Internal combustion engine with multi-joint crank drive and additional mass on the articulated linkage of the multi-joint crank drive for damping free inertial forces

A technology of articulated connecting rod and crank transmission, which is applied in the direction of inertial force compensation, engine control, machine/engine, etc., can solve the problem of enlargement, and achieve the effect of improving structural space and weight increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

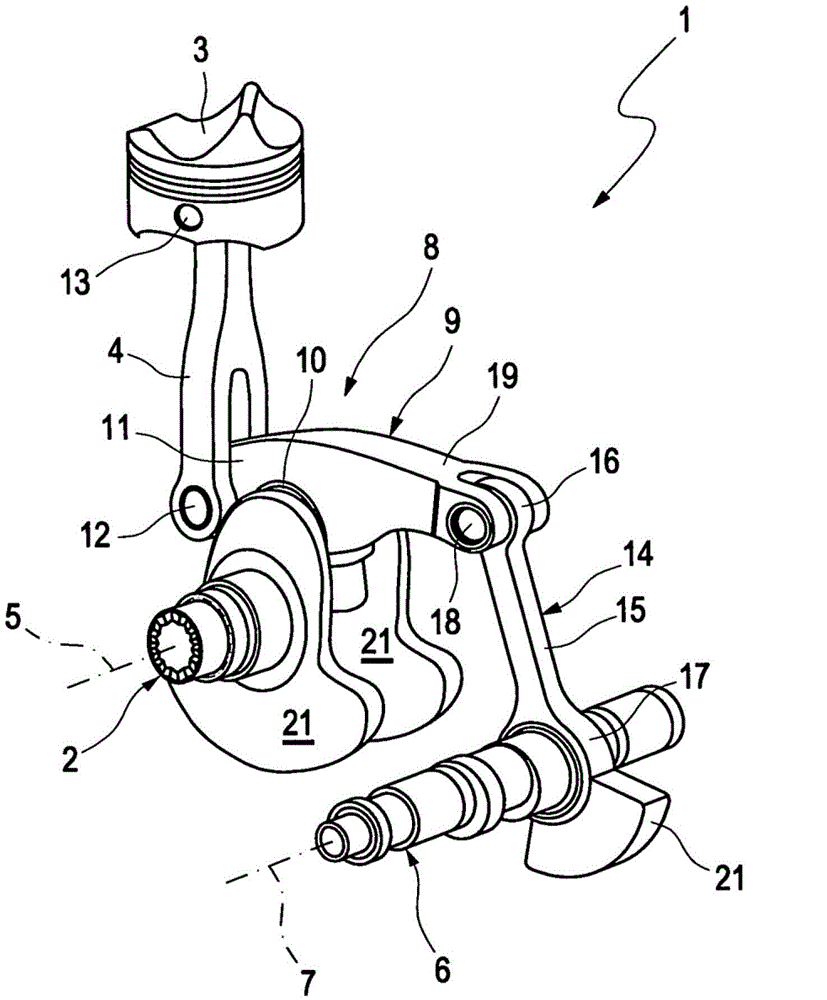

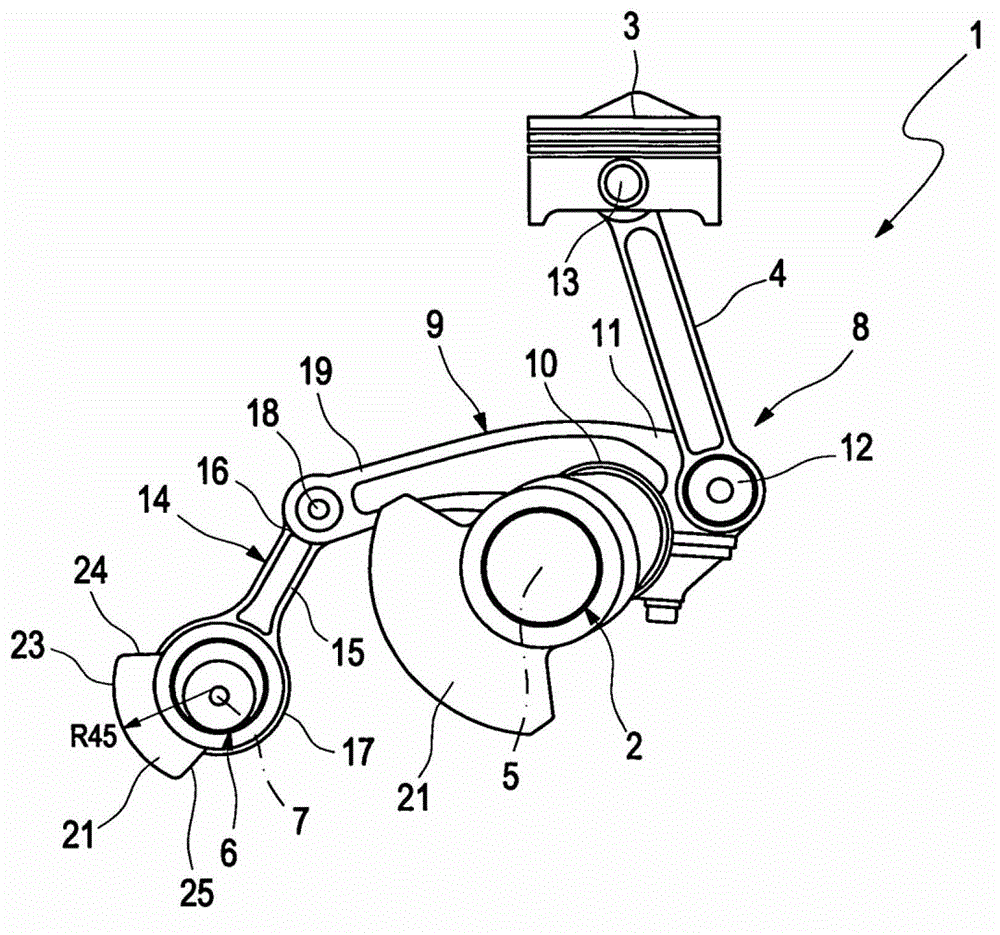

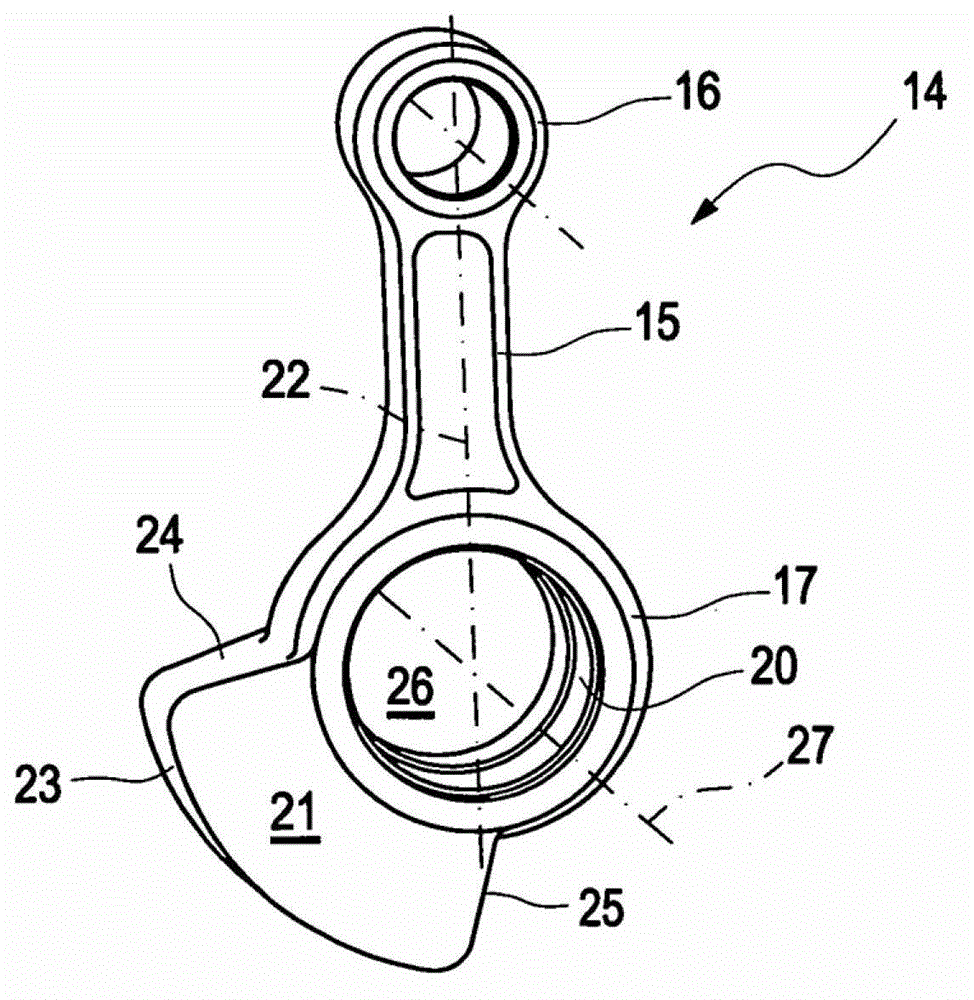

[0026] Such as figure 1 with figure 2 as well as Figure 4 with Figure 5 As most clearly shown in , the four-stroke 4-cylinder internal combustion engine 1 , which is only partly shown in the drawings, comprises a crankshaft 2 and four pistons 3 in a series arrangement, only the four pistons 3 being shown respectively in the drawings. One of the pistons. Piston 3 can reciprocate in a cylinder (not shown) of internal combustion engine 1 and is connected with crankshaft 2 via piston connecting rod 4 . The crankshaft 2 is mounted rotatably about an axis of rotation 5 in a cylinder crankcase (not shown) of the internal combustion engine 1 .

[0027] The internal combustion engine 1 also includes an eccentric shaft 6 with an axis of rotation 7 parallel to the axis of rotation 5 of the crankshaft 2 , which is rotatably mounted in the cylinder crankcase next to and approximately below the crankshaft 2 and passes through The multi-hinge crank transmission mechanism 8 is coupled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com