Degradable weeding film for tea leaf cutting nursery and application thereof

A technology of weeding film and cuttings, applied in the field of degradable weeding film, can solve the problems of airtightness, affecting plant growth and survival, etc., and achieve the effects of promoting healthy growth, improving survival rate, and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

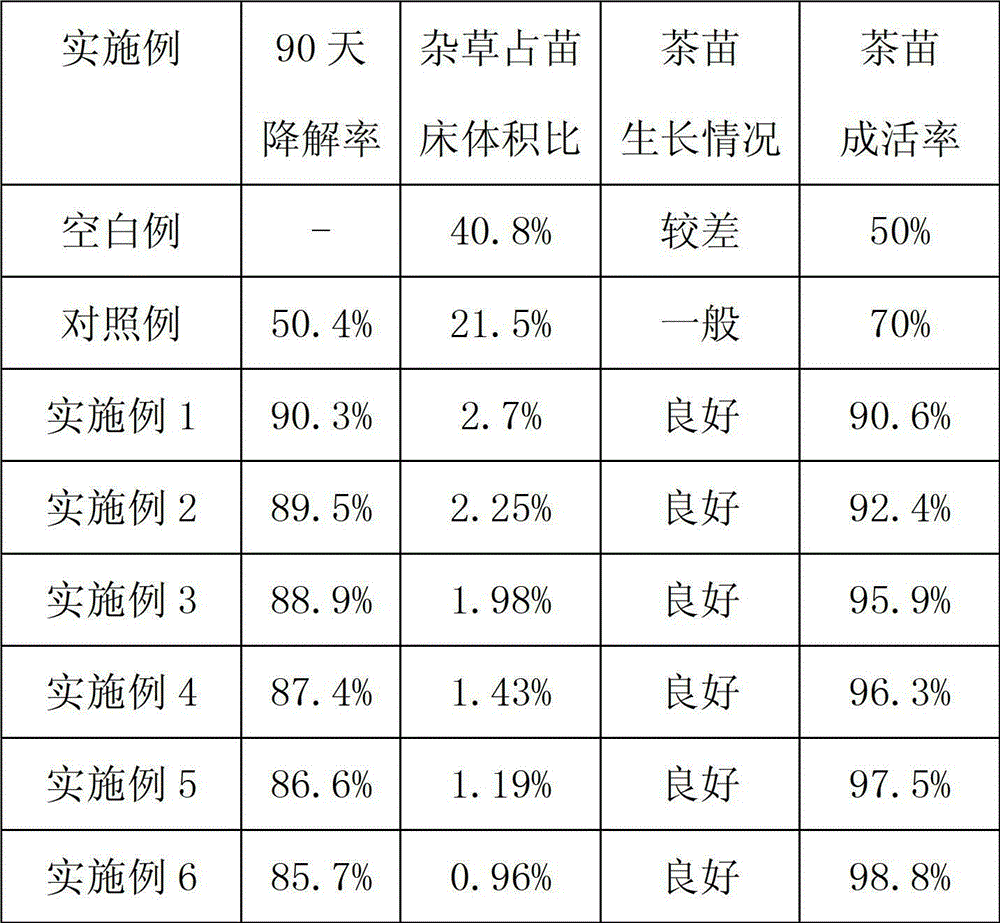

Examples

Embodiment 1

[0013] Cotton fiber and polypropylene fiber containing black masterbatch are compounded together by thermocompression bonding technology at a ratio of 0.8:1, with a thickness of 50g / m 2 , the shading rate is 85%.

Embodiment 2

[0015] Laminate ramie and flax fibers and polypropylene fibers containing black masterbatch in a ratio of 1:0.8 through thermocompression bonding technology, with a thickness of 52g / m 2 , the shading rate is 86%.

Embodiment 3

[0017] Combining the mulberry fiber and the polypropylene fiber containing the black masterbatch at a ratio of 0.8:1.2 by thermocompression bonding technology, the thickness is 54g / m 2 , the shading rate is 87%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shading coefficient | aaaaa | aaaaa |

| shading coefficient | aaaaa | aaaaa |

| shading coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com