Electric machine

一种定子、槽道的技术,应用在电力机车、机车、机动车等方向,能够解决增加所需空间、高压力降、灰尘积聚等问题,达到低重量水平、低产品成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

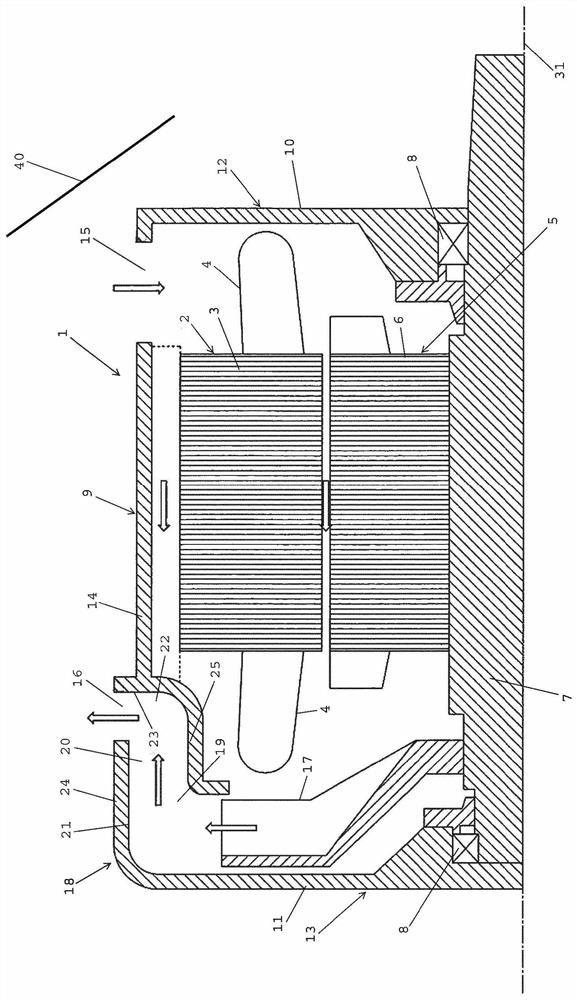

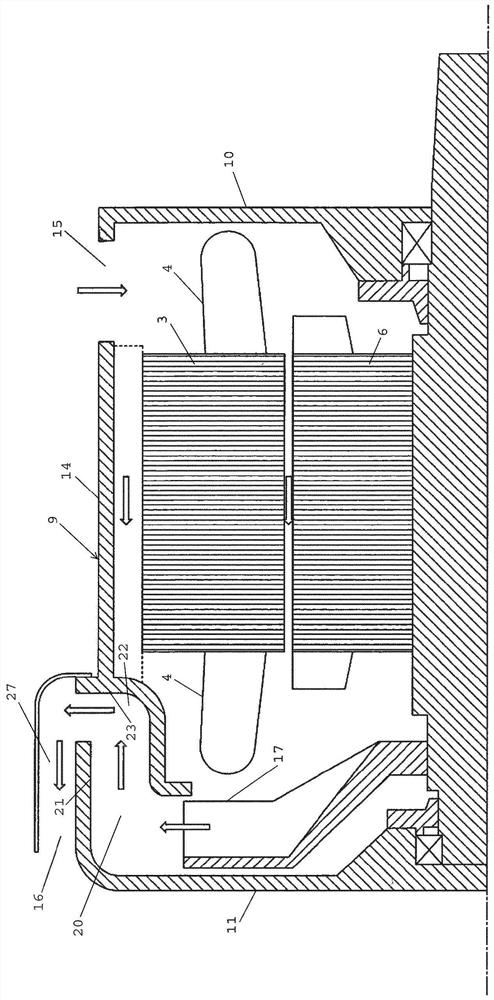

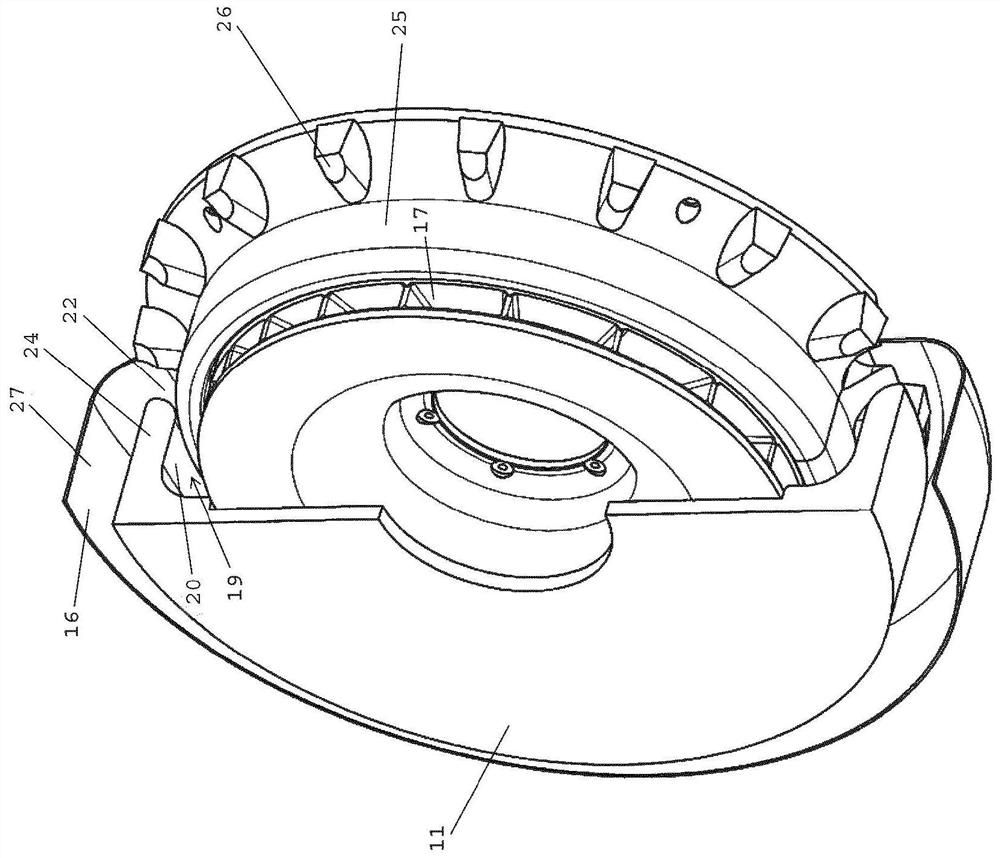

[0029] figure 1 An electric machine 1 according to a first embodiment of the invention is very schematically represented. It means that the motor is arranged in a rail vehicle 40, and the motor has a stator 2, the stator 2 has a stator body 3, the stator body 3 has a stator winding 4, and the stator winding 4 is arranged to generate electricity around the stator body A plurality of stator poles arranged around the inner periphery. The rotor 5 is arranged rotatably about a rotor axis 31 in the stator and has a rotor body 6 . The rotor may be provided with permanent magnets or any other type of components, such as conductive rings, for electromagnetic inductive interaction with the stator windings. The figure shows how the rotor is fixed on the rotor shaft 7 in the form of a rod received in a bearing 8 .

[0030] The electric machine has a housing 9 enclosing a rotor 5 and a stator body 3 with stator windings 4, and the casing comprises end shields 10, 11 arranged at respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com