Fiberboard preservative

A preservative and fiberboard technology, applied in biocides, disinfectants, bactericides, etc., can solve the problems of preservative toxicity, unfavorable environmental protection, etc., and achieve the effects of preventing precipitation, moderate price, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

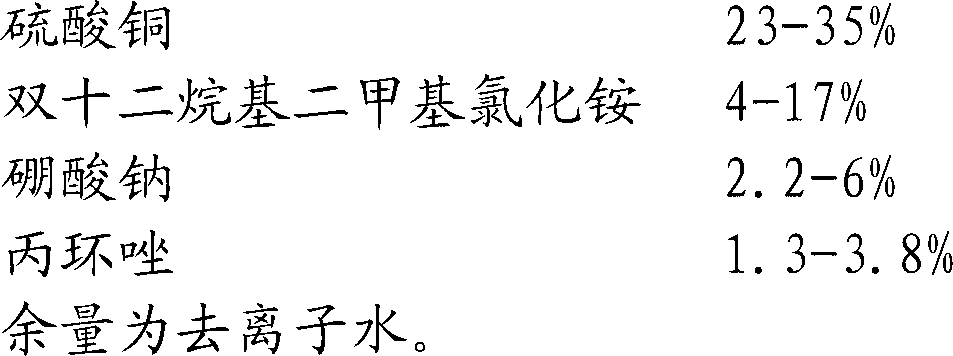

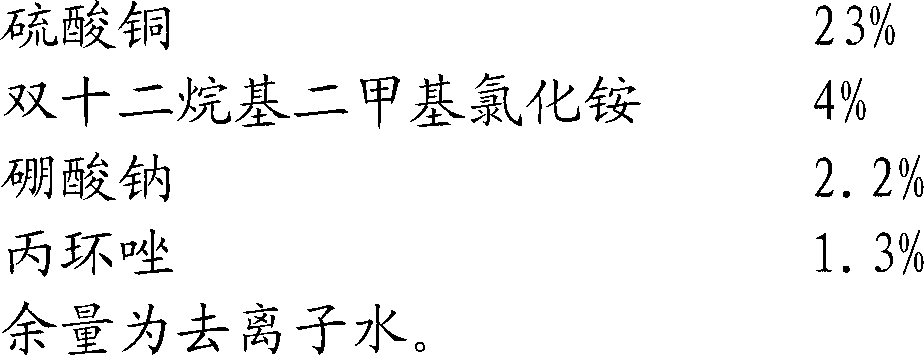

[0013] The fiberboard preservative of the present embodiment is made up of the following components by weight percentage

[0014]

[0015] The preparation method of the fiberboard preservative of the present embodiment may further comprise the steps:

[0016] (1) Mix 4% didodecyldimethyl ammonium chloride, 2.2% sodium borate, 1.3% propiconazole and appropriate amount of deionized water, heat the mixture to 100-110°C, and keep stirring until the solid is completely dissolve;

[0017] (2) After cooling to room temperature, add 23% copper sulfate, and finally add deionized water to make the total weight percentage 100%;

[0018] (3) Stir until all components are completely dissolved.

Embodiment 2

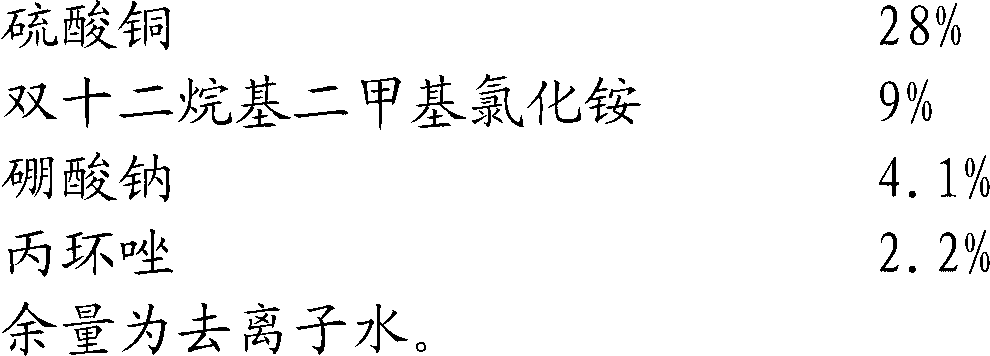

[0020] The fiberboard preservative of the present embodiment is made up of the component of following percentage by weight:

[0021]

[0022] The preparation method of the fiberboard preservative of the present embodiment may further comprise the steps:

[0023] (1) Mix 9% didodecyldimethyl ammonium chloride, 4.1% sodium borate, 2.2% propiconazole and appropriate amount of deionized water, heat the mixture to 100-110°C, and keep stirring until the solid is completely dissolve;

[0024] (2) After cooling to room temperature, add 28% copper sulfate, and finally add deionized water to make the total weight percentage 100%;

[0025] (3) Stir until all components are completely dissolved.

Embodiment 3

[0027] The fiberboard preservative of the present embodiment is made up of the following components by weight percentage

[0028]

[0029] The preparation method of the fiberboard preservative of the present embodiment may further comprise the steps:

[0030] (1) Mix 14.5% didodecyldimethyl ammonium chloride, 5.0% sodium borate, 3.3% propiconazole and appropriate amount of deionized water, heat the mixture to 100-110°C, and keep stirring until the solid is completely dissolve;

[0031] (2) After cooling to room temperature, add 30% copper sulfate, and finally add deionized water to make the total weight percentage 100%;

[0032] (3) Stir until all components are completely dissolved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com