Device and method for remediation of in-situ fracturing aeration auxiliary electrochemical array well

A remediation method and electrochemical technology, applied in the field of in-situ remediation of polluted soil, can solve the problem of less industrial application of remediation equipment, and achieve the effects of improving remediation effect, high treatment efficiency and improving remediation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

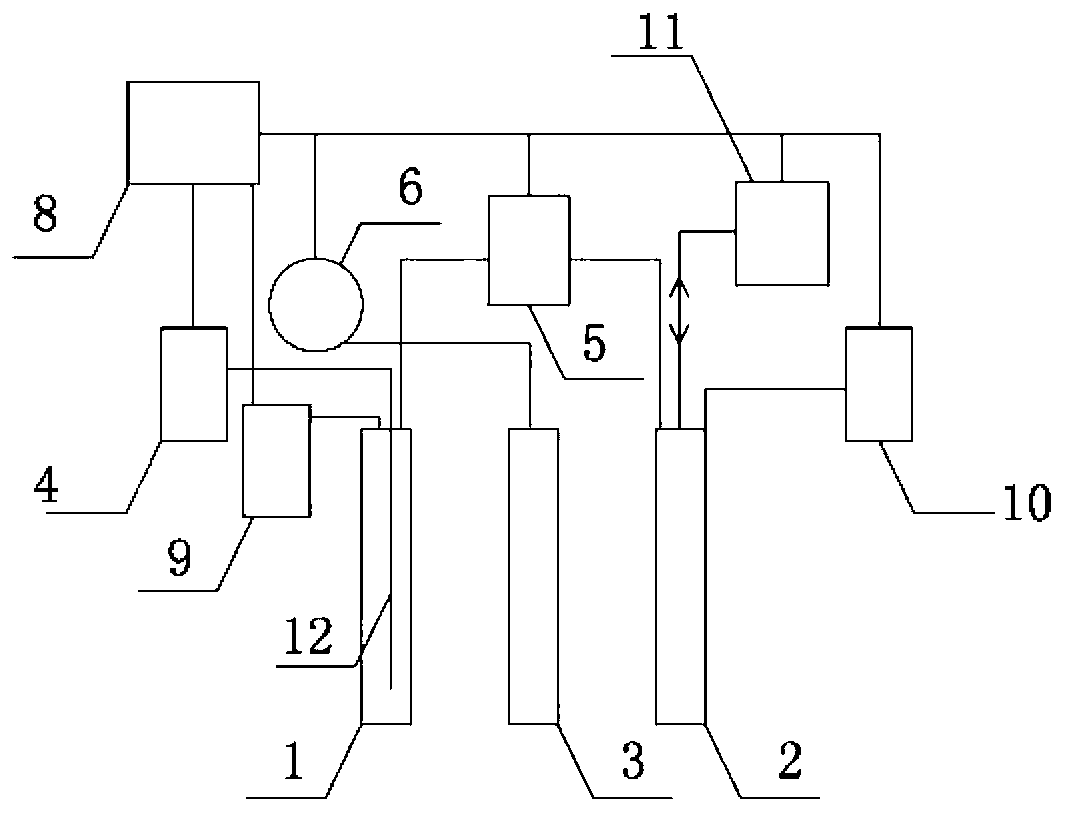

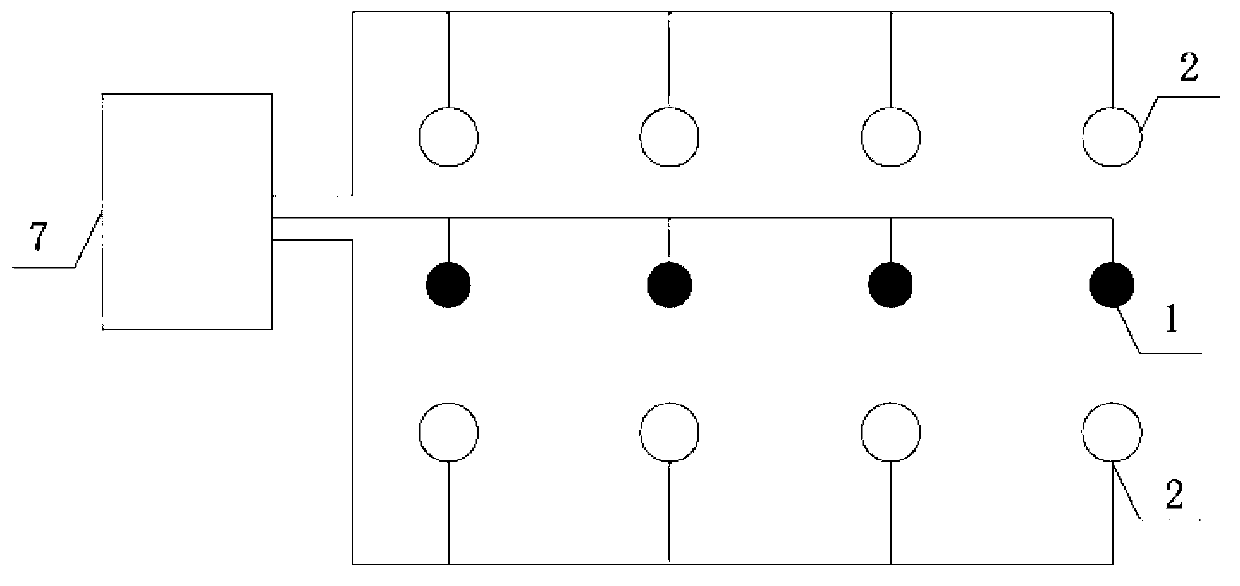

[0032] The present invention provides an in-situ fracturing aeration assisted electrochemical array well repair device and method. The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0033] An in-situ fracturing aeration assisted electrochemical array well repair device, its automatic control system 8 is connected to the air pump 4, the anode buffer dosing device 9 and the cathode buffer dosing device 10 respectively through lines, and the cathode buffer dosing device 10 is connected with the cathode buffer The lines connected to the liquid dosing device 10 are respectively connected to the high-pressure hydraulic fracturing pump 6, the suction pump waste gas treatment device 5 and the contaminated buffer solution treatment device 11;

[0034] The anode buffer dosing device 9 and the suction pump waste gas treatment device 5 are respectively connected to the anode well 1 through the line, and the air pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com