Device for conveying high-viscosity material

A high-viscosity, high-material technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve problems such as unfavorable equipment layout, easy blockage of pipelines, long suction pipeline of horizontal pumps, etc., and achieve favorable equipment layout , Convenient equipment maintenance, saving operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

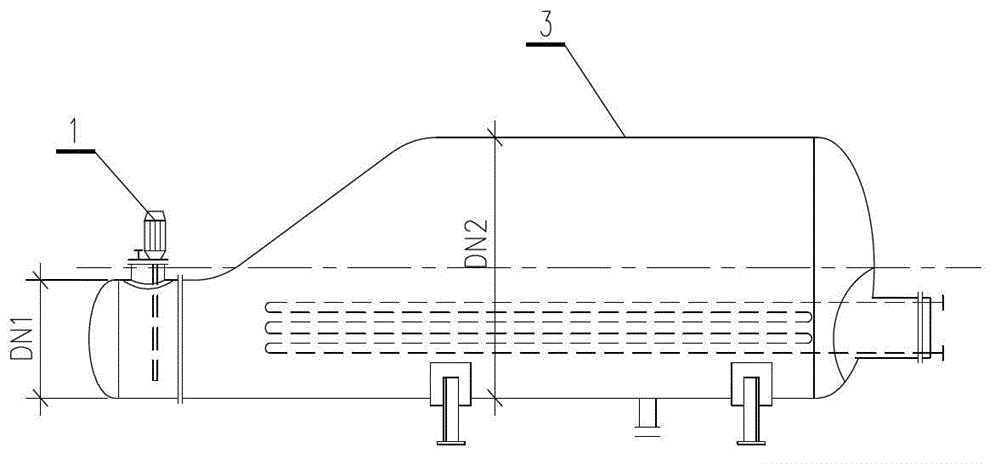

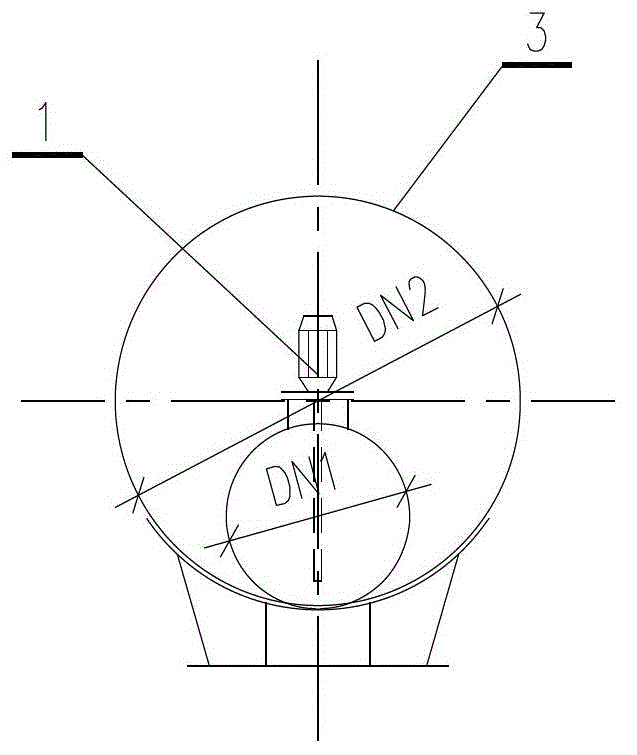

[0024] Embodiment 1: The diameter of one end of the horizontal tank 3 is reduced, the nominal diameter DN1 of the reduced diameter part is between 1m-1.8m, and an interface is opened on the upper part of the reduced tank body to connect with the short-axis submerged pump 1, so that the horizontal The type tank 3 and the short-axis submerged pump 1 become an integral structure, see Figure 4 .

Embodiment 2

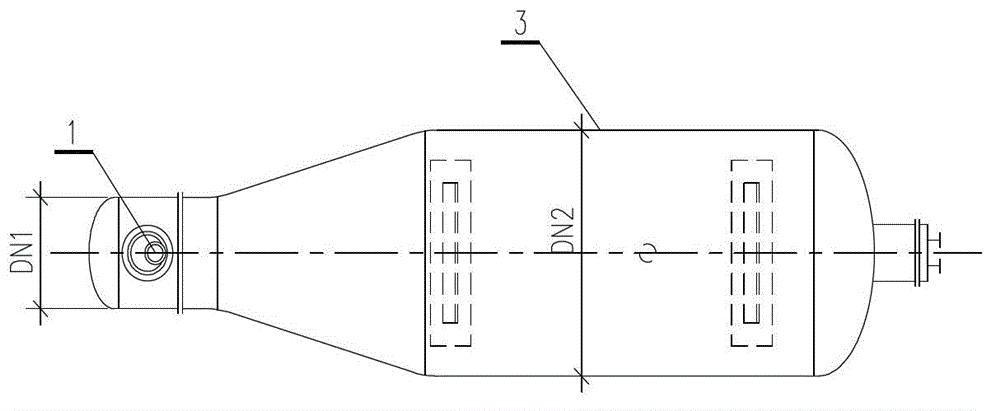

[0025] Example 2: Make a middle tank 2, open an interface on the top of the middle tank 2, and connect it with the short-axis submerged pump 1, so that the middle tank 2 and the short-axis submerged pump 1 form an integrated structure, and the middle tank 2 and the vertical tank 4 connections, the nominal diameter DN1 of the middle groove 2 is between 1m-1.8m, see Figure 5 .

[0026] The medium conveyed by the present invention not only refers to asphalt, but also transports high-viscosity materials with similar physical properties to asphalt. The use of short-axis submerged pumps can save operating space, facilitate equipment maintenance, and facilitate equipment layout; by changing the structure of the storage tank or adding an intermediate tank, the problem of easy blockage of the pipeline is solved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal diameter | aaaaa | aaaaa |

| Nominal diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com