Diesel oil lubricity improving agent

An improver and lubricity technology, applied in the field of environment-friendly diesel lubricity improver, to achieve the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

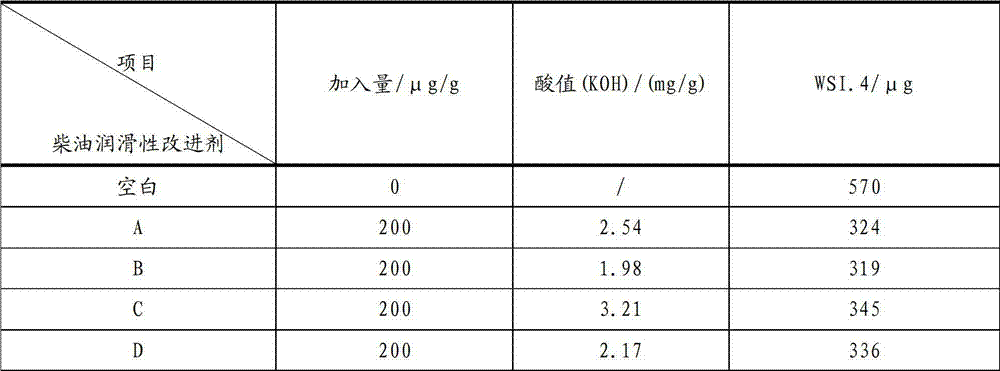

Image

Examples

Embodiment 1

[0021] Synthesis of fatty acid monoester and fatty acid diester mixture: Add 28.25g oleic acid, 18.6g ethylene glycol, 0.4g p-toluenesulfonic acid to start stirring in sequence in a reactor with a thermometer, condenser, and stirrer, and pass into Nitrogen, gradually increase the temperature to 120-150°C, and distill the water generated by the reaction at this temperature, react for 4-5 hours, stop the reaction if no water evaporates, cool to room temperature and let it stand until the product settles and separates , the obtained upper product is the target product, and the esterification rate of fatty acid is 97.3%.

Embodiment 2

[0023] The synthesis of fatty acid monoester and fatty acid diester mixture: add 28.25g oleic acid, 30.44g propylene glycol, 0.43g p-toluenesulfonic acid to start stirring successively in the reactor that has thermometer, condensing tube, stirrer, and pass into nitrogen, Gradually raise the temperature to 80-120°C, and distill the water generated by the reaction at this temperature, and react for 3-6 hours. If no water is evaporated, stop the reaction, cool to room temperature and stand still. After the product settles and separates, you can get The upper layer product is exactly target product, and the esterification rate of fatty acid is 98.2%.

Embodiment 3

[0025] Synthesis of fatty acid monoester and fatty acid diester mixture: add 28.04g linoleic acid, 27.03g butanediol, 0.46g p-toluenesulfonic acid successively in the reactor with thermometer, condenser, stirrer to start stirring, and pass Enter nitrogen, gradually raise the temperature to 140-150°C, and distill the water generated by the reaction at this temperature, and react for 4-5 hours. If no water evaporates, stop the reaction, cool to room temperature and let it stand until the product settles and separates. Finally, the upper product obtained is the target product, and the esterification rate of fatty acid is 96.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| esterification rate | aaaaa | aaaaa |

| esterification rate | aaaaa | aaaaa |

| esterification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com