Catalyst regeneration method and device with catalytic cracking device heat replenished

A catalytic cracking device and catalyst technology, applied in the direction of catalyst regeneration/reactivation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as bed overheating, fuel oil injection unevenness, catalyst molecular sieve structure collapse, etc. , to achieve wide applicability, avoid severe local overheating, and great flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] The embodiment illustrates the method for supplementing the heat of the catalytic cracking unit provided by the present invention and the effect of the regenerator.

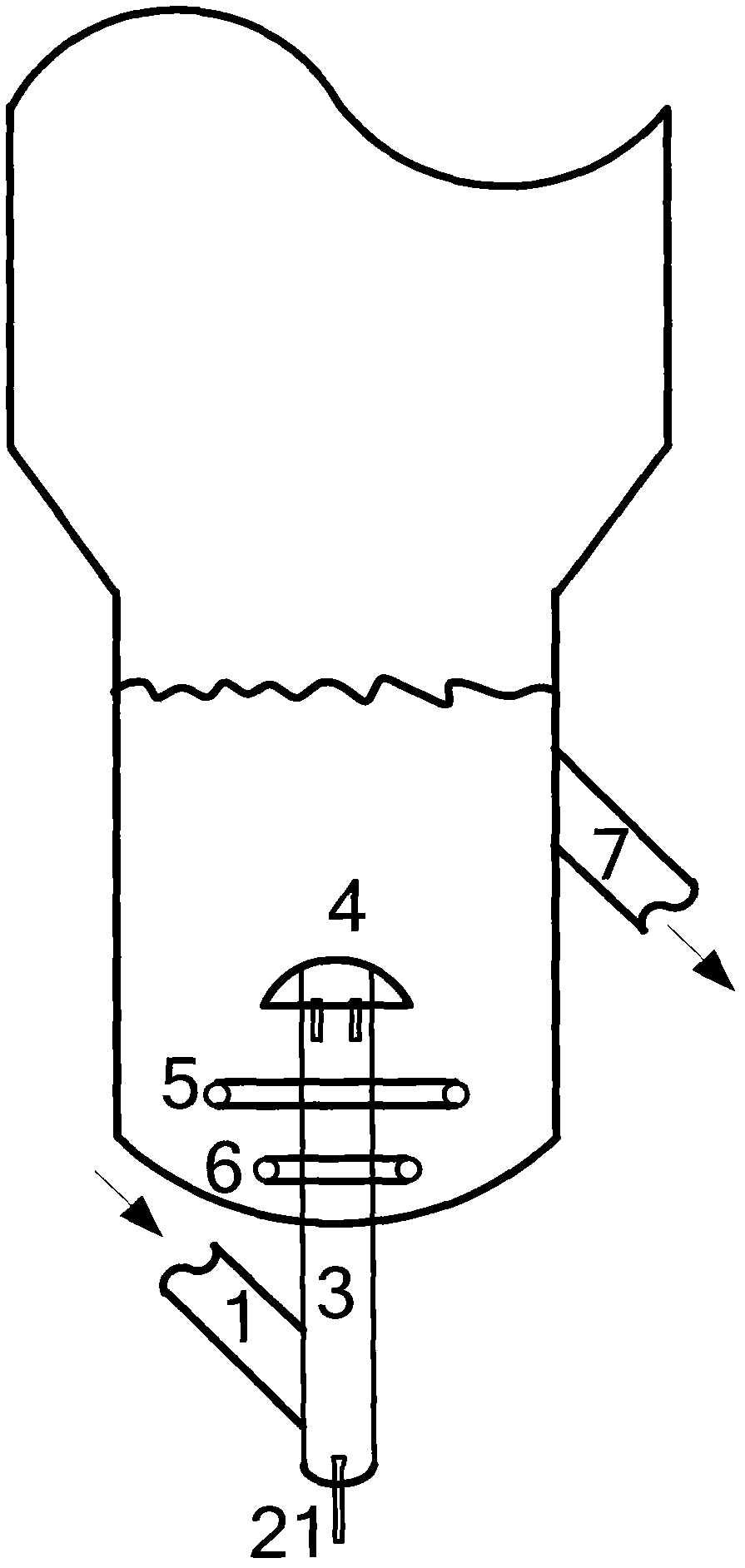

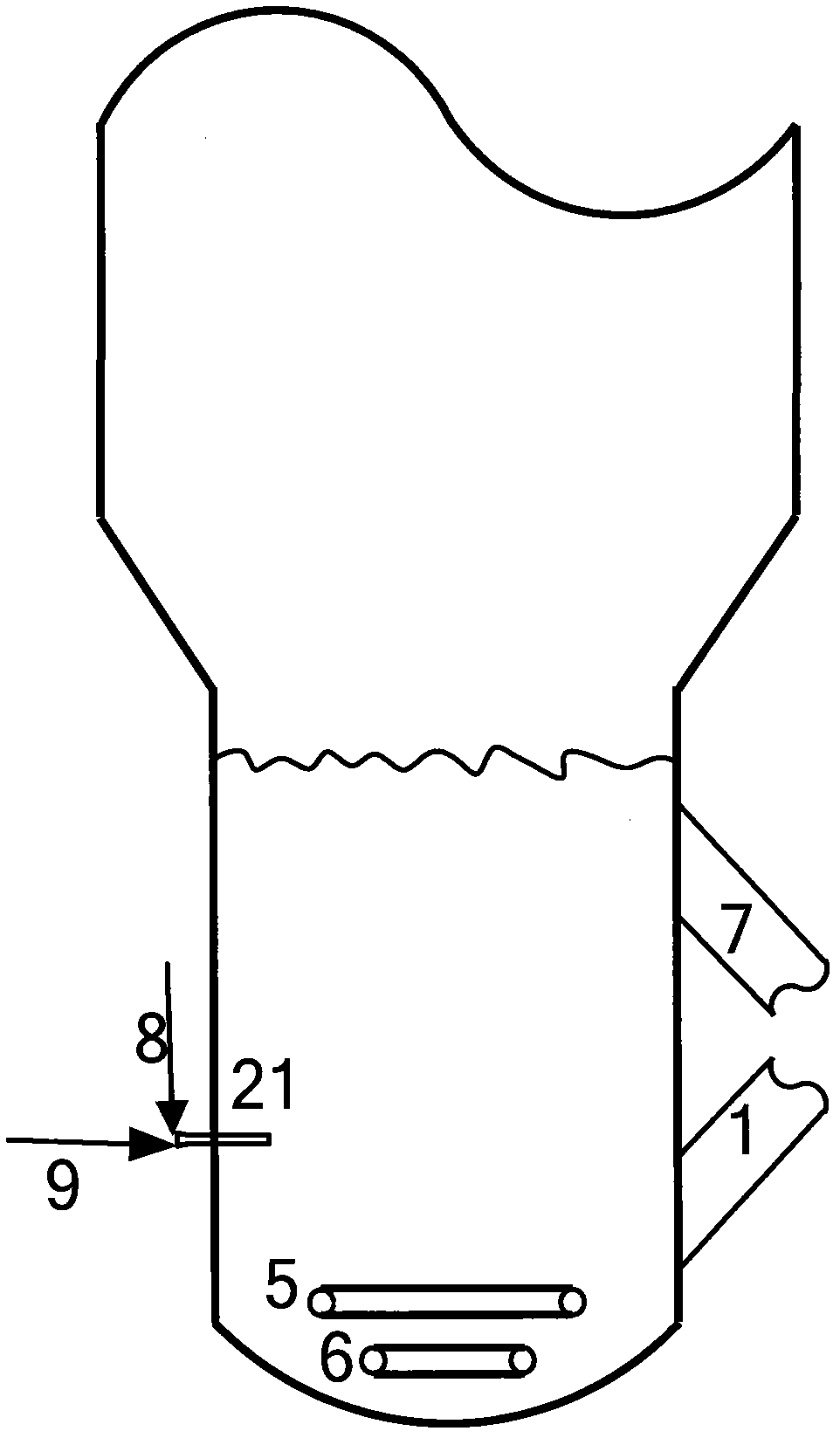

[0044] Naphtha is used as raw material to produce low-carbon olefins through catalytic cracking. The catalytic cracking catalyst is MMC-2. The test is carried out on a medium-sized riser reactor. The riser height is 5.5 meters and the pipe diameter is 16 mm. The structure of the regenerator is as attached figure 1 As shown, the standby catalyst enters the standby agent straight pipe 3 from the standby catalyst inclined pipe 1, diesel oil and steam are sprayed into the bottom of the standby agent straight pipe 3 through the nozzle 21, and after the standby catalyst is mixed evenly with the fuel oil steam, It enters the catalyst dense-phase bed of the regenerator through the umbrella-shaped distributor 4, and burns in contact with the oxygen-containing gas from the main air distributor 5 and 6, and the spent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com