Leakage block

A technology for liquid leakage and liquid leakage holes, which is applied to the sealing of engines, vehicle parts, sealing devices, etc., can solve the problems of vehicle noise, vibration and insufficient performance of sound and vibration roughness, and achieve convenient assembly and disassembly operations, convenient replacement, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further explained below according to the drawings and specific embodiments.

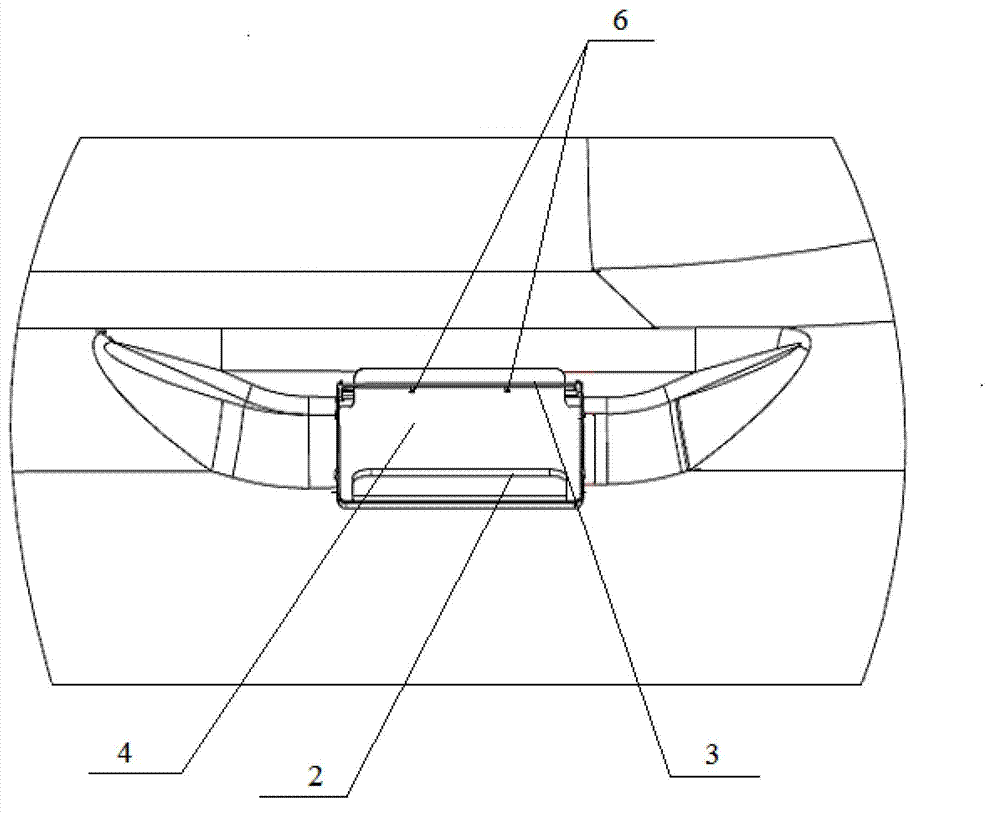

[0022] The overall design principle of the leakage blockage of the automobile door is to design according to the actual conditions of the leakage hole and the structure of the inner panel of the vehicle door. In this preferred embodiment, carry out the design of leakage plugging of the present invention according to the leakage hole of square automobile door. figure 1 Shown is a structural schematic diagram of the leakage and blockage of the automobile door in the embodiment of the present invention. from figure 1 It can be seen from the figure that the liquid leakage blockage includes a fixed structure 1 , a blockage baffle plate 2 , a suspension structure 3 , a blockage pad 4 and a clamping structure 5 .

[0023] Fixing structure 1 is the plugging fitting surface. Here, the blocking fitting surface is designed as two curved surfaces a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com