Light and cool fabric for clothing of medical staff

A light and cool fabric technology, applied in clothing, apparel, applications, etc., can solve the problem of small size changes, and achieve the effect of fine tissue structure, small specific heat capacity and thermal conductivity, and beautiful posture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

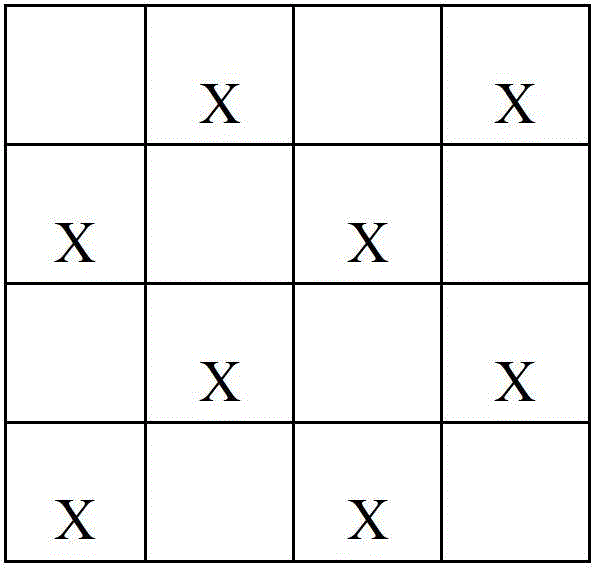

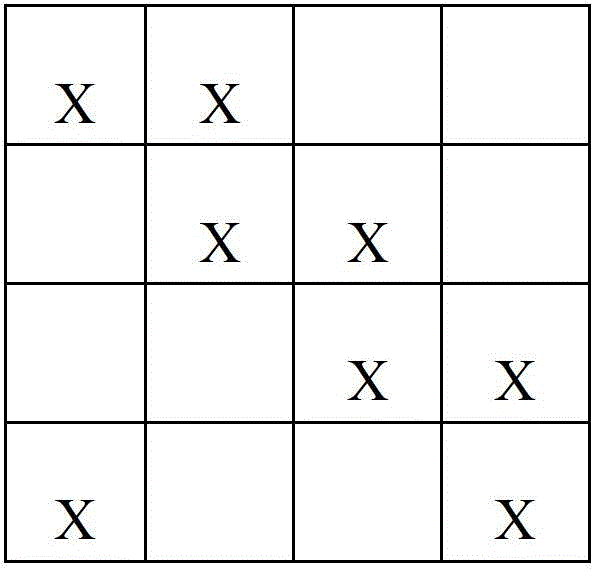

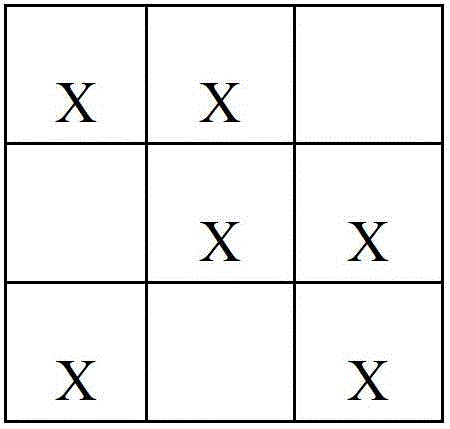

[0025] T65 / C35, 30s combed polyester-cotton yarn is used as the warp yarn, 150-167D / 144F full-dull polyester filament is used as the weft yarn, and 2 anti-static silk conductive yarns are evenly added to the warp direction per inch, and the twill weave method of two-up and one-down is adopted , to make a medical clothing fabric with a warp density of 512 threads / 10cm and a weft density of 291 threads / 10cm.

[0026] The prepared fabric is moderate in thickness, beautiful, comfortable, protective, washable, and sterilizable. After wearing it for a month, 50 medical staff commented that it is beautiful, dry, breathable, soft, skin-friendly and comfortable, and splash-proof. The size change of water washing is about -0.7 vertically and -0.2 horizontally. Antistatic performance: the surface charge density before washing is 1.7 (μc / m 2 ), the surface charge density after washing is 2.3 (μc / m 2 ) with antistatic durability.

Embodiment 2

[0028] T65 / C35, 32s combed polyester-cotton yarn is used as the warp yarn, 150-167D / 144F full-dull polyester filament is used as the weft yarn, and 2 anti-static silk conductive yarns are evenly added to the warp direction per inch, and the twill weave method of two-up and one-down is adopted , to make a medical clothing fabric with a warp density of 512 threads / 10cm and a weft density of 276 threads / 10cm.

[0029] The prepared fabric is light, beautiful, comfortable, protective, washable, and sterilizable. After wearing it for a month, 50 medical staff commented that it has good air permeability and is skin-friendly, soft and comfortable. The size change of water washing is about -1.1 vertically and -0.9 horizontally. Anti-static performance: the surface charge density before washing is 1.8 (μc / m 2 ), the surface charge density after washing is 2.4 (μc / m 2 ) with antistatic durability.

Embodiment 3

[0031] T65 / C35, 30s combed polyester-cotton yarn is used as the warp yarn, 150-167D / 96F full-dull polyester filament is used as the weft yarn, and 2 anti-static silk conductive yarns are evenly added to the warp direction per inch, and the twill weave method of two-up and one-down is adopted , to make a medical clothing fabric with a warp density of 512 threads / 10cm and a weft density of 291 threads / 10cm.

[0032] The prepared fabric is moderate in thickness, beautiful, comfortable, protective, washable, and sterilizable. After wearing it for two weeks, 50 medical staff commented that it is crisp, less wrinkled, beautiful, comfortable, and good in protection. The size change of water washing is about -0.8 vertically and -0.3 horizontally. Antistatic performance: the surface charge density before washing is 1.7 (μc / m 2 ), the surface charge density after washing is 2.2 (μc / m 2 ) with antistatic durability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com