Fluid-solid coupling analysis based erosion destruction invalidation quantitative forecast method

A technology of fluid-solid coupling and prediction method, which is applied in the direction of analyzing materials, measuring devices, testing wear resistance, etc., and can solve problems such as the lack of theoretical basis and the inability to accurately predict the failure location and rate of fluid pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with examples of implementation.

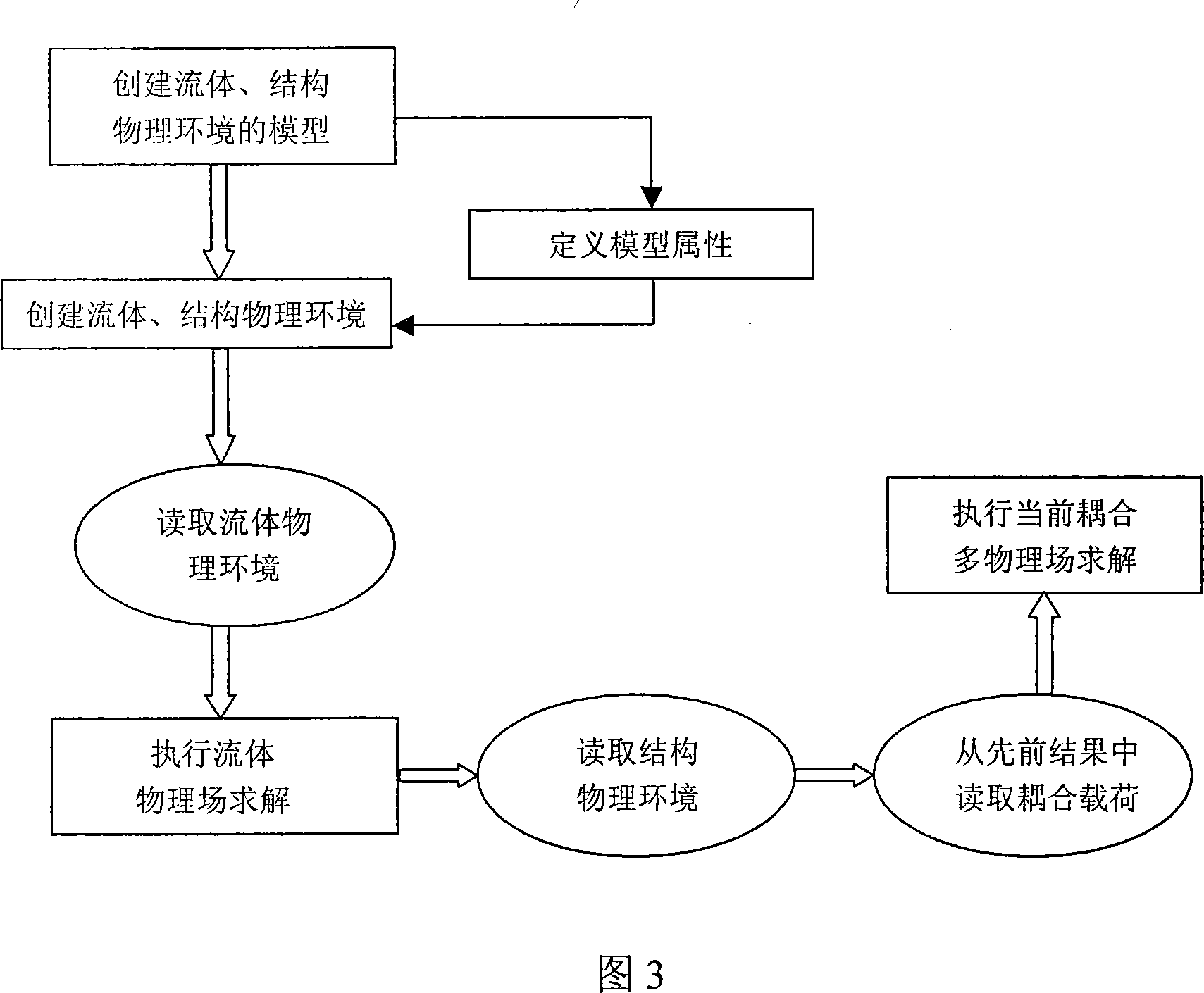

[0028] A quantitative prediction method of erosion damage failure based on fluid-solid coupling analysis of the present invention is applied to the quantitative prediction of erosion damage failure of the catalytic fractionation tower top return pipeline system, including analysis of corrosion product protective film characteristics and failure under fluid action Predictive analytics has two processes.

