Extraction method of longan seed polyphenol

An extraction method and longan core technology are applied in the field of extracting longan core polyphenols from waste longan core in the longan processing industry, which can solve the problems of equipment investment, high production cost, staying in scale, and many impurity components, and achieves low production cost, Reduced potential toxicity and low residue pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

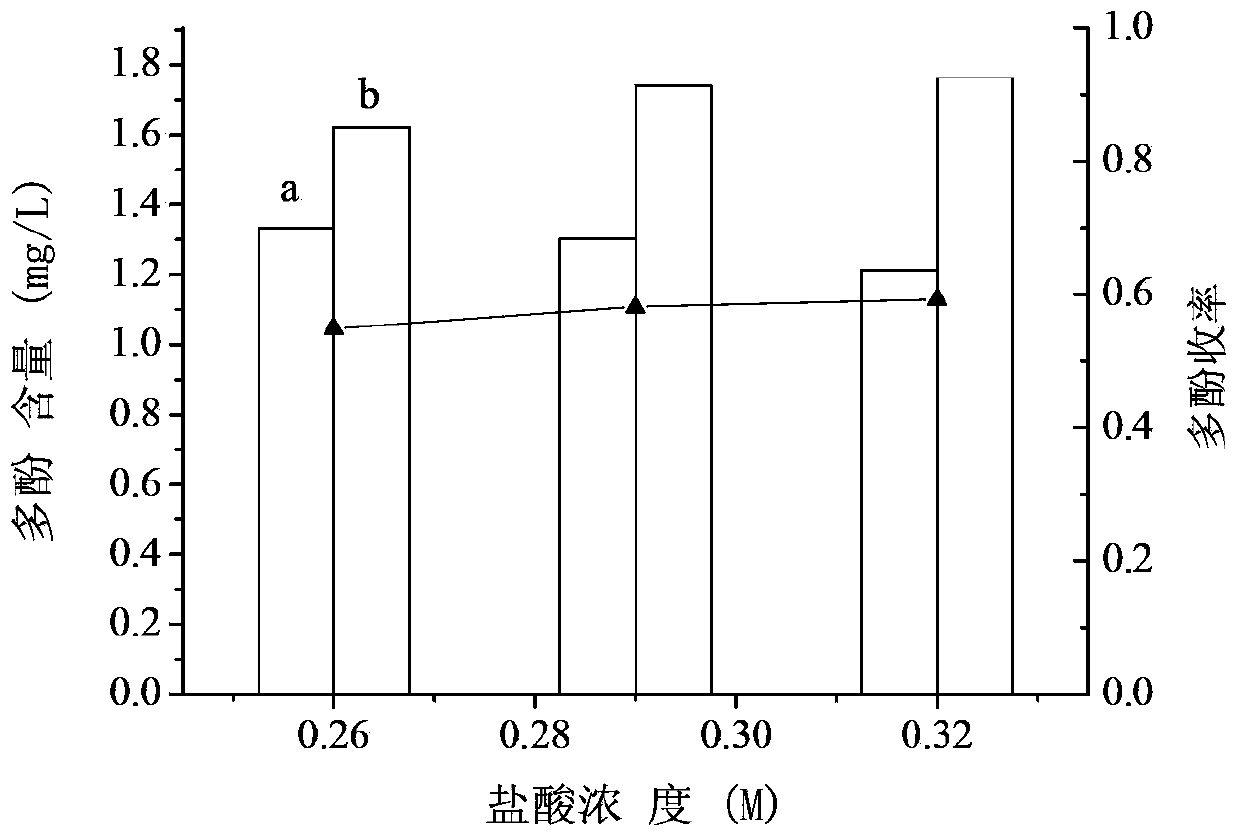

[0028] Drain the washed longan kernels, put them into a blast drying oven and dry them under different conditions, namely 40°C for 48h, 50°C for 23h, and 60°C for 20h. The longan kernels obtained by drying under different conditions were pulverized and poured into the extraction tank. With a solid-liquid ratio of 1:50, leaching solvent PB with a concentration of 10 mM at 70 ° C and a pH value of 7 was added, stirred with a stirrer, and extracted. Take 1.5h, pour out the leaching solution, filter under the condition of 0.06-0.08Mpa vacuum degree, remove the leaching residue, recover the leaching solution, measure the polyphenol content in the leaching solution by Folin’s phenol method, and compare the different drying conditions Process the leaching rate of the longan kernel powder that obtains, the result is as follows figure 1 shown.

