Near-dry cutting oil for aluminum alloy and preparation method thereof

A quasi-dry cutting, aluminum alloy technology, applied in the field of aluminum alloy quasi-dry cutting oil and its preparation, can solve the problems affecting the health of operators, large amount of lubricants, processing places and environmental pollution, etc., and achieve environmental protection benefits Significant, good extreme pressure properties, good lubrication and cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

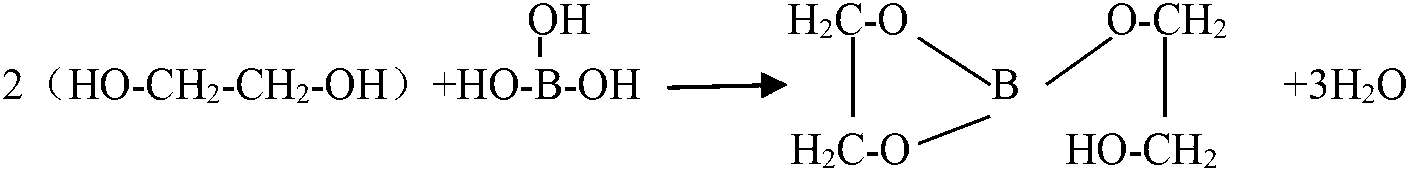

[0042] Step 1: Weigh 124.136kg (2000mol) of ethylene glycol and 61.83kg (1000mol) of boric acid into the reaction kettle, fill it with nitrogen protection, heat and stir to 180°C, keep stirring at a constant temperature for 4 hours, depressurize and discharge the water generated by the reaction, and prepare two Ethylene glycol borate for use;

[0043] Step 2: take by weighing the diethylene glycol borate ester 138kg (1000mol) that step 1 reacts to generate and the octanoic acid of 144.24kg is put into reactor, then add the strongly acidic cation exchange resin of 5kg (001×7 strongly acidic styrene series cation exchange resin) as a catalyst, filled with nitrogen for protection, stirred and heated to 200°C, kept stirring at a constant temperature for 4 hours, decompressed and discharged the water generated by the reaction, and removed the cation exchange resin to obtain diethylene glycol octanoic acid borate (containing a small amount of ethyl diol dicaprylate and boric acid); ...

Embodiment 2

[0050] Step 1: Weigh 124.136kg (2000mol) of ethylene glycol and 98kg (1000mol) of phosphoric acid into the reactor, fill it with nitrogen protection, heat and stir to 110°C, keep stirring at a constant temperature for about 3 hours, depressurize and discharge the water generated by the reaction, and prepare two Ethylene glycol phosphate spare;

[0051]Step 2: Take 174kg (1000mol) of diethylene glycol phosphate produced by the reaction in step 1 and add it to the reactor, weigh 200.32kg (1000mol) of lauric acid and add it to the reactor for mixing and stirring, and then add 7kg of strong acidic cation exchange resin (D001 macroporous strongly acidic styrene-based cation exchange resin) as a catalyst, filled with nitrogen protection, stirred and heated to 220 ° C, kept stirring at a constant temperature for 3 hours, decompressed to discharge the water generated by the reaction, and removed the cation exchange resin to obtain diethyl ether Glycol laurate phosphate (contains small...

Embodiment 3

[0058] Step 1: Weigh 124.136kg (2000mol) of ethylene glycol and 61.83kg (1000mol) of boric acid into the reaction kettle, fill it with nitrogen protection, heat and stir to 160°C, keep stirring at a constant temperature for 4.5 hours, depressurize and discharge the water generated by the reaction, and prepare two Ethylene glycol borate for use;

[0059] Step 2: take by weighing the diethylene glycol borate ester 138kg (1000mol) that step 1 reacts and generate and the decanoic acid of 172.27kg (1000mol) is put into reactor, then add the strongly acidic cation exchange resin of 5kg (001×7 strongly acidic Styrene-based cation-exchange resin) as a catalyst, filled with nitrogen protection, stirred and heated to 220 ° C, kept stirring at a constant temperature for 3 hours, decompressed and discharged the water generated by the reaction, and removed the cation-exchange resin to obtain diethylene glycol decanoic acid boric acid Esters (contains small amounts of ethylene glycol dideca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com