Working position apparatus in automobile production process

A technology of production technology and station equipment, applied in the direction of manufacturing tools, tool storage devices, etc., can solve the problems of low space utilization, rework of door outer panels, scratches, etc., so as to reduce the workload of rework, facilitate the operation of workers, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

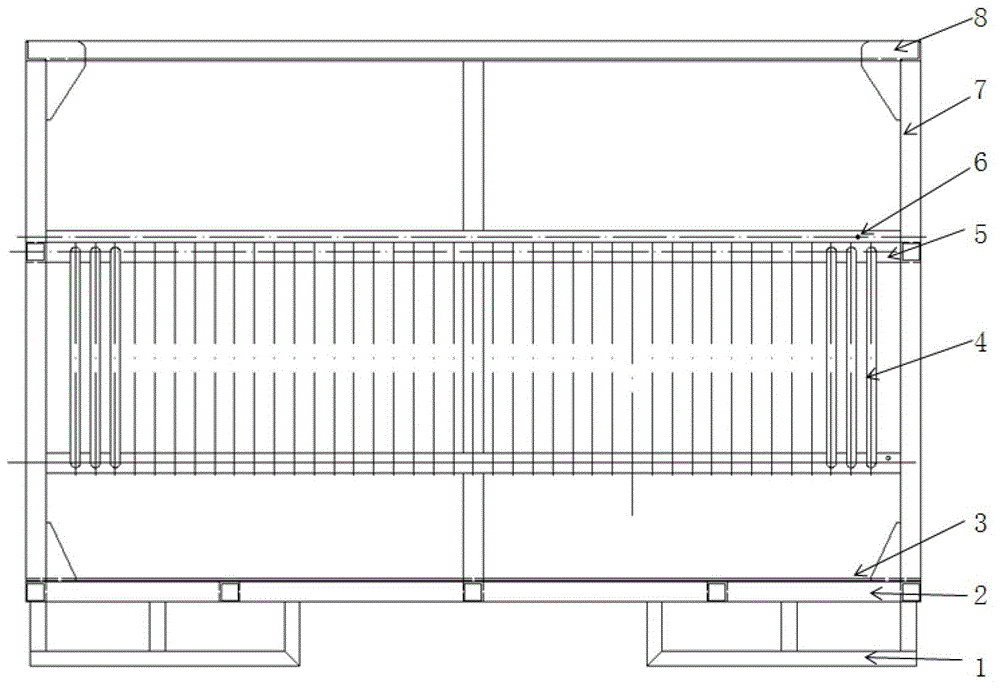

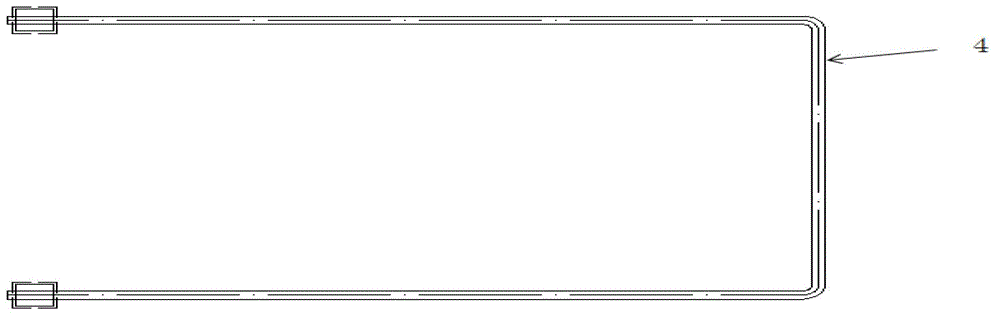

[0028] Such as Figure 1-2 , the technical solution provided by the present invention is, a kind of station equipment in automobile production process, comprises frame, and described framework is made of bottom frame 2, upright post 7 and angle steel 8, and described bottom frame 2, described upright post 7 and The angle steels 8 are connected sequentially, and the frame is provided with a protective device and a limiting device. The bottom end of the column 7 is connected to the bottom frame 2 , and the top end of the column 7 is connected to the angle steel 8 . The column 7 is welded or riveted with the bottom frame 2 , and the column 7 is welded or riveted with the angle steel 8 . The protective device is a U-shaped gear bar 4, and the gear bar is generally in the shape of a "U" with a transverse opening. The frame is also provided with a connecting rod 5, which is connected to the upright post 7 by welding, and the connecting rod 5 and the upright post 7 are vertically a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com