Automatic welding device for vehicle body-in-white

An automatic welding, body-in-white technology, applied in welding equipment, resistance welding equipment, electrode features, etc., can solve the problems of unfavorable promotion, high initial investment and maintenance costs, and achieve compact and simple structure, high quality consistency, and low investment and maintenance costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

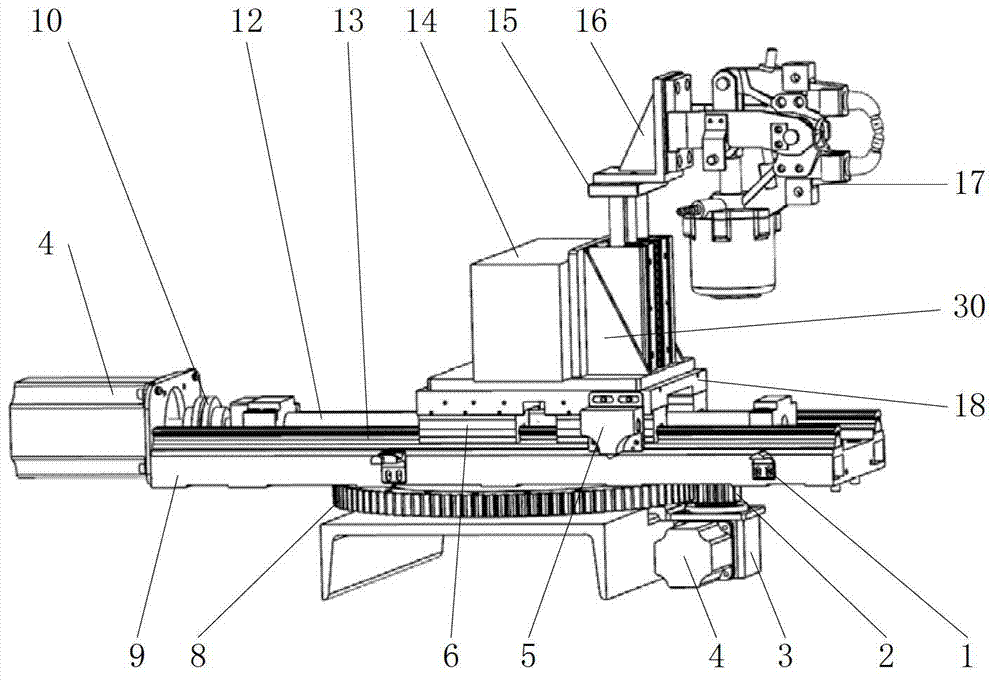

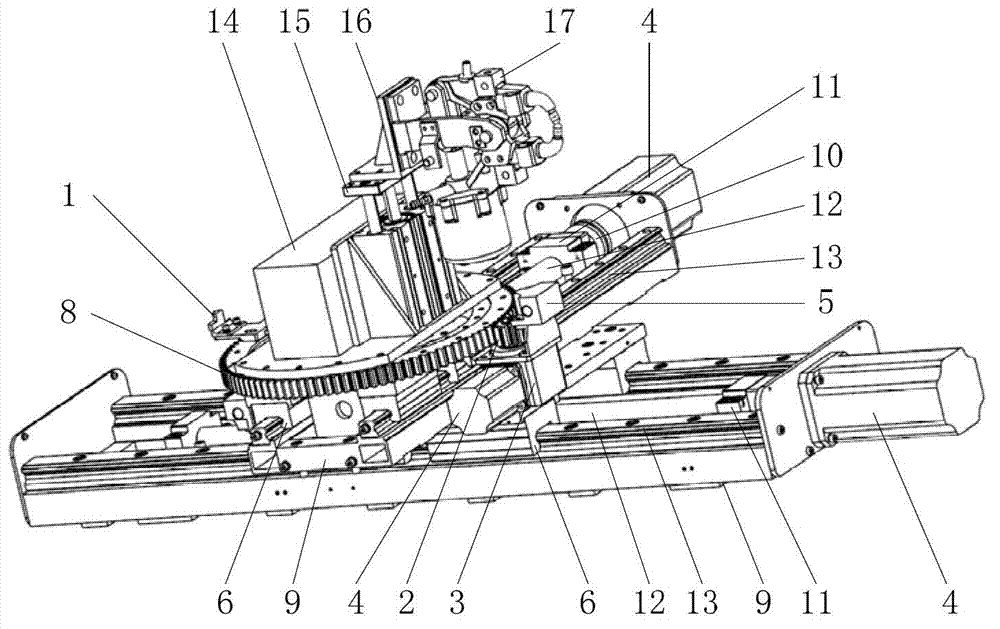

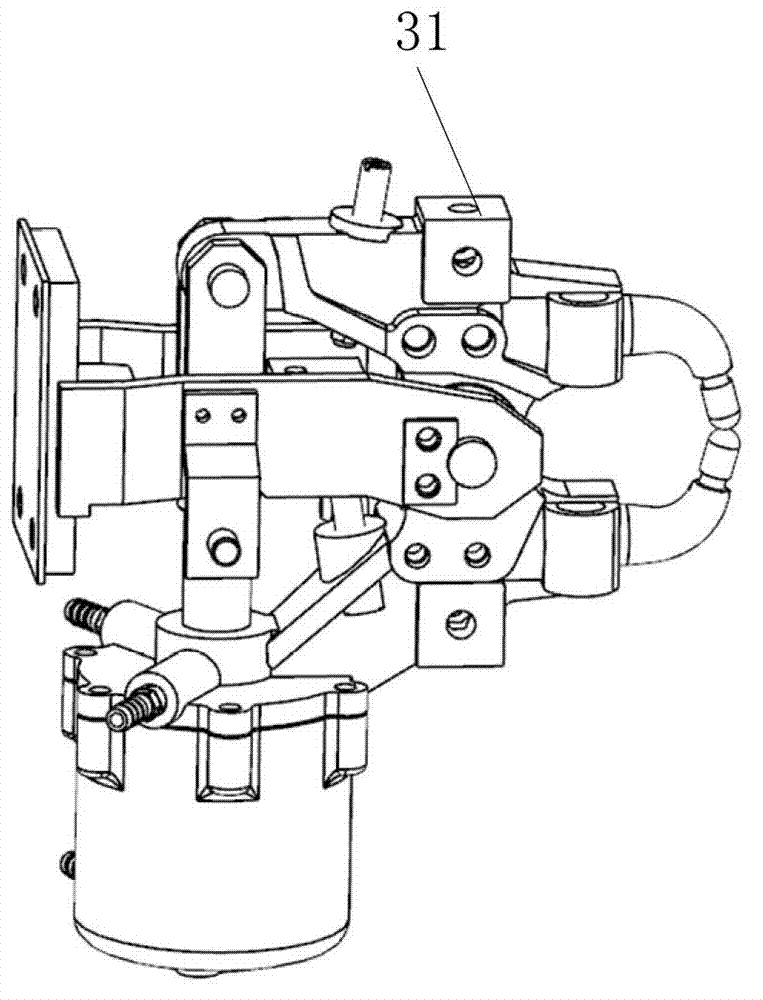

[0013] Such as figure 1 As shown, the Z-axis load module with welding tongs 17 is connected to the multi-axis linear module, and the rotation module converts the rotation of the motor 4 into rotary motion. In the multi-axis linear module, the motor 4 is connected to the ball screw 12 through the coupling 10 The nut on the screw rod is connected with the slider 6 on the linear guide rail 13 for guiding through the working plate 18, and the screw rod 12 is driven to rotate by the rotation of the motor 4, so that the nut on the screw rod 12 can be rotated along the screw rod 12. Then the nut pushes the table plate 18 and the slider 6 to move linearly along the linear guide rail 13, and finally realizes turning the rotary motion of the motor 4 into a linear motion along the linear guide rail 13, through the combination of rotary motion and linear motion Realize the welding of three-dimensional solder joints within the mechanical stroke, wherein the multi-axis linear module include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com