An environmentally friendly and energy-saving hydraulically driven pile driver

An energy-saving and driving technology, applied in sheet pile walls, buildings, infrastructure engineering, etc., can solve the problems of easy leakage of ore-based hydraulic oil, consumption of large oil resources, high operating costs, etc., and achieve good environmental benefits and low operating costs Low, easy to move effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

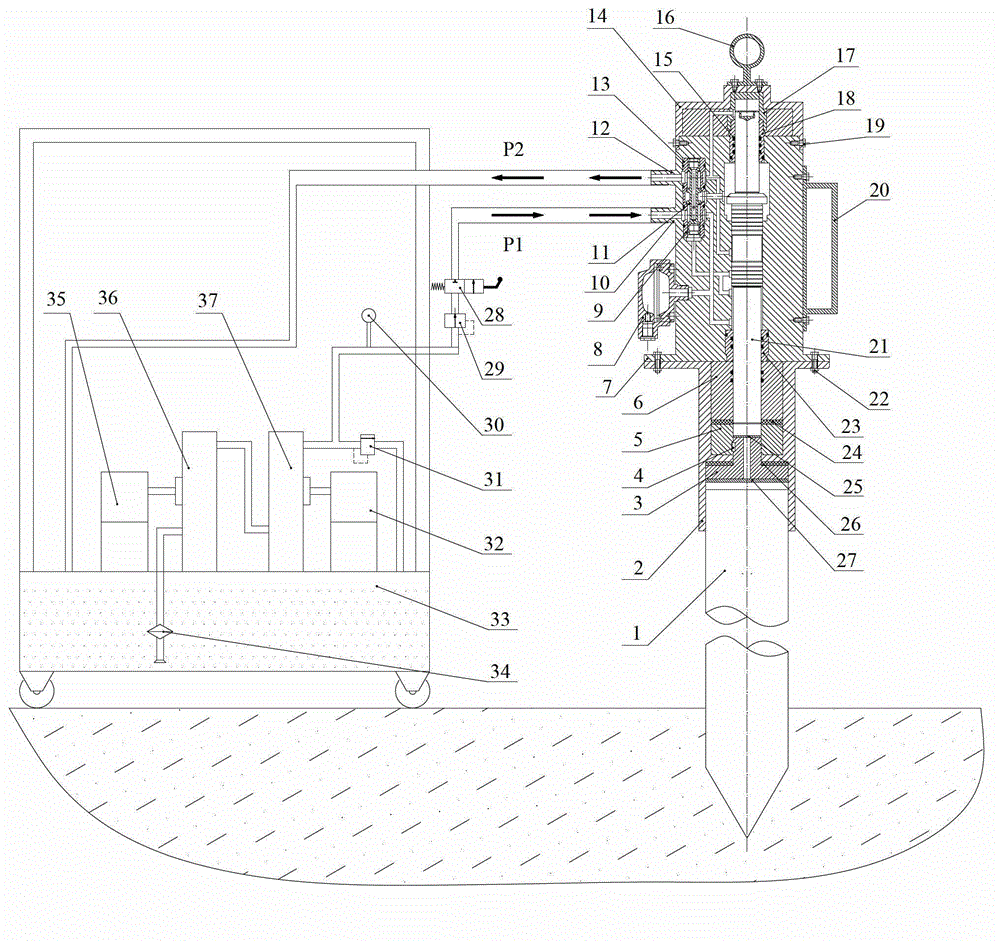

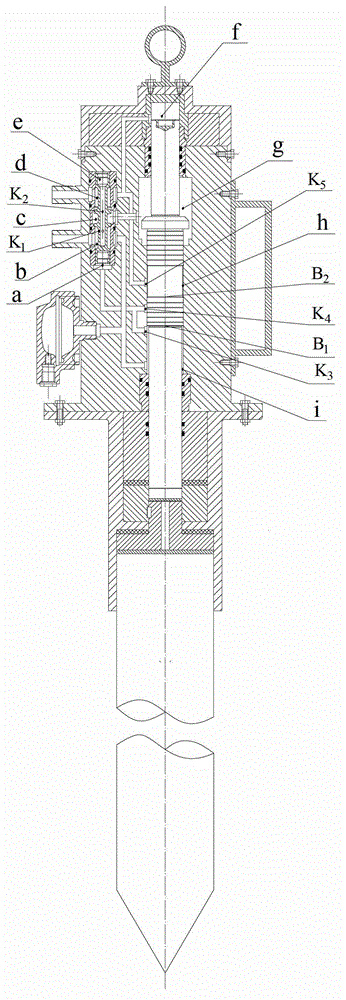

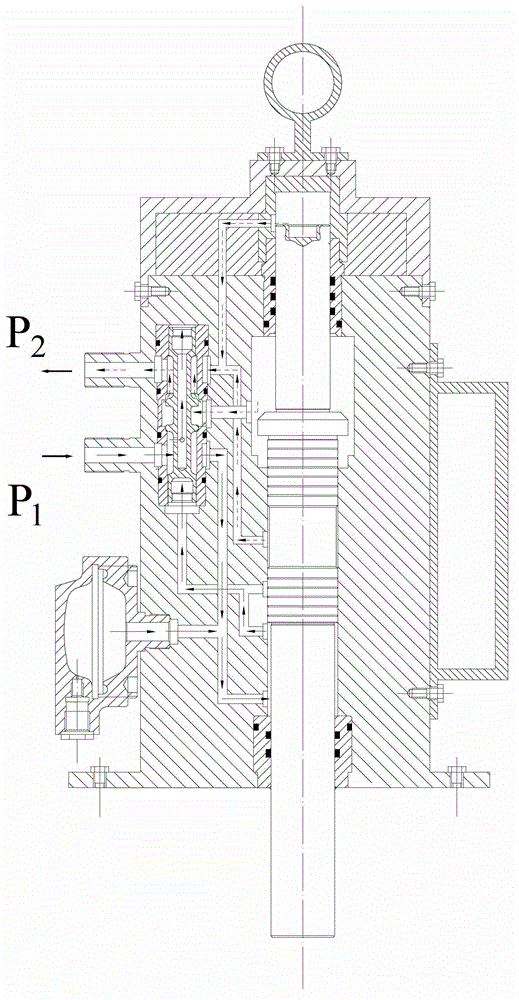

[0019] Such as figure 1 As shown, the present invention includes a power mechanism, an impact mechanism and a piling joint mechanism, and the power mechanism includes a water tank 33, a first motor 35, a second motor 32, a centrifugal water pump 36, a booster water pump 37, an outlet pipe P1 and a return pipe P2 The water tank 33 communicates with the inlet of the centrifugal water pump 36 through a pipeline, and a filter 34 is arranged on the pipeline connecting the water tank 33 and the inlet of the centrifugal water pump 36 . The outlet of the centrifugal water pump 36 is connected with the inlet of the booster water pump 37; the centrifugal water pump 36 is connected with the first motor 35, and the booster water pump 37 is connected with the second motor 32; the outlet of the booster water pump 37 is connected with the outlet pipe P1 In communication, the outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com