Method for treating arsenic in water with high-specific-surface-area Schwertmannite adsorbent

A technology with high specific surface area and Shi's minerals, applied in the direction of adsorption water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve difficult large-scale industrial applications, difficult treatment, slow reaction kinetics process of oxidation method And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Weigh 30 mg of dry solid adsorbent into several Erlenmeyer flasks.

[0028] 2) Prepare the As(V) concentration of 20-550mg L respectively -1 0.1mol L -1 NaCl solution 30mL, containing As(III) concentration of 10-100mg L -1 0.1mol L -1 NaCl solution 30mL. Add each solution to the Erlenmeyer flask containing the adsorbent.

[0029] 3) Use 6mol L -1 HCl and 6mol L -1 NaOH solution accurately adjusts the pH of the suspension to 3.0 or 7.0.

[0030] 4) Shake the suspension in a water bath shaker, the temperature of the water bath is 25°C, and the shaker rotates at 140 rpm.

[0031] 5) After 3 hours, the suspension was separated by centrifugation, the speed of the centrifuge was 12000 rpm, and the concentration of arsenic in the solution was measured.

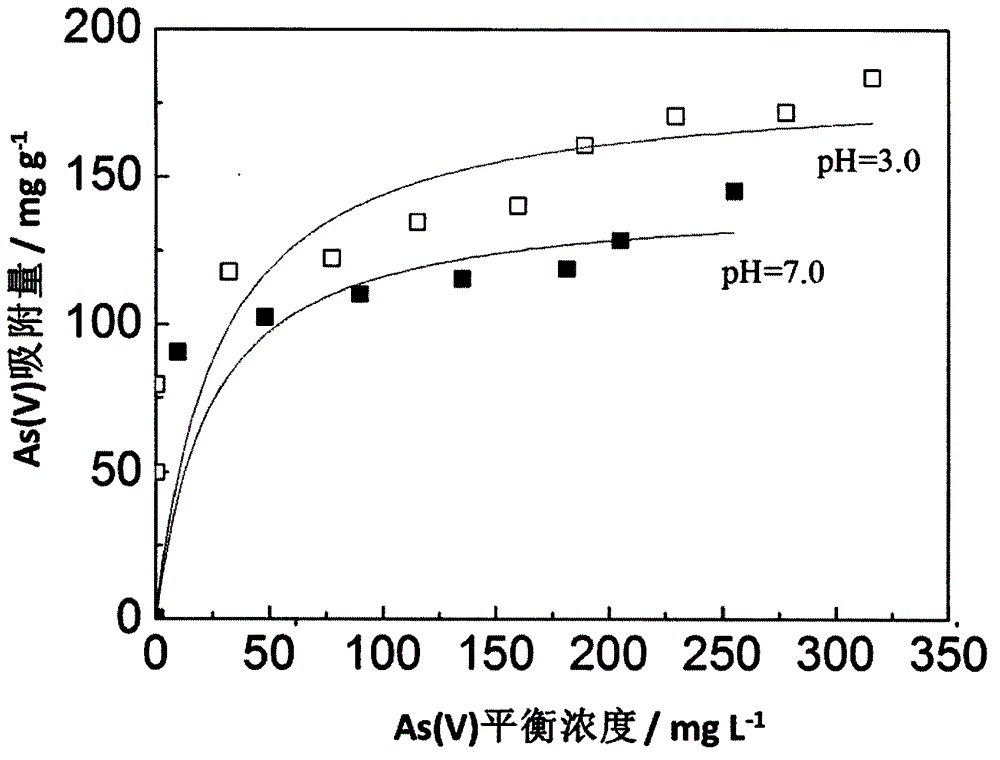

[0032] The implementation results show that: under the condition of pH 3.0, the adsorption capacity of the adsorbent to As(V) is 182.86 mg g -1 , the adsorption capacity for As(III) is 45.50 mg g -1 ; Under the c...

Embodiment 2

[0035] 1) Weigh 30 mg of dry solid adsorbent into several Erlenmeyer flasks.

[0036] 2) Prepare As(V) and As(III) concentrations of 100mg L respectively -1 0.1mol L -1 NaCl solution 30mL. Each solution was added to each Erlenmeyer flask which had been weighed with the adsorbent.

[0037] 3) Use 6mol L -1 HCl and 6mol L -1 NaOH solution adjusted the pH of each suspension containing As(V) and As(III) to 2.0, 3.0, 5.0, 7.0, 9.0 and 11.0, respectively.

[0038] 4) Shake the suspension in a water bath shaker, the temperature of the water bath is 25°C, and the shaker rotates at 140 rpm.

[0039] 5) After 3 hours, the suspension was separated by centrifugation, the speed of the centrifuge was 12000 rpm, and the concentration of arsenic in the solution was measured.

[0040] The results show that the low pH condition is favorable for the adsorption of As(V), and the high pH condition is favorable for the adsorption of As(III). For the adsorption of As(V), the adsorption amou...

Embodiment 3

[0042] 1) Weigh 30 mg of dry adsorbent solids into several Erlenmeyer flasks.

[0043] 2) Prepare As(V) and As(III) concentrations of 100mg L respectively -1 0.1mol L -1 NaCl solution 30mL. Each solution was added to each Erlenmeyer flask which had been weighed with the adsorbent.

[0044] 3) Use 6mol L -1 HCl and 6mol L -1 NaOH solution accurately adjusts the pH of the suspension to 3.0 or 7.0.

[0045] 4) Shake the suspension in a water bath shaker, the temperature of the water bath is 25°C, and the shaker rotates at 140 rpm.

[0046] 5) After 3 hours, the suspension was separated by centrifugation, the speed of the centrifuge was 12000 rpm, and the concentration of arsenic in the solution was measured.

[0047] 6) The separated solid is added again to the arsenic solution prepared according to step 2), and steps 3) to 5) are repeated.

[0048] The implementation results show that: under the condition of pH 3.0, the adsorption rate of As(V) by this adsorbent can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com