Framework for optical fiber gyroscope and manufacturing method thereof as well as method for packaging optical fiber ring

A technology of fiber optic gyroscope and fiber optic ring, which is applied in the field of packaging fiber optic rings, can solve the problems of phase noise generated by optical receiving devices, achieve the effects of reducing sound pressure interference, avoiding heat flow direction, and eliminating stress and size effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further described as follows in conjunction with accompanying drawing and example:

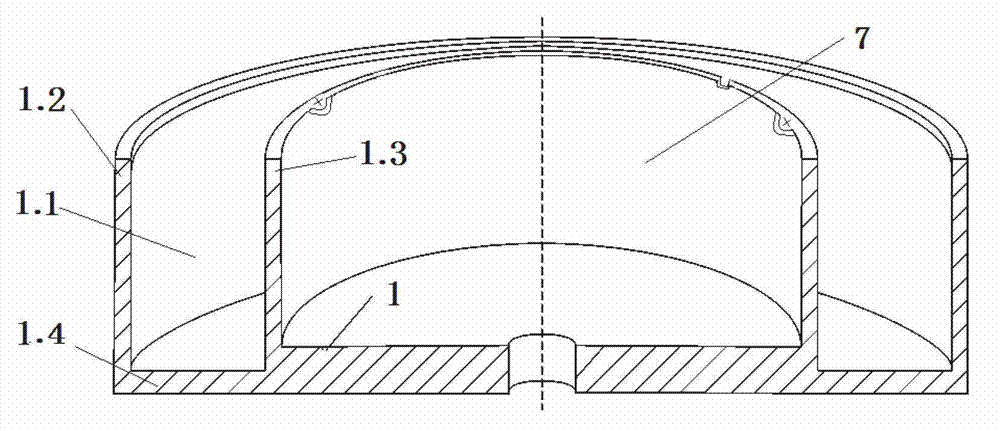

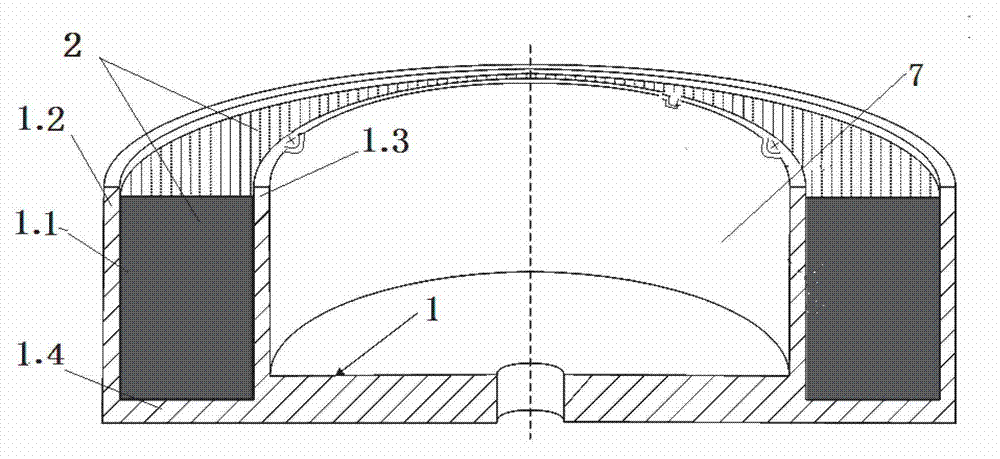

[0026] Such as figure 2 Shown in -7 is an embodiment of the skeleton for the fiber optic gyroscope of the present invention, which is a skeleton for the fiber optic gyroscope capable of heat and vibration isolation, including a skeleton body 1 composed of an outer wall 1.2, an inner wall 1.3 and a groove bottom 1.4; The annular groove 1.1 formed by the outer wall 1.2, the inner wall 1.3 and the groove bottom 1.4 is an open cavity for installing the optical fiber ring 6; the inner surface and the bottom surface of the annular groove 1.1 have a flame-retardant, heat-insulating and vibration-isolating material layer 2. There is an adhesive layer 3 on the thermal insulation and vibration isolation material layer 2; there is also a lower anti-vibration gasket 4.1 on the adhesive layer 3 on the bottom of the groove 1.4; the upper opening of the annular groove 1.1 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com