High-bioactivity ganoderma spore oil and supercritical preparation method thereof

A technology of Ganoderma lucidum spore oil and Ganoderma lucidum spore powder, which is applied in the direction of oil/fat refining, drug combination, and fat production, can solve the problems of failing to meet the requirements of freezing transparency experiments, affecting the appearance of products, etc., to avoid acidification and corruption, and reduce losses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

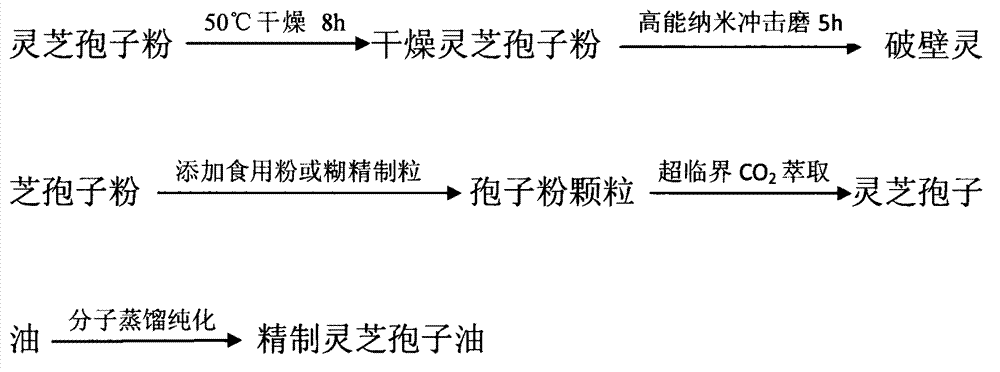

Method used

Image

Examples

Embodiment 1

[0027] Weigh 300g of Ganoderma lucidum spore powder, dry at 50°C for 8h, and then put it into a tank. According to the ball-to-material ratio of 2:1, the ratio of large beads to small beads is 1:1:1, and the treatment time is 5 hours. After completion, it is taken out, and the grinding medium is separated to obtain broken-wall spore powder. Mix the broken spore powder with 2% corn starch, put it into a dry press granulator to make 15-mesh granules, put it into a supercritical CO2 extraction kettle, put the absorbent cotton in the middle of the filter paper into the filter plate of the extraction kettle, The extraction pressure is 35MPa, the temperature is 40°C, and the extraction is 90min; add 20% absolute ethanol as an entrainer, and extract for 90min; the pressure of the separation tank I is 5.5MPa, and the temperature is 35°C; At 30°C, the extract was taken out from the separation kettle to obtain a light yellow oily liquid, and the entrainer was recovered by rotary evapora...

Embodiment 2

[0030] Weigh 400g of Ganoderma lucidum spore powder, dry at 50°C for 8h, and then put it into a tank. According to the ball-to-material ratio of 2.5:1, the ratio of large beads to small beads is 1:1:1, and the treatment time is 6 hours. After the treatment is completed, it is taken out, and the grinding medium is separated to obtain the broken spore powder. Mix the broken spore powder with 3% corn starch, put it into a dry press granulator to make 20-mesh granules, put it into a supercritical CO2 extraction kettle, put the absorbent cotton in the middle of the filter paper into the filter plate of the extraction kettle, Extraction pressure 30MPa, temperature 30°C, extraction 100min; add 25% absolute ethanol as entrainer, extraction 90min; separation tank I, pressure 5MPa, temperature 38°C; separation tank II pressure 6MPa, temperature 32°C , the extract was taken out from the separation tank to obtain a light yellow oily liquid, and the entrainer was recovered by rotary evapor...

Embodiment 3

[0033]Weigh 500g of Ganoderma lucidum spore powder, dry at 50°C for 10h, and then put it into a tank. According to the ball-to-material ratio of 3:1, the ratio of large beads to small beads is 1:1:1, and the treatment time is 7 hours. After completion, it is taken out, and the grinding medium is separated to obtain broken-wall spore powder. Mix the broken spore powder with 5% corn starch, put it into a dry press granulator to make 10-mesh granules, put it into a supercritical CO2 extraction kettle, put the absorbent cotton in the middle of the filter paper into the filter plate of the extraction kettle, Extraction pressure 38MPa, temperature 35°C, extraction 110min; then add 30% absolute ethanol as entrainer, extraction 60min; separation tank I, pressure 5MPa, temperature 40°C; separation tank II pressure 6MPa, temperature 35°C , the extract was taken out from the separation tank to obtain a light yellow oily liquid, and the entrainer was recovered by rotary evaporation. Put ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| peroxide value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com