Injection mold

A technology for injection molds and mold cores, which is applied in the field of injection molds to achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

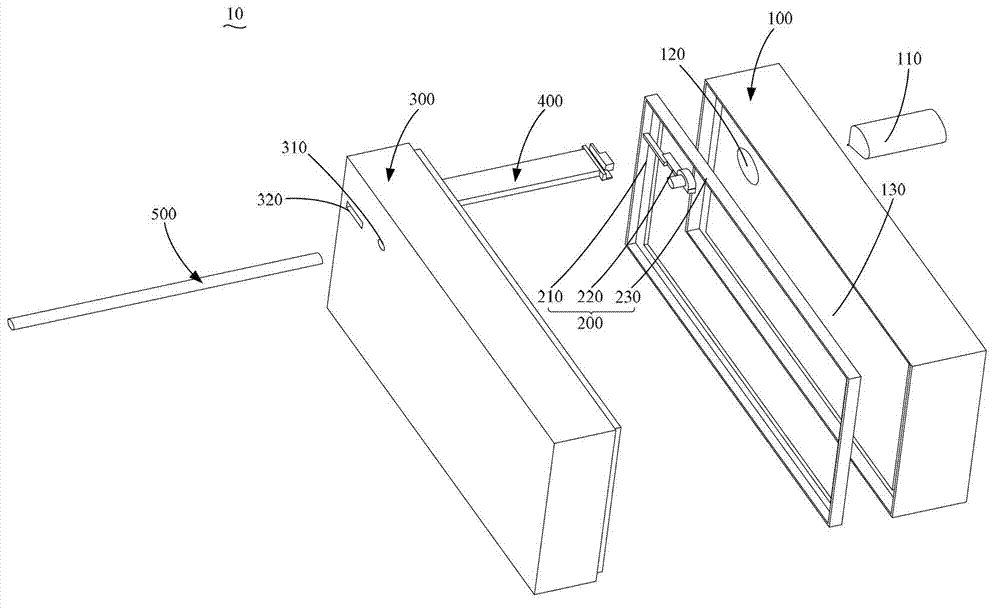

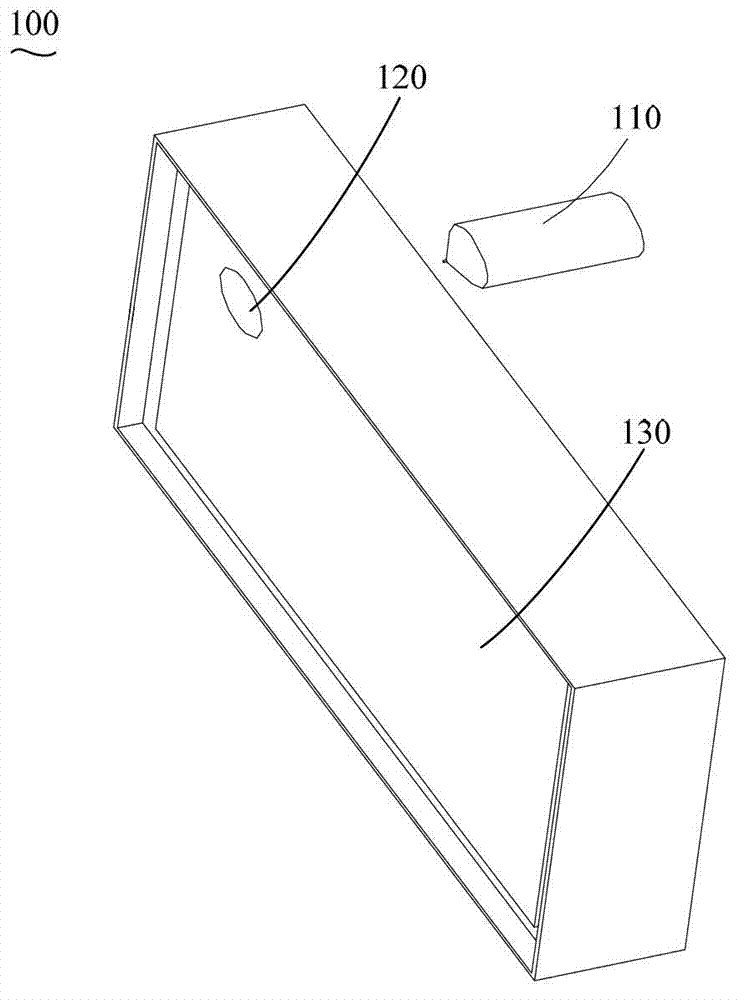

[0024] Please refer to figure 1 and image 3 , figure 1 It is a schematic diagram of the decomposition structure of a preferred embodiment of the injection mold of the present invention, image 3 for figure 1 Schematic diagram of the structure of the rear mold core of the injection mold shown. The injection mold 10 of the preferred embodiment of the present invention comprises a front mold core 100, a rear mold core 300 matched with the front mold core 100, and an ejection mechanism matched with the rear mold core 300, and the ejection mechanism includes The ejector pin 400 and the ejector pin 500, the front mold core 100 and the rear mold core 300 cooperate with each other to form a mold cavity. The rear mold core 300 is provided with a first groove 340, and the ejector pin 400 is inserted into the first groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com