Shaft-disc coordinate deviation measuring method for slotted welding impeller

A technology of coordinate deviation and measurement method, which is applied in the field of compressors, and can solve problems such as complicated measurement steps of a three-coordinate measuring instrument, high cost of a three-coordinate measuring instrument, and small internal space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

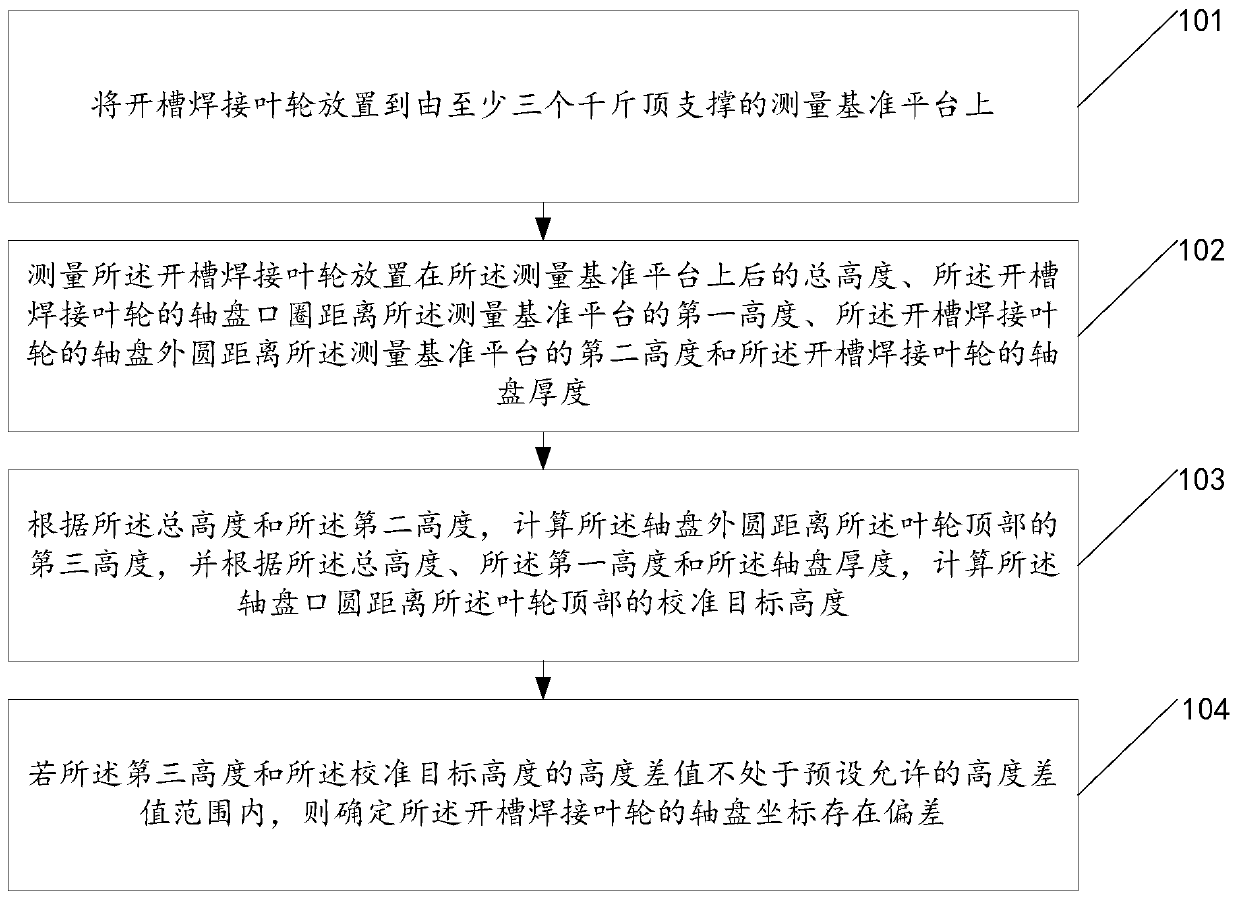

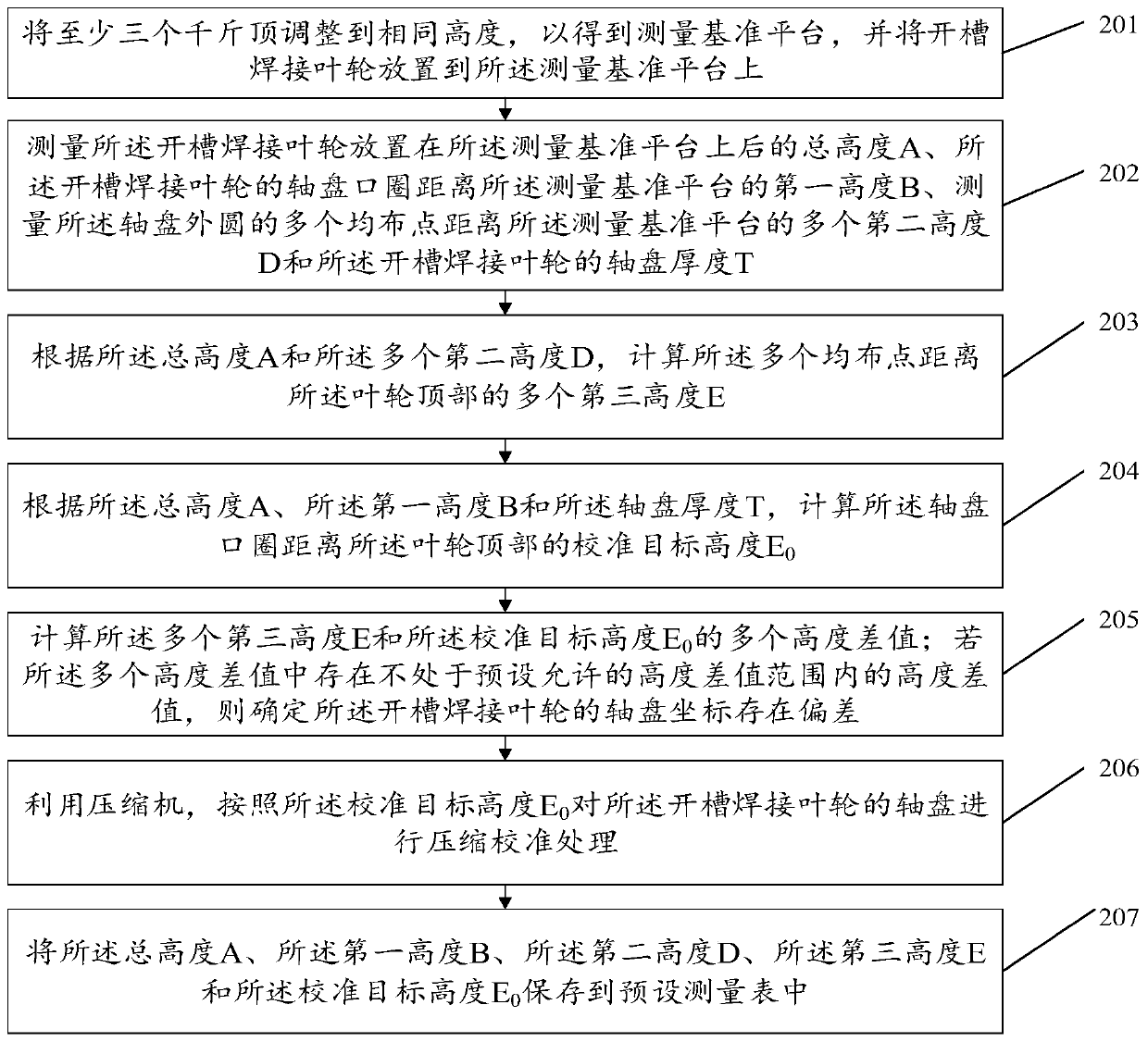

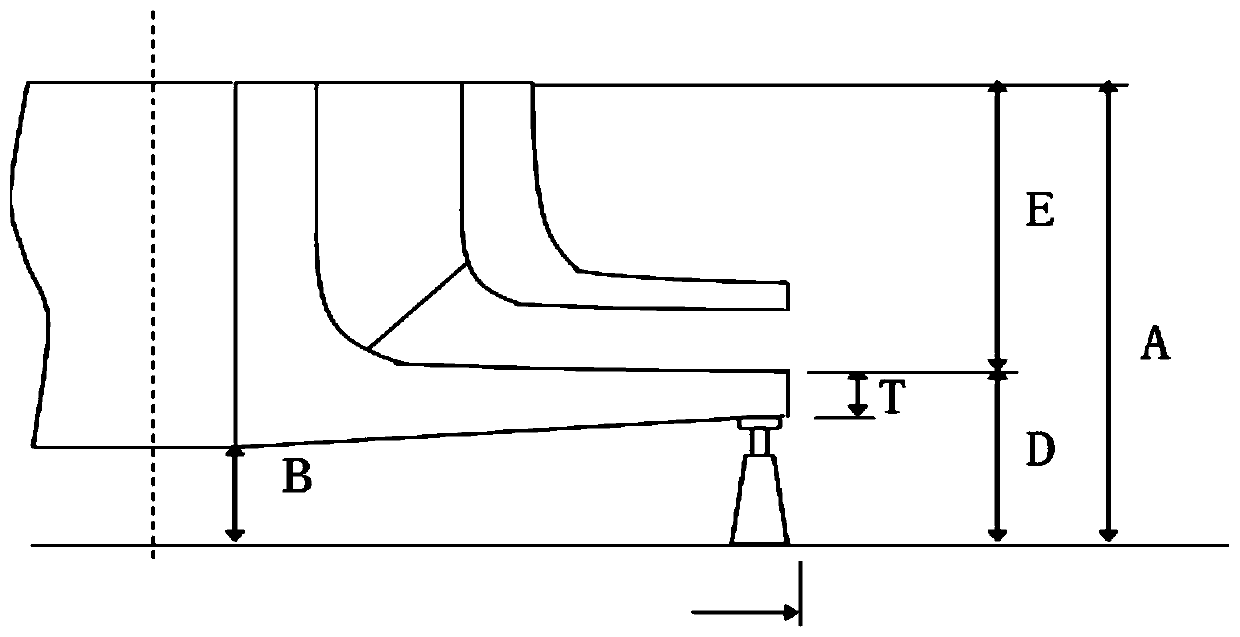

Method used

Image

Examples

Embodiment Construction

[0017] Exemplary embodiments of the present disclosure will be described in more detail below with reference to the accompanying drawings. While exemplary embodiments of the present disclosure are shown in the drawings, it should be understood that the present disclosure may be embodied in various forms and should not be limited by the embodiments set forth herein. Rather, these embodiments are provided so that the present disclosure will be more thoroughly understood, and will fully convey the scope of the present disclosure to those skilled in the art.

[0018] As described in the background art, at present, a three-coordinate measuring instrument can be used to measure the shaft-disk coordinate deviation of a slotted welded impeller. However, due to the small internal space of the slotted welded impeller flow channel, the large output of the slotted welded impeller, and the complicated measurement steps of the CMM, it will consume a lot of manpower if each impeller uses a C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com