Pickling salt and preparation method thereof

A kimchi and formula technology, applied in food preparation, application, food science, etc., can solve the problems of serious homogeneity, unhindered kimchi, single variety of kimchi salt, etc., and achieve high tea polyphenol content, less pollutants, and particles uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

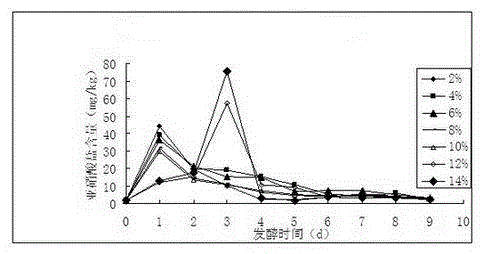

[0034] Embodiment 1 (study on optimum percentage of pickle brine)

[0035] A Prepare equal amounts of kimchi brine according to the salt concentration of 4%, 6%, 8%, 10%, 12%, and 14%.

[0036] B. Wash, drain, and evenly cut radish purchased from the market, and put equal amounts into salt water of different concentrations.

[0037] C Every 24 hours, according to the spectrophotometric method in GB 5009.33-2010, detect the content of nitrous acid in kimchi.

[0038] D determines that the optimal percentage of salt water for making pickles is 6-10% according to the nitrite content in pickles at different times (see figure 1 ).

Embodiment 2

[0039] Example 2 (Perilla optimal percentage research)

[0040] A Prepare 4 groups of equal amounts of kimchi brine of the same concentration (the optimum concentration of kimchi brine is known to be 6-10%), and mix 80-300 mesh perilla powder at the ratio of 0.02%, 0.04%, 0.06%, and 0.08%. (concentration in brine) were added to kimchi brine separately.

[0041] B. Wash, drain, and evenly cut radish purchased from the market, and put equal amounts into pickle brine.

[0042] C Every 24 hours, according to the spectrophotometric method in GB 5009.33-2010, detect the content of nitrous acid in kimchi.

[0043] D According to the nitrite content in kimchi at different times, the optimum percentage of perilla in brine is determined to be ≥0.04% (see figure 2 ).

Embodiment 3

[0044] Embodiment 3 (research on the optimum percentage of green tea powder)

[0045] A Prepare 4 groups of equal amounts of kimchi brine of the same concentration (the optimum concentration of kimchi brine is known to be 6-10%), and mix 80-300 mesh green tea powder in proportions of 0.01%, 0.03%, 0.05%, and 0.07% ( concentration in brine) were added to brine respectively.

[0046] B. Wash, drain, and evenly cut radish purchased from the market, and put equal amounts into pickle brine.

[0047] C Every 24 hours, according to the spectrophotometric method in GB 5009.33-2010, detect the content of nitrous acid in kimchi.

[0048] D According to the nitrite content in kimchi at different times, the optimum percentage of green tea powder in brine is determined to be ≥0.05% (see image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com