Jacking device of tunnel measuring hole and construction method thereof

A technology of a jacking device and a construction method, which is applied to tunnels, earth-moving drilling, mining equipment, etc., can solve problems such as affecting the construction efficiency and progress of the project, failing to successfully complete the tunnel penetration work due to large accumulated errors, and construction engineering accidents, etc. Achieve high construction efficiency, small error, and improve the effect of error control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

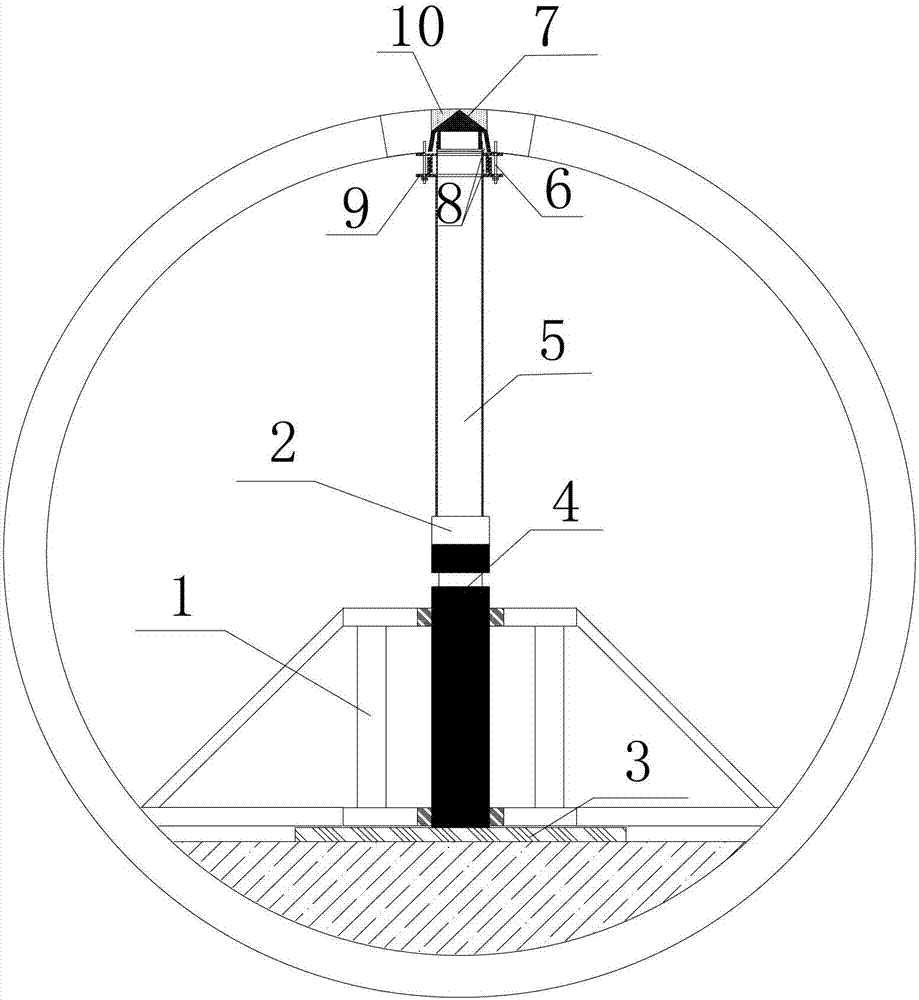

[0041] A jacking device for a tunnel measuring hole, including a pre-embedded part, a water stop ring, a steel pipe and a jack; The bottom is supported by jack 4. The jack 4 is supported by the oil cylinder support 1, and the bottom is provided with a steel running board 3.

