Synthetic resin wave-shaped waterproof board, application thereof and roof waterproof structure

A synthetic resin and waterproof structure technology, applied in the field of composite building materials, can solve the problems of long construction period and achieve the effects of saving engineering cost, high strength and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

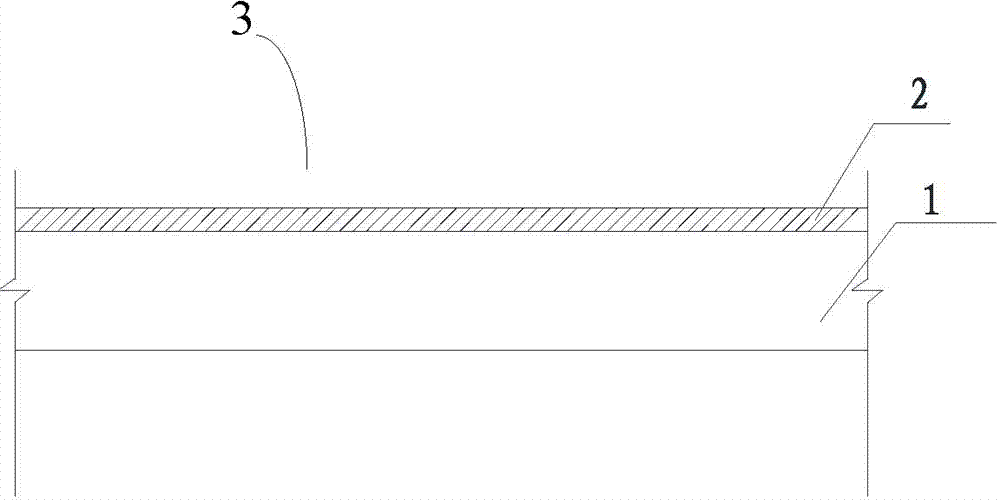

[0015] As shown in Fig. 1, it is a synthetic resin corrugated waterproof board 3 of the present invention, which is composed of a surface layer 1 and a base layer 2. The material of the surface layer 1 and the base layer 2 are polyvinyl chloride (PVC) or other thermoplastics. The surface layer 1 and the base layer 2 are co-extruded, and then passed through a molding machine at the same time to make various wavy shapes.

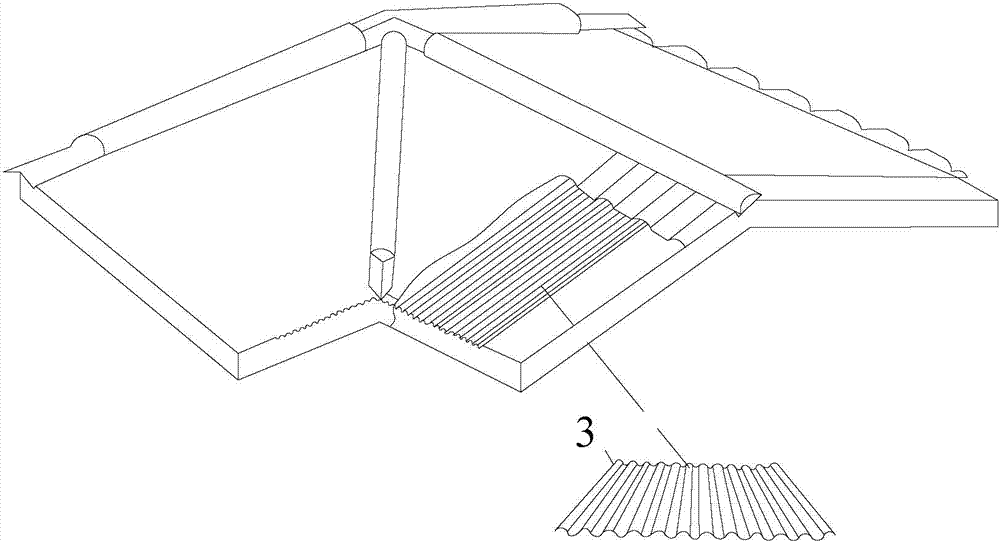

[0016] As shown in Figure 2, it is a structural schematic diagram of the synthetic resin corrugated waterproof board 3 used in the roof structure of the present invention, mainly used in the waterproof and ventilated board of the roof structure, and the roof structure with the purpose of the present invention includes a bottom-up concrete base, an insulation layer , Synthetic resin corrugated waterproof boards, tiles and roof tiles.

[0017] As a waterproof and ventilated panel, the synthetic resin corrugated waterproof board has the characteristics of dense m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com