Display panel and electrowetting display equipment

An electrowetting display and display panel technology, used in static indicators, optics, instruments, etc., can solve the problems of low brightness, increased production process steps, small color gamut, etc., and achieve high luminous purity, high display quality, and large size. The effect of color gamut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the display panel and the electrowetting display device of the present invention will be further described in detail below with reference to the drawings and specific embodiments.

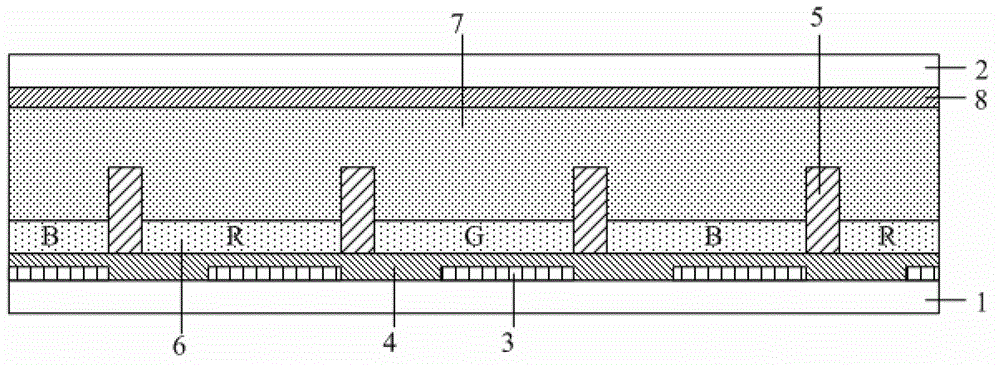

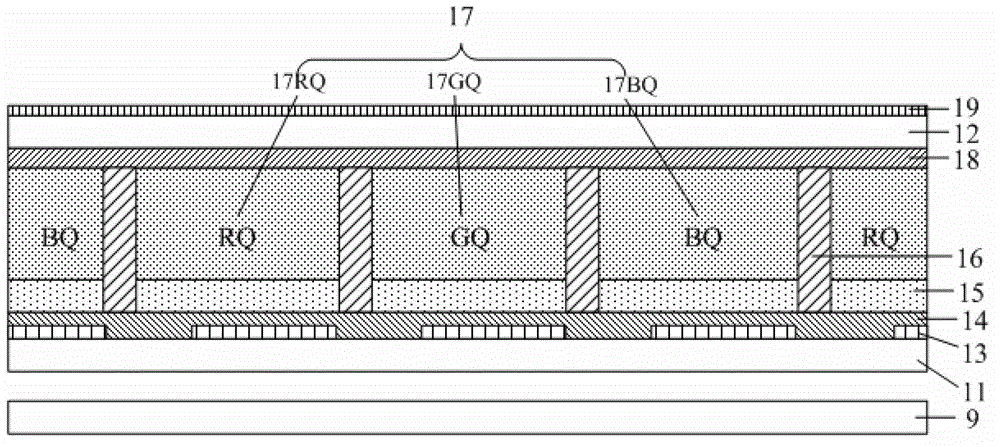

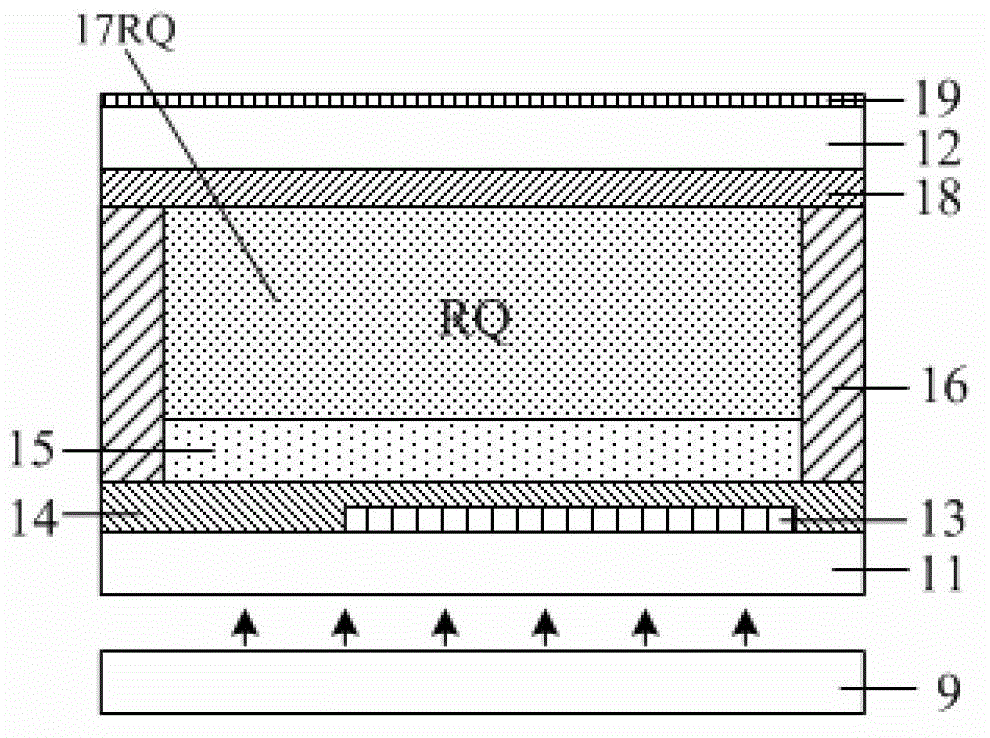

[0025] A display panel, comprising a pixel electrode substrate, a common electrode substrate, a plurality of pixel electrodes, a dielectric layer and a barrier plate, the plurality of pixel electrodes are arranged on the pixel electrode substrate at intervals, and the dielectric layer is arranged on the on the pixel electrode substrate and make the pixel electrode embedded therein, the barrier plate is located between the adjacent pixel electrodes, the display panel also includes a non-polar liquid capable of absorbing ultraviolet light and the polarity of the sub-dots liquid, the non-polar liquid and the polar liquid are sequentially arranged on the dielectric layer in the space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com