Modified polyphenyl thioether composition and LED (light-emitting diode) display screen back cover prepared therefrom

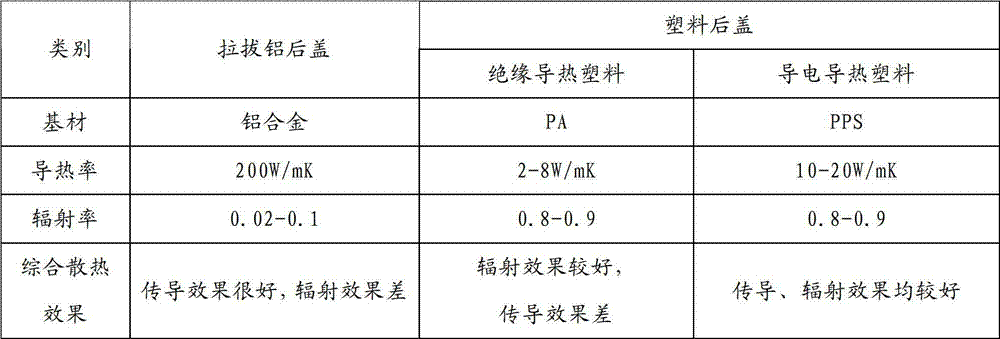

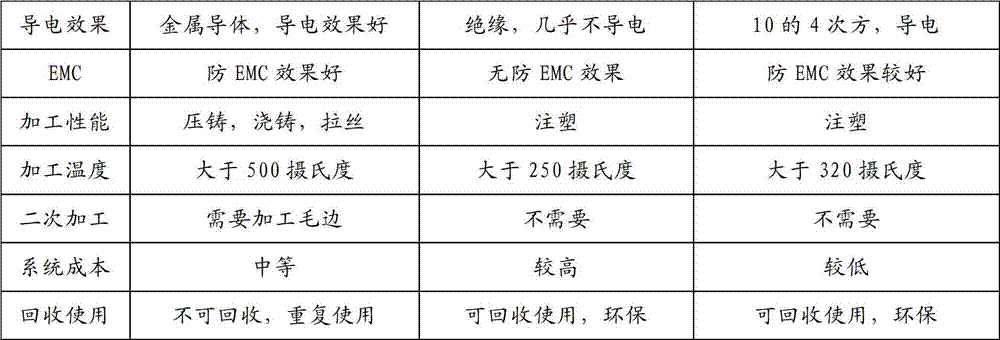

A technology of LED display and polyphenylene sulfide, which is applied in the direction of chassis/cabinet/drawer parts, etc., can solve the problem of not guaranteeing the heat dissipation effect, etc., and achieves long service life, good thermal conductivity, and high thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A modified polyphenylene sulfide composition provided in this specific embodiment includes: polyphenylene sulfide (PPS), carbon fibers and processing aids, wherein the weight percentage content of carbon fibers is 75%, and the weight percentage content of processing aids 5%. And the processing aid contains 4% of compatibilizer, 0.6% of lubricant and 0.4% of antioxidant. This is the optimal ratio determined through many experiments. In fact, the weight percentage content of carbon fiber is 70-80%, and the weight percentage content of processing aid is 2-10%, which can achieve good results; when the weight percentage content of carbon fiber is 72-78%, the weight percentage content of processing aid When the percentage content is 2-8%, better effect can be achieved.

[0020] A modified polyphenylene sulfide composition provided in this specific embodiment is prepared by adding conductive carbon fibers to high-performance engineering plastic substrate polyphenylene sulfid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com