A vehicle-mounted mud pump unit device

A mud pump and unit technology, which is applied in the field of vehicle-mounted mud pump unit installation, can solve the problems of large space occupation, mud failure, broken frame, etc., and achieves the effect of solving large space occupation, easy arrangement and ensuring stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

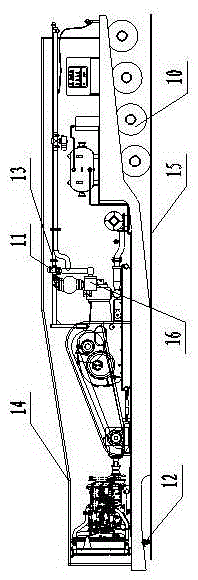

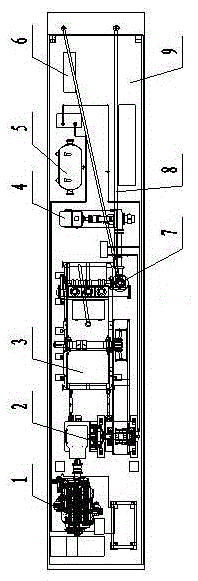

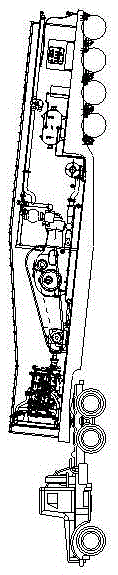

[0010] The structure and use of the present invention will be described in detail below in conjunction with the embodiments given in the accompanying drawings. Referring to the accompanying drawings, this vehicle-mounted mud pump unit device mainly includes a diesel engine, a clutch, a mud pump, a filling pump, an air compressor, and a control cabinet, and is characterized in that the diesel engine (1), the clutch (2), the mud pump (3) , the perfusion pump (4), the air compressor (5) and the control cabinet (6) are installed on the upper surface of the frame (9). The upper surface of the frame is basically a step-shaped surface composed of two plane transition connections. The lower surface is a structure with a front sloped surface and a middle flat surface in contact with the ground, which is connected to a larger sloped surface of a wheel set on which the axle is installed via one end sloped surface and a transition surface. There is a traction shaft (12) below.

[0011] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com