an air inlet and outlet flange joint 1.10 connected with the vehicle brake pipeline.

[0038] The above-mentioned mechanical locking mechanism 2 has a locking seat 2.1 which doubles as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com