Method for improving thermochromatic characteristic of vanadium dioxide film

A vanadium dioxide and thin film technology is applied in the field of preparing vanadium dioxide sculpture thin films on a substrate by using a vacuum oblique deposition technology, which can solve the problems of low visible light transmittance, unsatisfactory thermochromic performance and the like, and achieve improved thermochromic performance. , The effect of visible light transmittance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

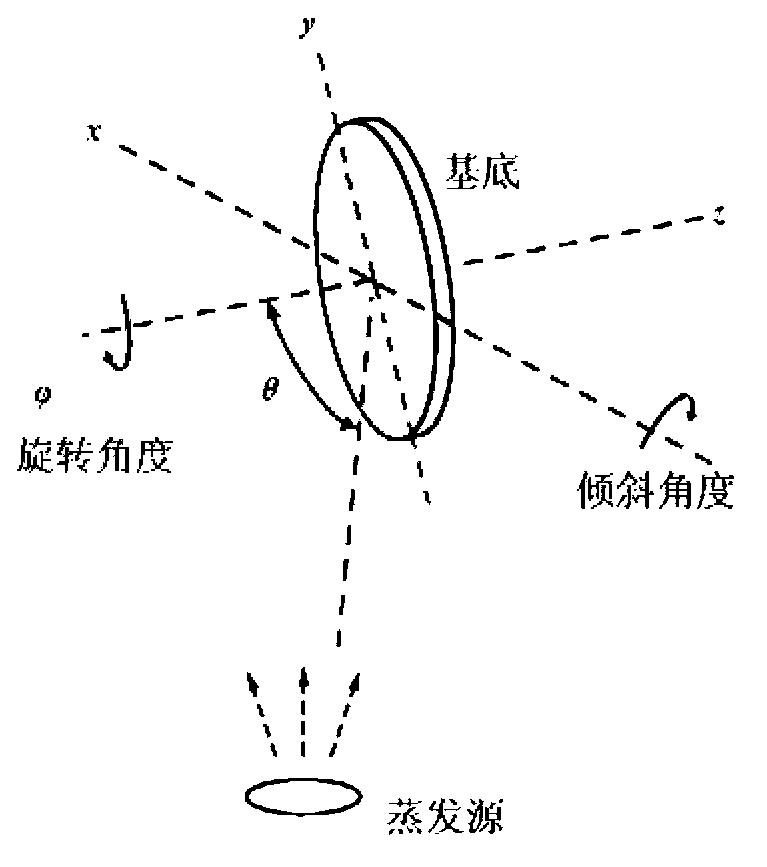

[0021] In the chamber of the electron beam evaporation equipment, adjust the angle between the substrate and the evaporation source to 20 degrees, use vanadium pentoxide particles as the film material, the substrate temperature is room temperature, and the oxygen partial pressure is 2*10 -3 At Pa, a vanadium dioxide film is deposited on a quartz substrate, and the deposited film is heat-treated at 600 degrees for 30 minutes in a hydrogen / argon mixed atmosphere to obtain an oblique columnar vanadium dioxide film.

Embodiment 2

[0023] In the chamber of the laser pulse deposition equipment, the angle between the substrate and the evaporation source is adjusted to 0 degrees while the substrate rotation speed is 256 revolutions per minute, vanadium tetroxide particles are used as the film material, the substrate temperature is room temperature, and the oxygen partial pressure is 2.5*10 -3 At Pa, a vanadium dioxide film is deposited on a borosilicate glass substrate, and the deposited film is heat-treated at 500 degrees for 1 hour in an argon atmosphere to obtain a helical vanadium dioxide film.

Embodiment 3

[0025] In the chamber of the electron beam evaporation equipment, the angle between the substrate and the evaporation source is adjusted to 80 degrees while the substrate rotation speed is 64 revolutions per minute. Vanadium trioxide particles are used as the film material, the substrate temperature is room temperature, and the oxygen partial pressure is 3*10 -3 At Pa, a vanadium dioxide film is deposited on the FTO conductive glass substrate, and the deposited film is heat-treated at 400 degrees for 10 hours in a mixed atmosphere of air / nitrogen to obtain a C-type vanadium dioxide film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com