Two-stage centrifugal turbine pump

A water-wheel pump and water-wheel technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of limited driving force, limited lift of the water-wheel pump, unsuitable water-wheel pump, etc. Convenience and wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

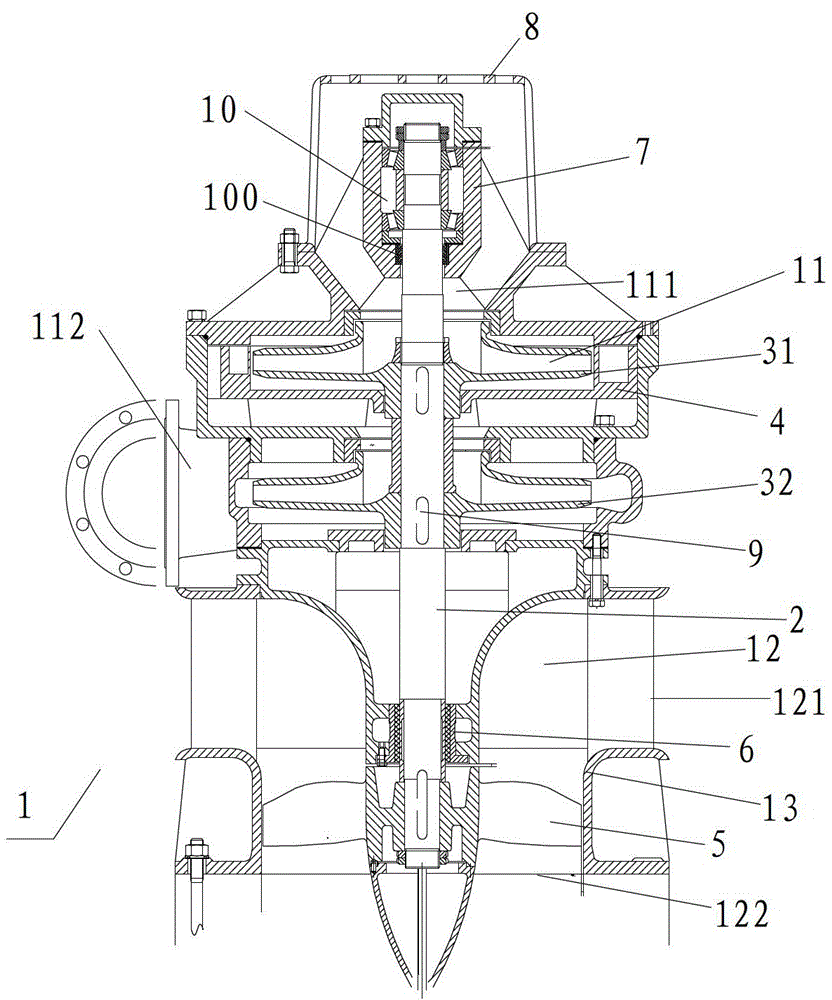

[0017] see figure 1 , this embodiment provides a two-stage centrifugal water wheel pump, including a pump body 1 and a pump shaft 2 rotatably arranged in the pump body 1, the pump body 1 includes a water wheel chamber 11 and a pump chamber 12, the The water wheel chamber 11 is located above the pump chamber 12, and the pump shaft 2 is divided into a first section shaft located in the water wheel chamber 11 and a second section shaft located in the pump chamber 12; two same shafts are fixed on the first section shaft. To the impeller (first-stage impeller 31, second-stage impeller 32), the inner wall of the corresponding impeller (first-stage impeller 31) of the water wheel cavity 11 is provided with guide vanes 4, and the guide vanes 4 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com