Asymmetric bipyramid mixer for quantitative liquid spray

An asymmetric, mixer technology, used in mixers, mixers with rotating containers, mixer accessories, etc., can solve the problems of easy dead corners, difficult to mix evenly, and sticking of rotating blade liquid medicine, etc. The effect of improving curing time and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

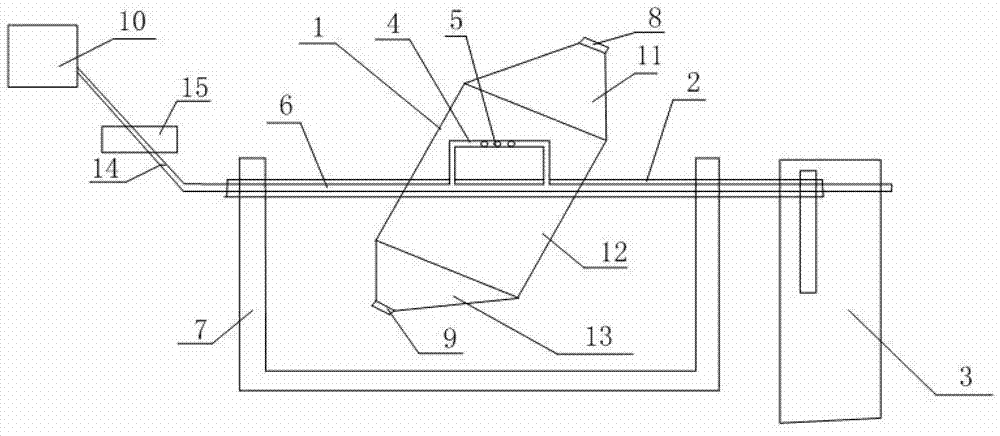

[0028] Such as figure 1 As shown, the asymmetric double-cone quantitative jet liquid mixer includes a cylinder body 1, a main rotating shaft 2 connected to the cylinder body, and a power device 3 for driving the main rotating shaft 2 to rotate.

[0029] This embodiment also includes a support frame 7 on which both ends of the main rotating shaft are arranged. When the power unit 3 is in operation, it drives the main rotating shaft on the support frame 7 to rotate, thereby driving the cylinder 1 to rotate.

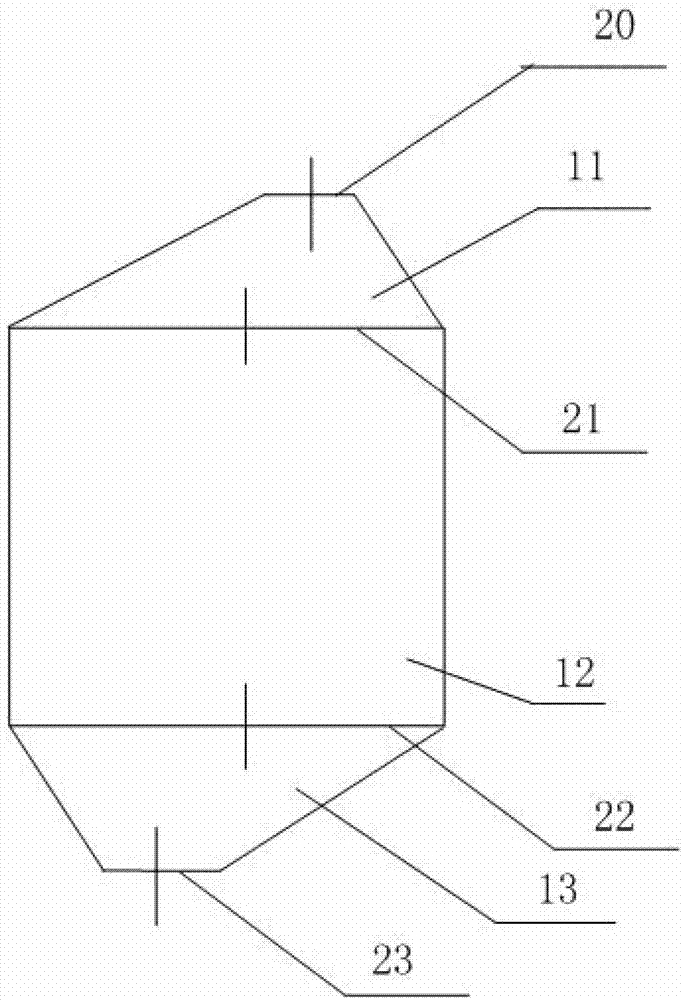

[0030] Such as figure 2 As shown, in this embodiment, the cylinder body 1 is a cavity composed of an upper cone 11 , a main body 12 , and a lower cone 13 that are connected sequentially from top to bottom and communicated internally as a whole. The top of the upper cone 11 is provided with an inlet 8 , and the bottom of the lower cone 13 is provided with an outlet 9 . Wherein, the lower bottom surface 21 of the upper cone is in contact with the upper bottom surface of t...

Embodiment 2

[0035] The present embodiment is basically the same as Embodiment 1, and its difference is only: the radius of the upper bottom surface 20 of the upper cone is defined as R1, the body cylinder (i.e. the radius of the lower bottom surface 21 of the upper cone, that is, the radius of the lower cone) The radius of the upper bottom surface 22) is defined as R2, and the radius of the lower bottom surface 23 of the lower cone is R3. The length relationship of R1, R2 and R3 satisfies the following condition: R1=R3=1 / 6R2. When R1=R3=1 / 6R2, the inventor has found through many tests that when R1=R3=1 / 6R2, the mixing effect of EVA pellets and liquid medicine is the best after the equipment is in operation. It can greatly shorten the curing time of EVA film and reduce its curing temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com