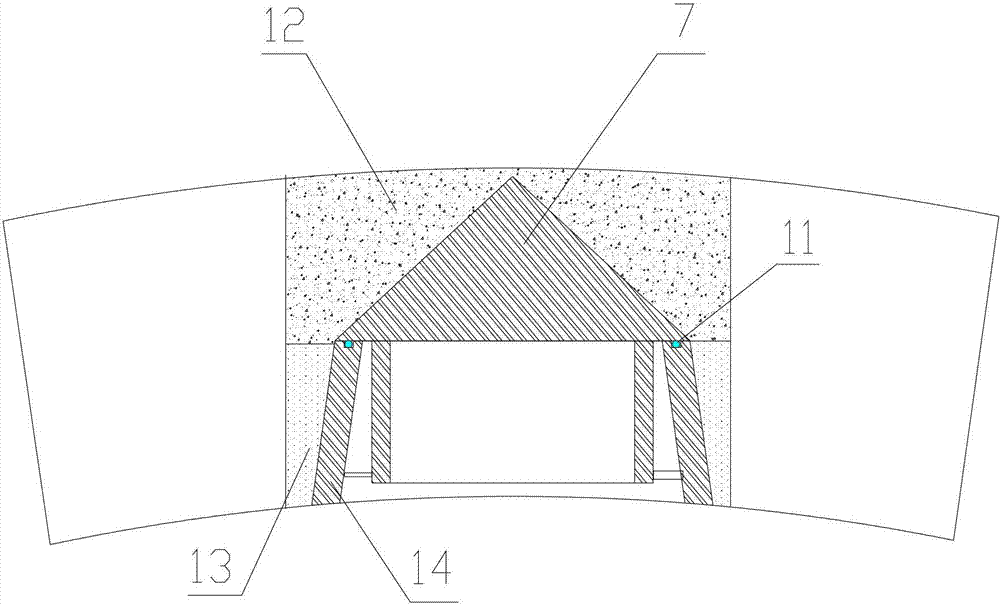

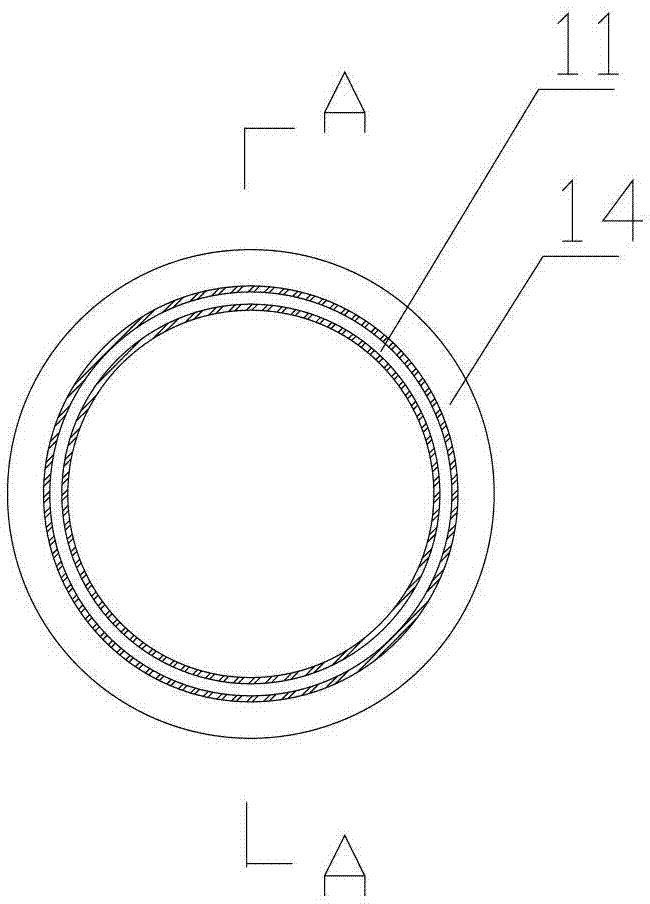

[0042] The embedded part is composed of a limit steel ring 14 and a jacking bit 7, and the jacking bit 7 is composed of a jacking bit cap 7.1 and a jacking bit supporting steel ring 7.2, and the limit steel ring 14 is located under the jacking bit cap 7.1, located Jacking drill bit supports steel ring 7.2 outsides. The upper end surface of the limiting steel ring 14 in contact with the jacking drill cap 7.1 is provided with a sealing groove, and an O-shaped sealing ring 11 is housed in the sealing groove.

[0043] The water stop ring is composed of an upper water stop ring 15 and a lower water stop ring 9, the upper water stop ring 15 and the lower water stop ring 9 are respectively composed of a limit ...

Embodiment 2

[0045] A construction method for jacking up a tunnel measuring hole, including the embedding of embedded parts, the fixed installation of the jacking equipment frame, the installation of the water stop ring, and the jacking process of steel pipe welding:

[0046] Embedding of embedded parts: embed the embedded parts in the segment in advance, weld the surrounding steel bars firmly with the segment, and add reinforcing ribs at the opening; then fill the gap with fine stone concrete;

[0047] Fixed installation of the jacking equipment frame: install the jacking equipment, which is supported and fixed by the cylinder bracket; the jacking equipment is a 100-300 ton double-stroke jack, the jack stroke is 3-5m, and a steel running board is installed at the bottom of the jack.

[0048] Water stop ring installation: the water stop ring is nested and installed on the steel pipe, and assembled together by tensioning mechanism;

[0049] Steel pipe welding jacking: use seamless steel pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com