Sewage treatment membrane separation unit, sewage treatment membrane module, and method for sewage treatment through utilizing membrane module

A technology for sewage treatment and membrane separation, applied in the field of environmental engineering, can solve the problems of ineffective use of heat, large system area, unfavorable protein separation, etc. The effect of reducing the concentration polarization phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] 1. Forward osmosis treatment

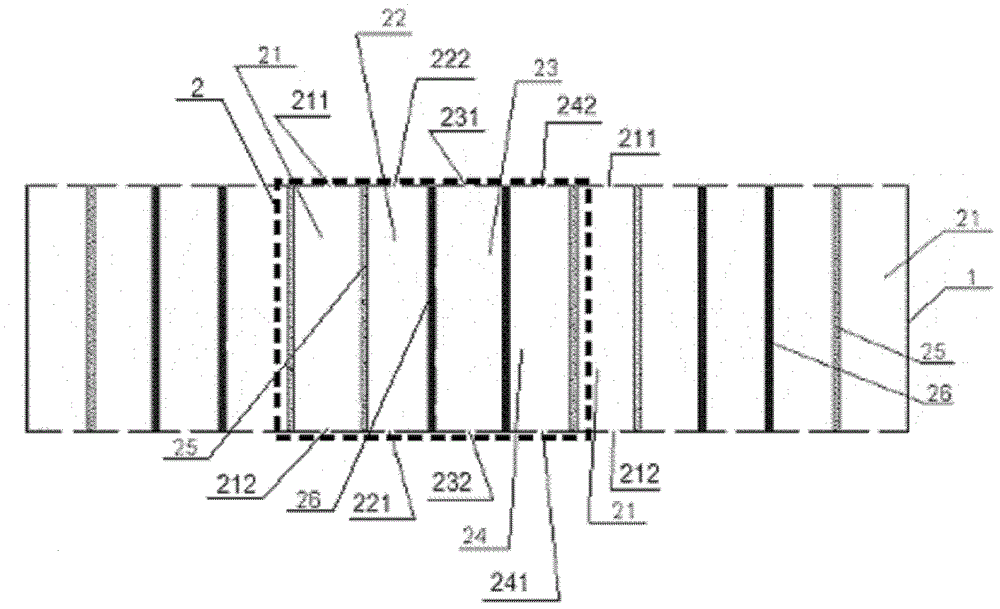

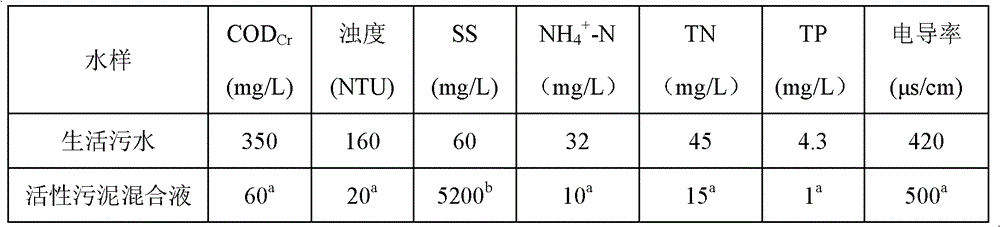

[0084] In this embodiment, 30 permeable membranes 25 and 30 microporous hydrophobic membranes 26 are used in the sewage treatment flat membrane module, that is, there are 15 membrane separation units 2 in the sewage treatment membrane module;

[0085] The activated sludge mixed solution flows into the sewage chamber of the membrane module from the inlet 211 of the sewage chamber 21 at a flow rate of 50 cm / s; the driving liquid sodium chloride solution flows from the first driving liquid chamber 22 to The inlet 221 and the inlet 241 of the second driving liquid chamber 24 flow into the first and second driving liquid chambers 22 and 24 of the membrane module, wherein the temperature of the sodium chloride solution is 40°C, the concentration is 1.5mol / L, and the flow rate is 50cm / s;

[0086] The activated sludge mixed liquid and the driving liquid are separated by the osmotic membrane 25. Due to the high osmotic pressure of the driving liq...

Embodiment 2

[0090] In the membrane module, except that 16 permeable membranes 25 and 16 microporous hydrophobic membranes 26 are used in total, that is, there are 8 membrane separation units 2 in the membrane module for sewage treatment, the rest are the same as in Example 1.

[0091] In the process of forward osmosis treatment, except that the flow rate of the sewage activated sludge mixture is 70cm / s; the concentration of the drive solution is 1.5mol / L, the temperature is 40°C, and the flow rate is 70cm / s; the average membrane effluent flux of the permeable membrane 25 4.8L / (m 2 · h) except that the others are the same as in Example 1.

[0092] During the membrane distillation process, except that the temperature of the clear water is 8°C, the flow rate is 50cm / s; the average membrane water flux of the hydrophobic microporous membrane 26 is 4.8L / (m 2 · h) except that the others are the same as in Example 1.

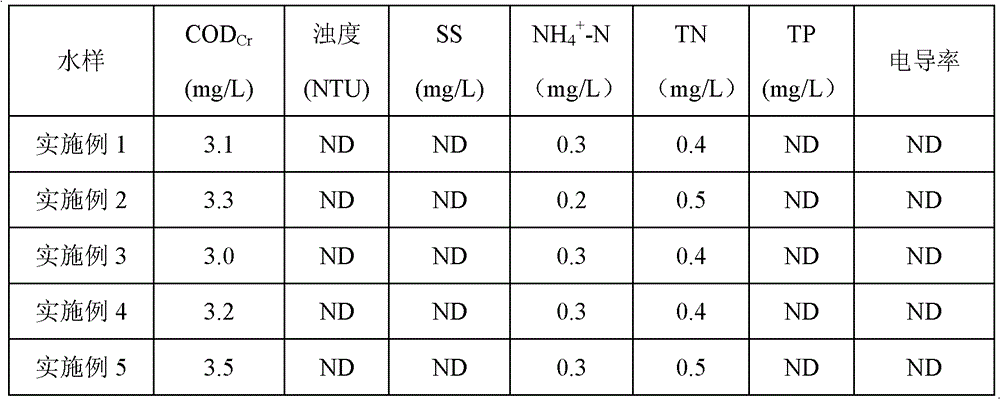

[0093] The water quality performance testing indicators of the treated efflu...

Embodiment 3

[0095] In the membrane module, except that 16 permeable membranes 25 and 16 microporous hydrophobic membranes 26 are used in total, that is, there are 8 membrane separation units 2 in the membrane module for sewage treatment, the rest are the same as in Example 1.

[0096] In the forward osmosis treatment process, except that the flow rate of the sewage activated sludge mixture is 10cm / s; the concentration of the drive solution is 1.5mol / L, the temperature is 40°C, and the flow rate is 70cm / s; the average membrane effluent flux of the permeable membrane 25 3.9L / (m 2 · h) except that the others are the same as in Example 1.

[0097] During the membrane distillation process, except that the temperature of the clear water is 8°C, the flow rate is 15cm / s; the average membrane water flux of the hydrophobic microporous membrane 26 is 4.0L / (m 2 · h) except that the others are the same as in Example 1.

[0098] The water quality performance testing indicators of the treated effluent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com