[0029] 1. Analysis process of corrosion product protective film characteristics:

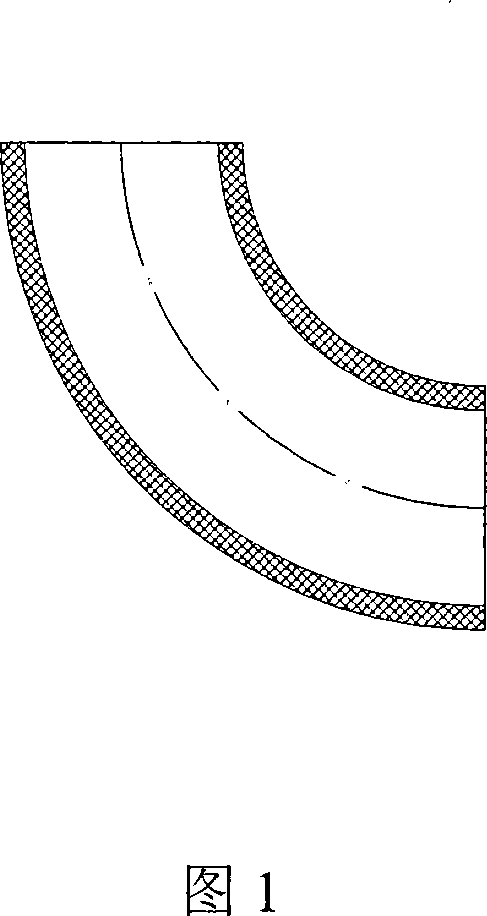

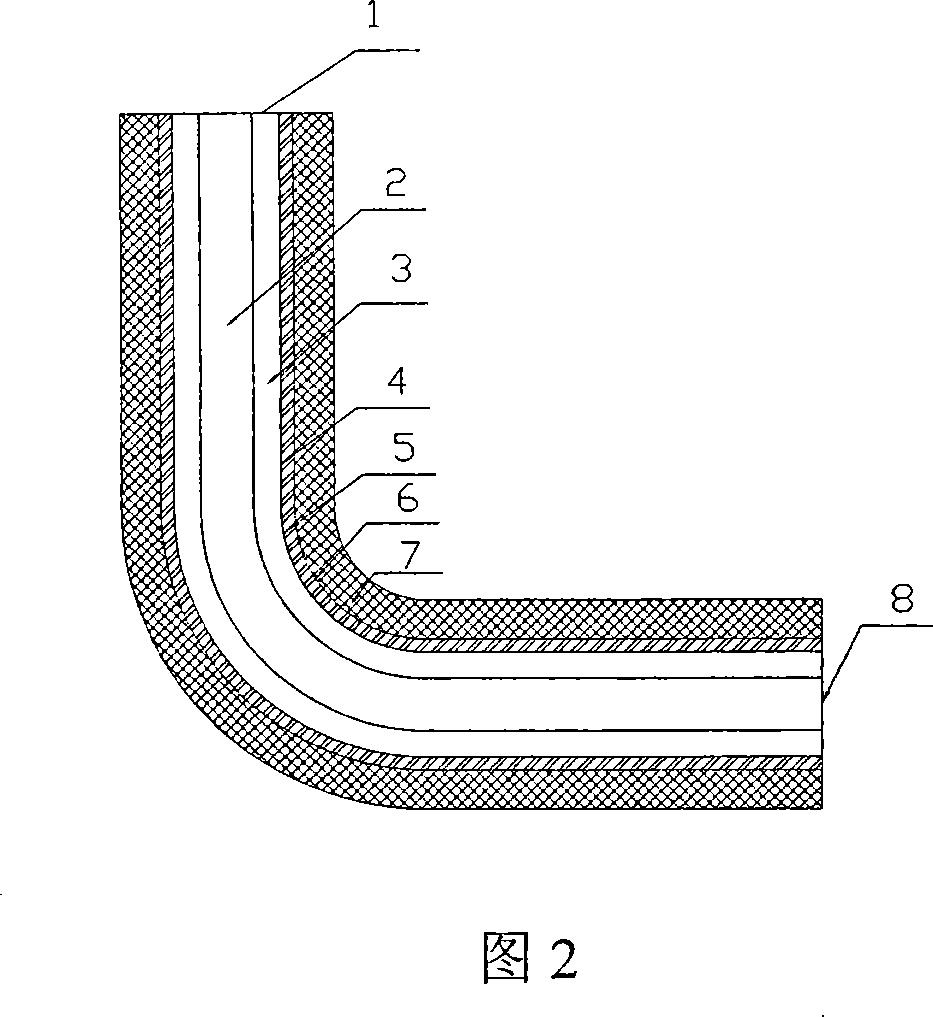

[0030] a. The structure of a typical pipe fitting in the top reflux piping system of the catalytic fractionation tower—the elbow pipe is shown in Figure 1. The specification is 325×8mm, the radius of curvature is 450mm (1.5Dg), and the corrosive fluid medium in the system is at a pressure of 0.15 There are three phases of oil, gas and water at Mpa and temperature of 30°C, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com