Soil conditioner produced from ardealite as well as producing method and using method of soil conditioner

A technology of soil improver and phosphogypsum, applied in chemical instruments and methods, land preparation methods, soil conditioning materials, etc., can solve problems such as limited market capacity of phosphogypsum comprehensive utilization products, and inability to produce phosphogypsum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

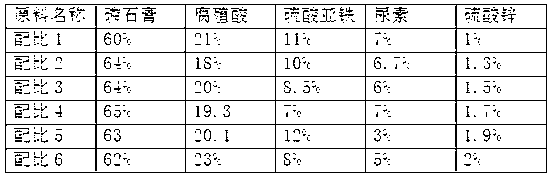

Embodiment 1

[0021] According to the weight percentage of ratio 1, prepare 100 tons of raw materials for production. After the materials are mixed evenly, they are sent to the granulator, and steam is introduced at the same time. The humidity is controlled at 15%-20%, and the temperature is 20°C-25°C. Hot air drying is carried out, the process temperature is controlled at 120°C-124°C, and the tail gas temperature is less than 60°C. The granular material is dried in the rotary dryer and then transferred to the flip cooler. After cooling to room temperature, it is screened in two stages. The first stage has a sieve hole of 4.75mm, and the large particles are screened out and crushed. The second-stage screening, the second-stage sieve hole is 2.2mm, and the materials with a particle size of less than 2.2mm are sent to the granulator together with the first-stage crushed materials, and the qualified materials after the second-stage screening are transferred to the coating film The system is co...

Embodiment 2

[0023] Prepare 100 tons of raw materials according to the weight percentage of proportioning 2 for production. The production process is the same as in Example 1, the only difference being the steam that passes into the granulator, the humidity is controlled at 16%-23%, the temperature is 25°C-30°C, and the temperature is 25°C-30°C. The air drying temperature is 122°C-128°C, and the amount of anti-caking agent used is 0.7% of the product weight.

Embodiment 3

[0025] Prepare 100 tons of raw materials according to the weight percentage of proportioning 2 for production. The production process is the same as in Example 1. The only difference is the steam that passes into the granulator, the humidity is controlled at 16%-25%, the temperature is 22°C-26°C, and the heat The air drying temperature is 125°C-130°C, and the amount of anti-caking agent used is 0.7% of the product weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com