High-pressure pulsed turbulent flow pipeline flushing system

A pipeline flushing and high-pressure pulse technology, which is applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, cleaning hollow objects, etc., can solve the problem of unsatisfactory pipeline flushing in the hydraulic system, shorten the cleaning time, and improve the flushing efficiency. Efficiency, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

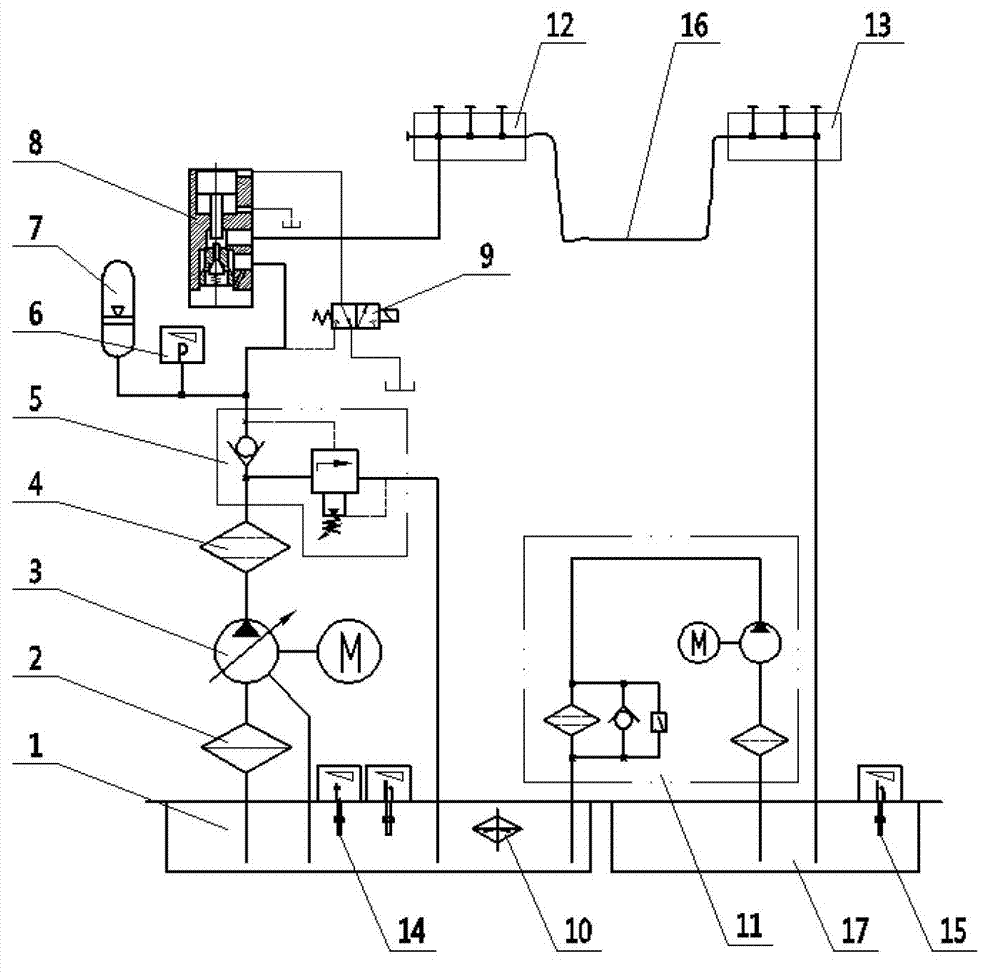

[0024] The figure shows a high-pressure pulse turbulent pipeline flushing system, which is characterized in that the system includes a main oil tank 1 and an auxiliary oil tank 17, the main oil tank 1 is provided with a heater 10, the main oil tank 1 and the auxiliary oil tank 17 The oil pump motor group 3, the pressure sensor 6, the hydraulic control check valve 8 and the flushed pipeline 16 are connected in sequence; the other end of the oil pump motor group 3 is connected to the main oil tank 1, and both ends of the hydraulic control check valve 8 A solenoid valve 9 for controlling the opening and closing of the hydraulic control check valve 8 is provided, a temperature sensor 14 is also provided on the main oil tank 1, and a filter pump set 11 is also connected to the main oil tank 1 and the auxiliary oil tank 17 between them.

[0025] An unloading overflow valve 5 is also provided between the oil pump motor group 3 and the pressure sensor 6, and the other end of the unloading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com