Zero resistance insulator detection method on basis of finite element database

A technology of zero-value insulators and detection methods, which is applied in the direction of electrical digital data processing, special data processing applications, and measurement of electricity, and can solve problems such as inaccurate judgment, aggravated threat of short-circuit faults, and large manpower consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

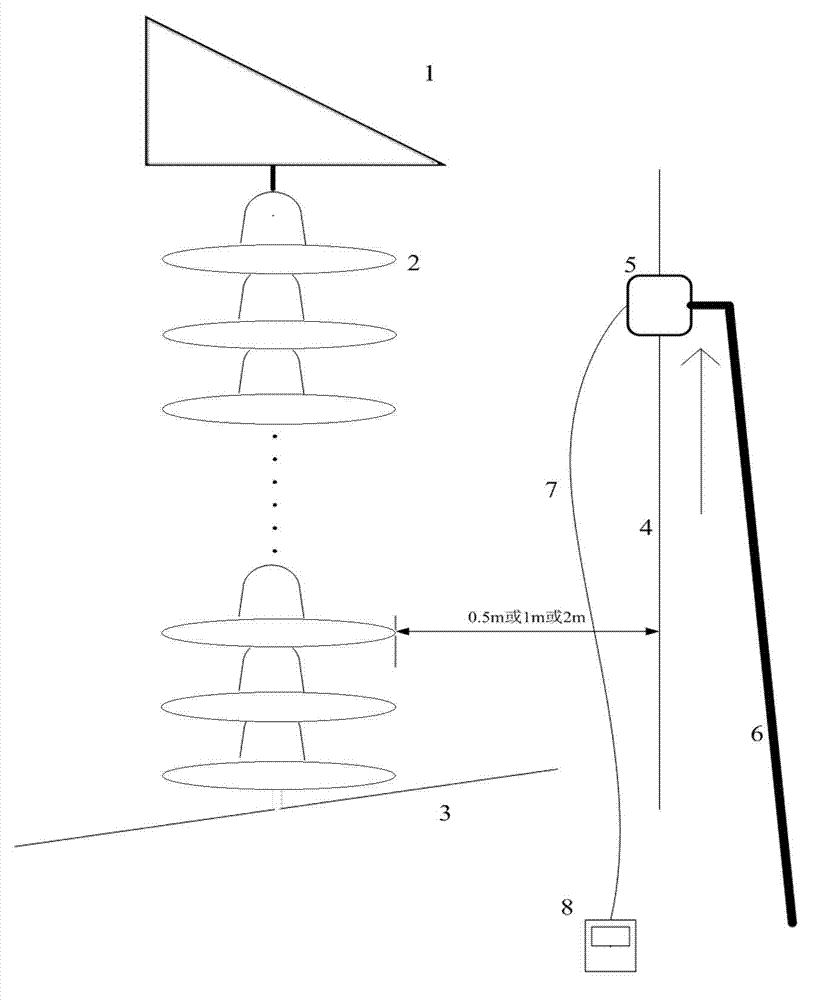

[0016] like figure 1 , a zero-value insulator detection method based on the finite element database, including the following steps:

[0017] (1) Use finite element analysis software to establish a model database of typical transmission line towers and corresponding insulator strings;

[0018] (2) Use finite element analysis software to analyze the electric field of the insulator string model in the model database: calculate the spatial axial electric field distribution of each model on the axial path at 0.5m, 1m, and 2m away from the insulator string, and obtain the insulator string The relationship curve between the axial coordinates and the space electric field value, and establish the space electric field distribution database of the insulator string;

[0019] (3) On-site detection of zero-value insulators: use the non-contact electric field test m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com