Embodiment 4

[0030] Drain the washed longan kernels, put them into a blast drying oven and dry them at 50°C for 30h. Crush the obtained longan core and pour it into the extraction tank, add leaching solvent PB at 70°C, concentration 10mM, pH value 11 at a ratio of 1:40, stir with a stirrer, leaching for 25min, and leaching Take the liquid and pour it out, filter it under the condition of 0.06-0.08Mpa vacuum degree, remove the leaching residue, recover the leaching liquid, measure the polyphenol content in the leaching liquid by Folin’s phenol method, the leaching rate of longan kernel polyphenols is 46.86mg / g .

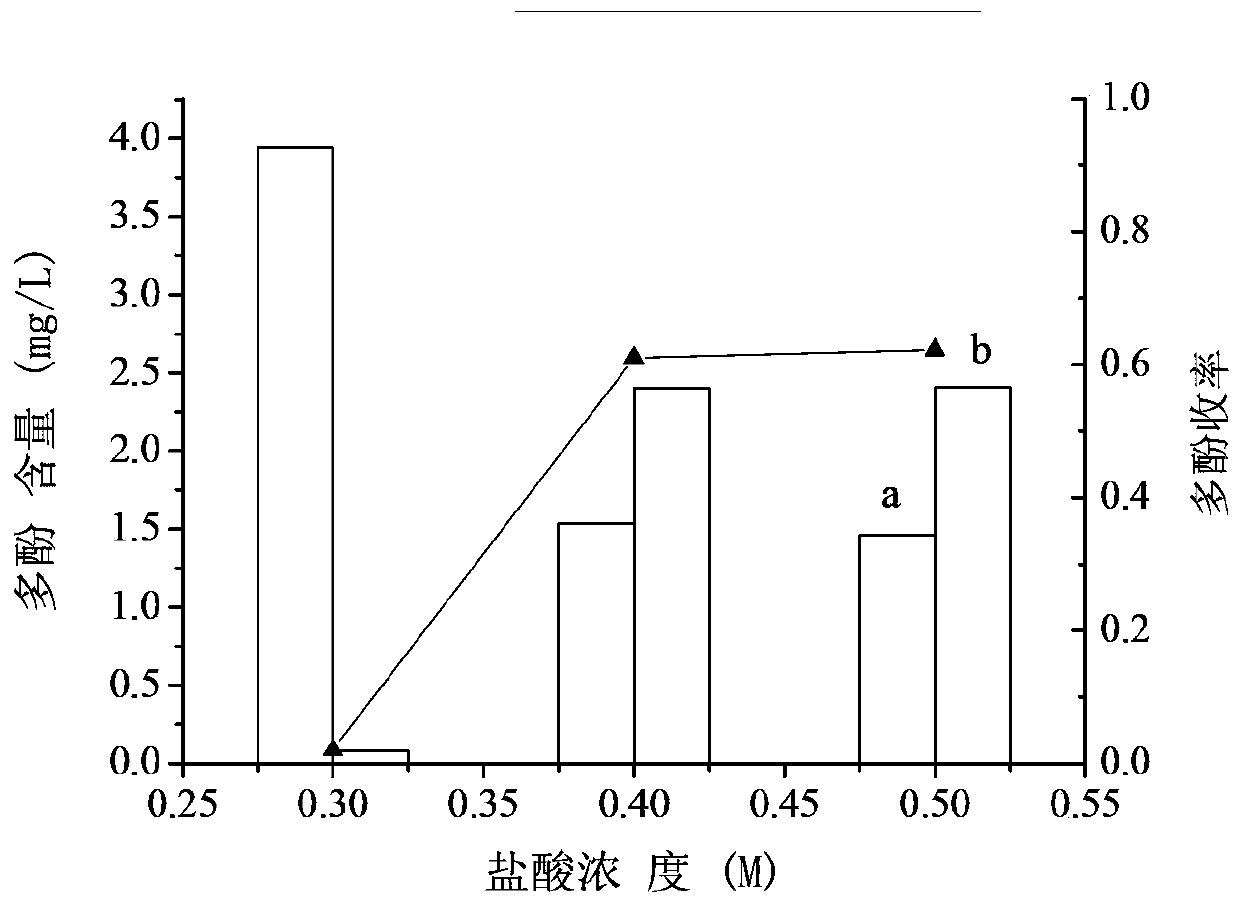

Embodiment 5~6

[0032] The leaching operation conditions as described in Example 4, the longan kernel polyphenols were leached with different pH sodium phosphate buffer solutions. The difference is that the pH of the sodium phosphate buffer is 9 and 10, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com