Nano anti-wear agent, and preparing method and use thereof

A nano-anti-wear and carbon nano-tube technology, which is applied in the direction of additives, petroleum industry, lubricating compositions, etc., can solve the problems of no anti-wear and anti-friction characteristics, and promote wear, so as to achieve extended service life, good extreme pressure, and friction The effect of low coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0017] Example 1. Nano antiwear agent

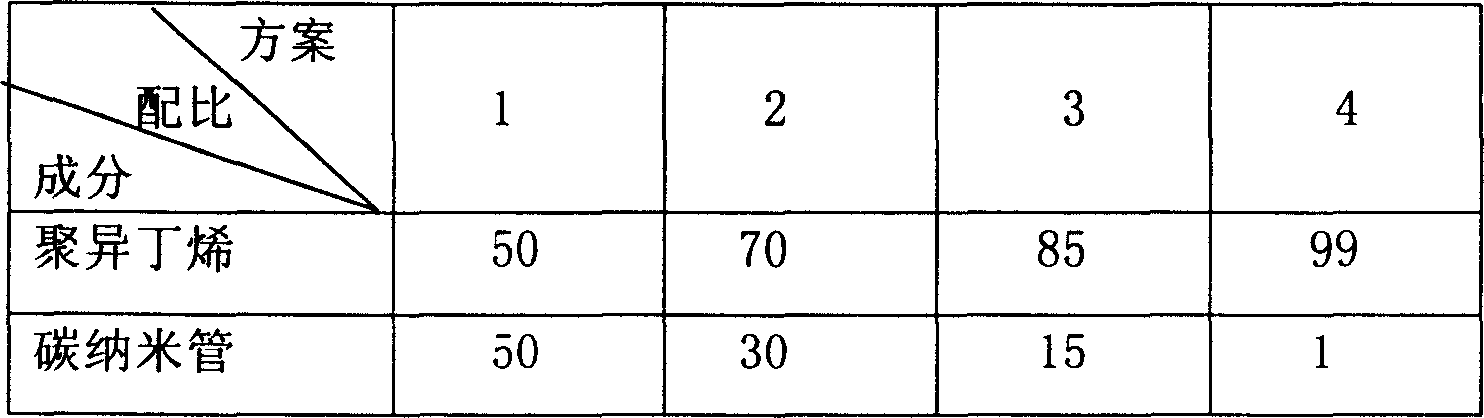

[0018] 1. Composition: The weight percentages of polyisobutylene and carbon nanotubes are 50-99 and 1-50 respectively.

[0019] 2. the method for preparing nanometer antiwear agent, its step comprises:

[0020] (1) Mix polyisobutylene and carbon nanotubes in proportion, and the weight percentages are 50-99 and 1-50 respectively (see attached table),

[0021] (2) Stir evenly, or put into a ball mill to mix well,

[0022] (3) Grind in a three-roll mill, or disperse with an ultrasonic machine for 25 to 35 minutes.

[0023] The following steps may also be included:

[0024] (4) heat insulation and heating to reconcile, this step can speed up the reconciliation. The heating temperature is generally controlled at 40-90°C for 10-20 minutes.

[0025] The prepared product is the concentrated solution of the nanometer antiwear agent.

example 2

[0026] Example 2. Nano lubricating oil

[0027] 1. Composition: The weight percentages of nano antiwear agent and carbon nanotube are 3 and 97 respectively.

[0028] 2. Preparation method: mix the two materials of nanometer anti-wear agent and lubricating oil in proportion, stir them evenly, or make them after heat insulation, heating, reconciliation and cooling.

[0029] The nanometer anti-wear agent of example 1 is selected for use, which is a concentrated solution.

example 3

[0030] Example 3. Engine automatic repair agent

[0031] 1. Composition: the weight percentages of nano antiwear agent and lubricating oil are 80 and 20 respectively.

[0032] 2. Preparation method: mix the two materials of nanometer anti-wear agent and lubricating oil in proportion, stir them evenly, or make them after heat insulation, heating, reconciliation and cooling.

[0033] The nanometer anti-wear agent of example 1 is selected for use, which is a concentrated solution.

[0034] 2. Schedule

[0035] Composition and proportioning (weight %) of nano antiwear agent

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com