A large amount of fly ash composite self-insulating block and its preparation method

A self-insulating block and fly ash technology, applied in the direction of sustainable waste treatment, solid waste management, climate change adaptation, etc., can solve the problems of thermal insulation, heat insulation, energy saving, durability, ecological environment and natural environment Problems such as landscape damage and high block damage rate are achieved, which is beneficial to environmental protection, has obvious energy-saving effects, and reduces project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

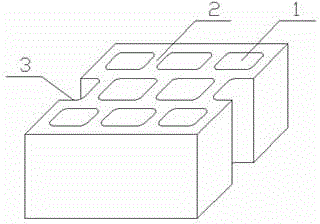

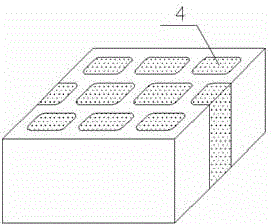

[0012] Such as figure 1 figure 2 As shown, the large-volume fly ash composite self-insulating block of the present invention includes a rectangular block body 2 with eight through holes 1 formed by extrusion, and the through holes are arranged in three rows up and down, parallel and staggered. Wherein the first row and the third row are the same, all are three rectangular longitudinal through holes, the second row is two rectangular longitudinal through holes plus two longitudinal semi-open through holes, and each row of holes has a hole wall interval. The left and right sides of the rectangular block body 2 are symmetrically opened with semi-open through-holes 3 , and thermal insulation materials 4 are filled in the semi-open through-holes 3 and the plurality of through-holes 1 .

[0013] The preparation method of the large-volume fly ash composite self-insulating block of the present invention: firstly, fly ash, Portland cement, and fly ash ceramsite are crushed in a rolle...

Embodiment 2

[0015] Such as figure 1 figure 2 As shown, while extruding a rectangular block body with eight through holes, semi-open through holes are symmetrically extruded on its left and right sides. The cross section of the through holes is rectangular. The first row and the third row are the same, all are three rectangular longitudinal through holes, the second row is two rectangular longitudinal through holes plus two longitudinal semi-open through holes, and each row of holes has a hole wall interval. The semi-open through hole and multiple through holes are filled with insulation material mixed with rice husk, Portland cement and 901 glue according to the mass percentage, compacted, leveled, and prepared after natural curing.

[0016] Preparation method of large-volume fly ash composite self-insulating block: by mass percentage, the fly ash is 43.4%, Portland cement is 16.9%, fly ash ceramsite is 33.9%, and water is 5.8% . Filling material preparation method: In terms of mass p...

Embodiment 3

[0018] Such as figure 1 figure 2 As shown, while extruding a rectangular block body with eight through holes, semi-open through holes are symmetrically extruded on its left and right sides. The cross section of the through holes is rectangular. Wherein the first row and the third row are the same, all are three rectangular longitudinal through holes, the second row is two rectangular longitudinal through holes plus two longitudinal semi-open through holes, and each row of holes has a hole wall interval. The semi-open through hole and multiple through holes are filled with insulation material mixed with rice husk, Portland cement and 901 glue according to the mass percentage, compacted, leveled, and prepared after natural curing. The cycle of natural conservation is about 28 days. Care should be taken to keep the blocks moist during maintenance, especially in dry and hot climates, to prevent cracks on the surface of the blocks.

[0019] Preparation method of large-volume fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com