Sulfurized isobutylene closed path preparation industrialization method

A closed-circuit sulfurized isobutylene technology, which is applied in organic chemistry and other fields, can solve problems such as low profit, reduce production cost, and reduce reaction efficiency, and achieve the effects of improving environmental impact, reducing production cost, and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

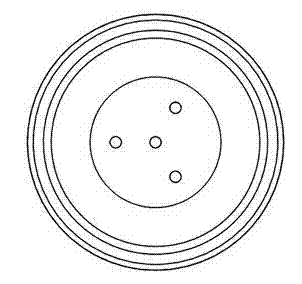

[0031] Such as figure 1A closed-circuit preparation industrial method of sulfurized isobutylene is shown, the method is carried out in a closed-circuit reaction system, and the closed-circuit reaction system includes a raw material replenishment unit, a three-phase separation unit, a waste liquid purification unit, and a hydrogen sulfide recovery system, Wherein the raw material replenishment unit comprises a sulfur monochloride transport tank 12, a sulfur monochloride storage tank 13, and an addition reactor body 1, and the sulfur monochloride transport tank 12 is communicated with the storage tank 5 by double pipelines, and the The sulfur monochloride storage tank 13 is communicated with the addition reactor body 1 by double pipelines; S 2 Cl 2 According to the principle of the connecting device, it flows from the transport tank 6 into the storage tank 5 through gravity flow, realizing the transportation in a pollution-free and airtight state.

[0032] Addition reactor bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com