A special positioning fixture for assembling sapphire crystal rods

A technology for positioning fixtures and sapphire, applied in crystal growth, post-processing details, post-processing and other directions, can solve problems such as low bonding efficiency, unfavorable processing, crystal rod swing, etc., to improve efficiency, shorten processing time, and reduce removal amount Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

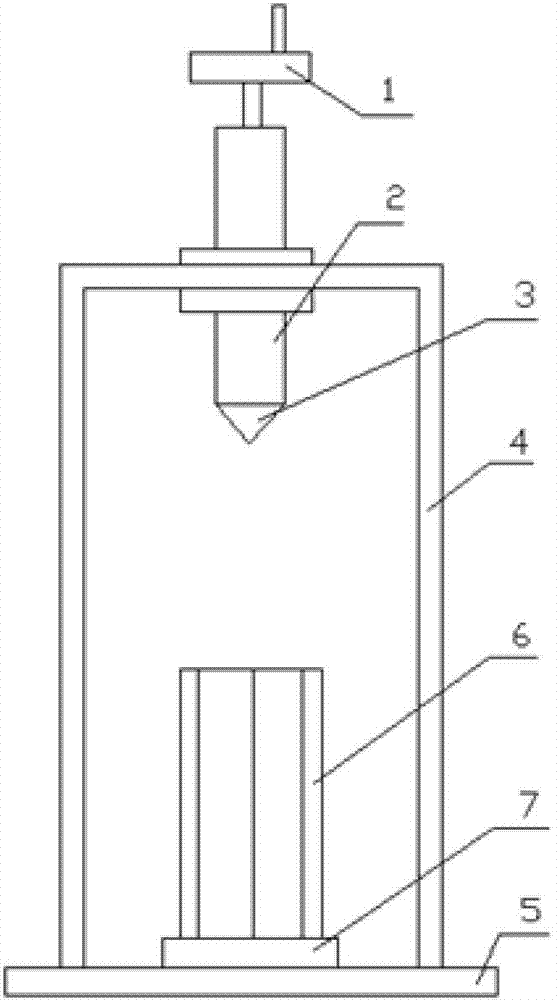

[0018] combine Figure 1-Figure 3 , present embodiment comprises platform 5 and the support 4 that is fixed on the platform, and screw mandrel 2 is installed on the support 4, and the upper end of screw mandrel 2 is fixed with the handle 1 that is used for adjusting screw mandrel 2 to move up and down, and its bottom is fixed with thread Mid-position top 3.

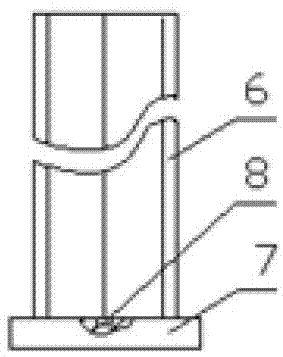

[0019] The crystal outer circle radial positioning body 6 and the axial positioning base 7 are positioned and connected through corresponding positioning pins and positioning holes. There is a positioning hole 8 on the upper end surface of the axial positioning base 7 for placing the end of the centering disc. Its diameter is 5-30 mm, and its depth is 10-30 mm.

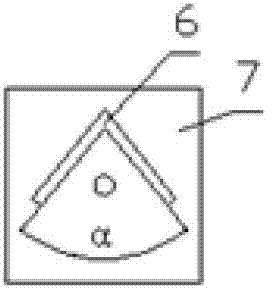

[0020] The crystal outer circle radial positioning body 6 and the axial positioning base 7 corresponding to the outer circle diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com