Shift fork and method for producing same

A fork-like and fork-leg technology is applied in the field of shift forks manufactured according to this method, which can solve problems such as unloaded optimization and achieve the effect of saving axial structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

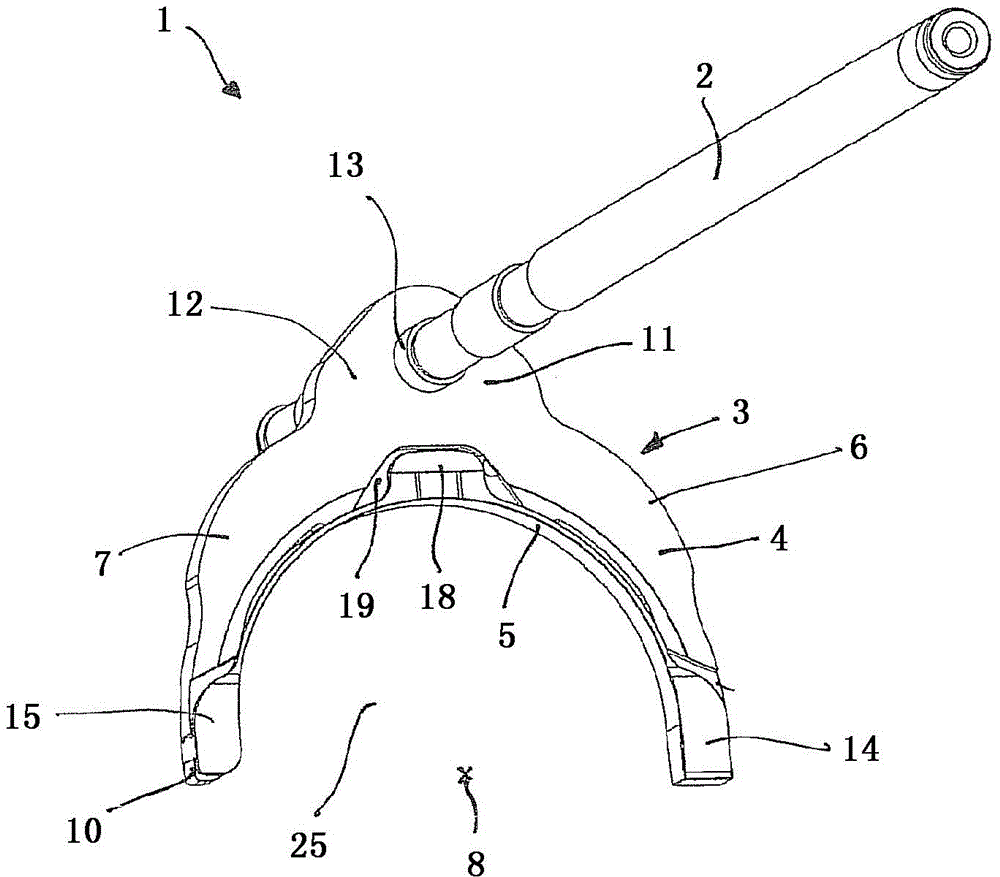

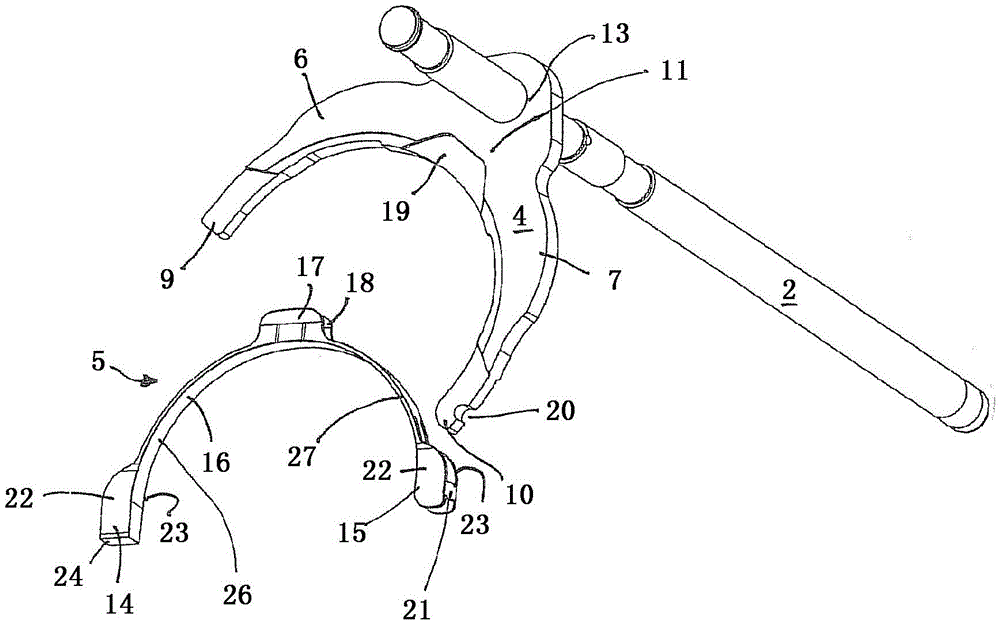

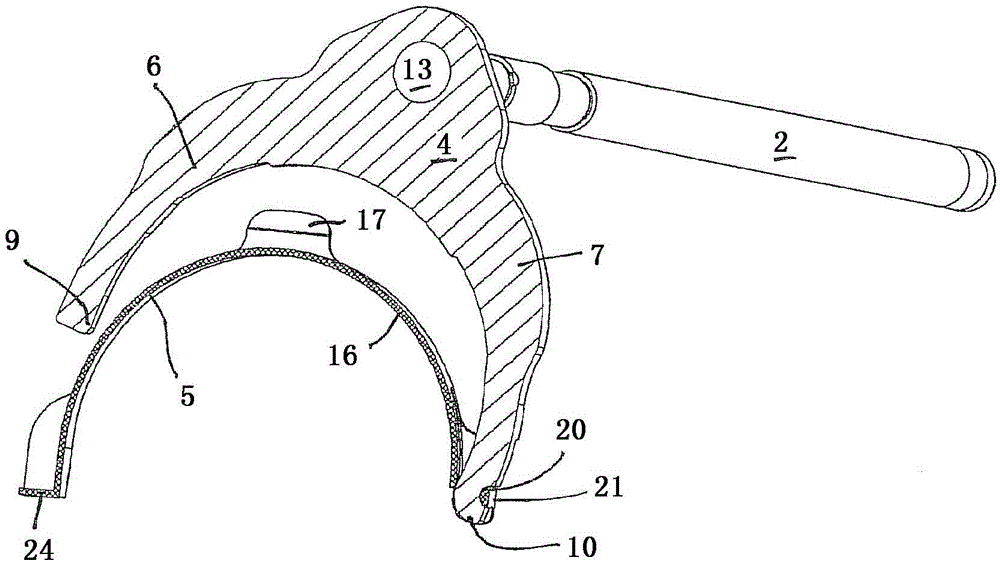

[0025] figure 1 Shown is a shifting unit 1 with at least a selector lever 2 and a shift fork 3 movable axially relative to a not-shown drive shaft. The shift fork 3 is firmly connected to the shift lever 2 so that movement of the shift lever 2 triggered by the operator or an actuator pushes the shift fork 3 axially for engaging or removing a gear by means of a shift bush not shown . The shift fork 3 has a body 4 and a sliding element 5 . The main body 4 is designed as an approximately semicircular stamped part made of sheet steel and has two fork legs 6 , 7 whose ends 9 , 10 are opposite relative to the drive axis 8 , that is to say offset from each other by approximately 180°. ground layout. The fork legs 6 , 7 narrow relatively towards their ends 9 , 10 as seen in cross section (relative to the transmission axis 8 ) and widen at the base 11 where the fork legs 6 , 7 are joined to each other in one piece . The connection of the selector lever 2 also takes place in the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com