Pollution abatement method for livestock and poultry farm

A technology for pollution control and farms, which is applied in the field of zero pollution, zero discharge of large-scale livestock and poultry farms, resource management, and pollution treatment of large-scale livestock and poultry farms. Huge area, low efficiency and other problems, to achieve the effect of resource utilization, small footprint and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

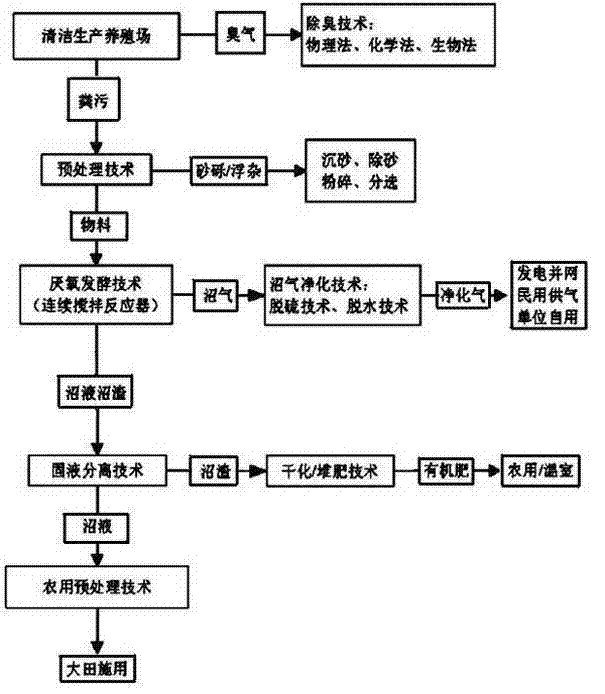

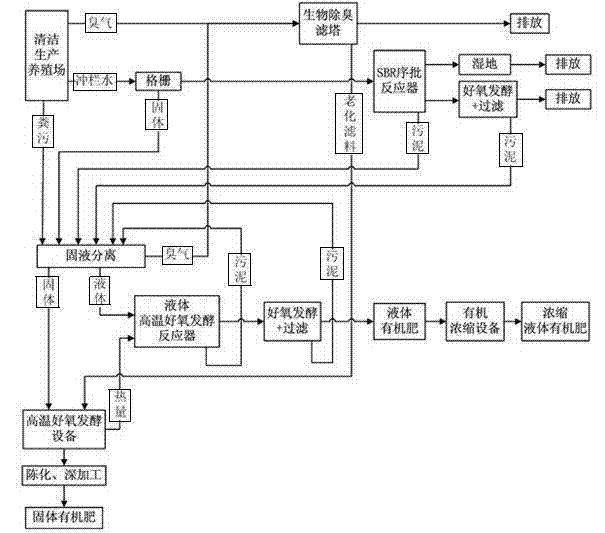

[0038] According to the attached image 3 The first embodiment of the present invention will be described. In the first embodiment, a plug-flow anaerobic fermentation reactor is used as the liquid bioreactor.

[0039] 1. Install slatted floor, manure removal device or / and dry manure removal process in the pig house of large-scale pig farm to separate manure (including manure + urine) from flushing water at the source, so that it can be separated To process.

[0040] 2. The manure and sludge produced in the livestock and poultry farms and the sludge produced in each treatment process are separated from the solid-liquid by a screw extrusion solid-liquid separator. The solid part obtained from the solid-liquid separation should have an optimized water content of: 50 % <Water content <60%.

[0041] 3. The liquid part produced by solid-liquid separation is sent to a plug-flow anaerobic fermentation reactor for anaerobic fermentation. The plug-flow anaerobic fermentation reactor is a plug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com