Interference color glass bead and preparation method thereof

A technology of colored glass and glass microbeads, applied in the field of glass microbeads, can solve the problems of poor reflection effect of glass beads, reduce reflection effect, and less use of reflection fields, etc., so as to facilitate popularization and application, increase reflection performance, and good reflection performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

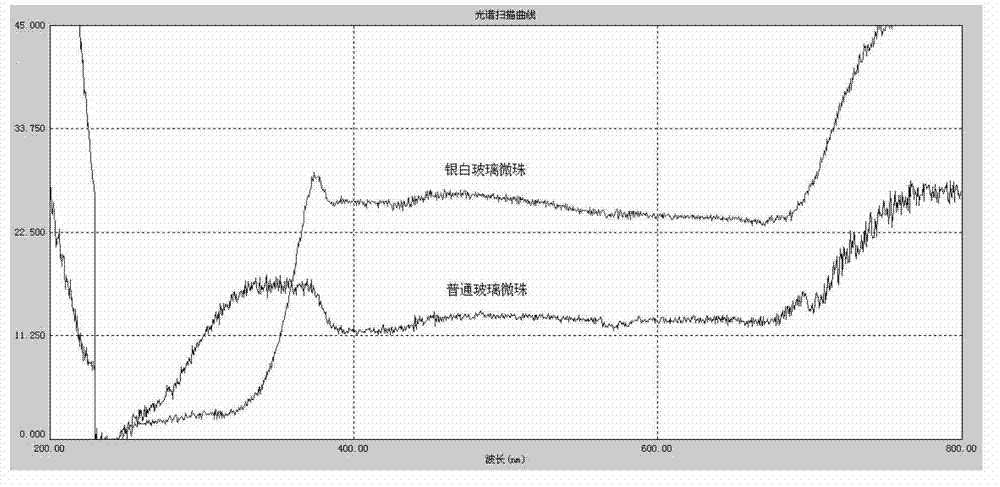

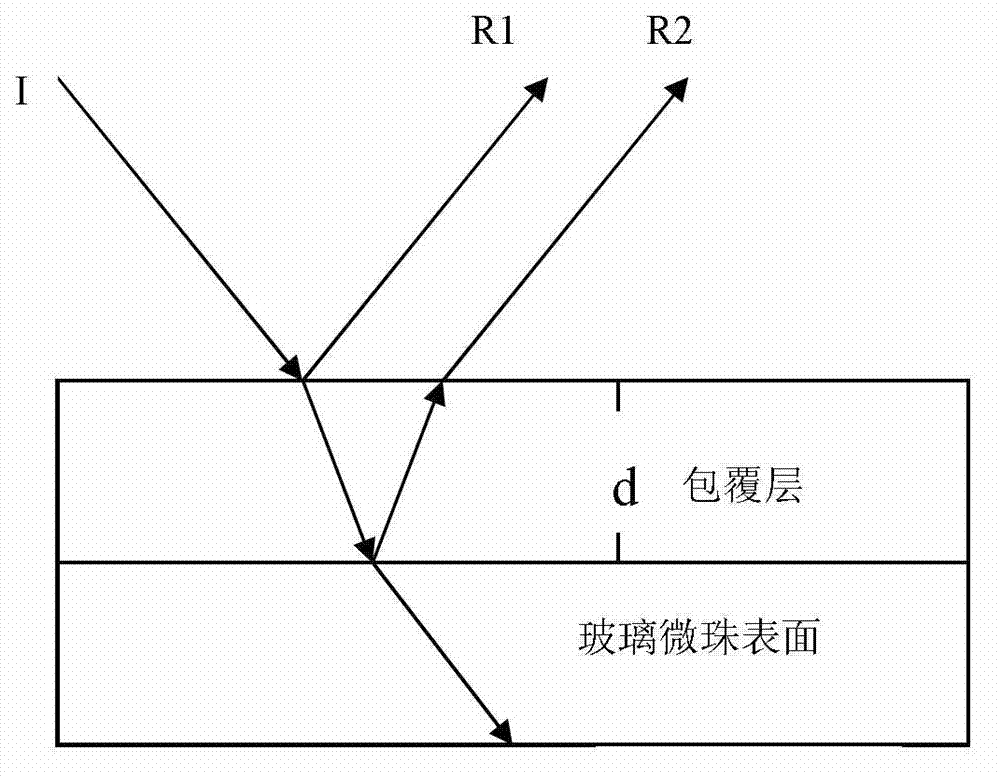

Embodiment 1

[0039] Weigh 10g of glass beads into a 250ml three-neck flask, add 200ml of deionized water, stir and wash with water for 10 minutes, let stand for a while, pour off the upper liquid, repeat the above steps twice, and wash with water. Then add 80ml of deionized water, adjust the pH value to 9 with NaOH, stir for 10 minutes, let stand for a while, pour off the upper liquid, and finish the alkali washing. Add 80ml of deionized water, adjust the pH value to 2.5 with hydrochloric acid, and stir for 10 minutes. Heat the solution to 60°C and add 100g / L of TiCl dropwise at a rate of 0.3ml / min 4 solution, while adding dropwise a 10% NaOH solution to adjust the pH of the system at 2.5, stop adding TiCl when the resulting product appears silvery white 4 solution and NaOH alkaline solution. The solid product was filtered out, washed with deionized water, dried at 150°C, then placed in a muffle furnace, heated to 650°C, calcined for 30 minutes, and naturally cooled in the furnace to obt...

Embodiment 2

[0043] Weigh 10g of glass beads into a 250ml three-neck flask, add 200ml of deionized water, stir and wash with water for 10 minutes, let stand for a while, pour off the upper liquid, repeat the above steps twice, and wash with water. Add 80ml of deionized water to the flask, adjust the pH value to 9 with NaOH, stir for 10 minutes, let stand for a while, pour off the upper liquid, and finish the alkali washing. Add 80ml of deionized water, adjust the pH value to 2.5 with hydrochloric acid and stir for 10 minutes. Heat the solution to 60°C and add 100g / L of TiCl dropwise at a rate of 0.3ml / min 4Solution, while adding dropwise a 10% NaOH solution by mass percentage to stabilize the pH of the system at 2.5, stop adding TiCl dropwise when the resulting product turns blue. 4 solution and NaOH alkaline solution. Filter out the solid product, wash it with deionized water, dry it at 150°C, put the dried colored glass beads into a muffle furnace, heat it to 650°C, bake it for 30 minu...

Embodiment 3

[0045] Weigh 10 g of glass microspheres into a 250 ml three-neck flask, add 200 ml of deionized water, and stir at 300 rpm. Stir and wash with water for 10 minutes, let stand for a while, pour off the upper liquid, repeat the above steps twice, and wash with water. Add 80ml of deionized water to the flask, adjust the pH value to 9 with NaOH, stir for 10 minutes, let stand for a while, pour off the upper liquid, and finish the alkali washing. Add 80 ml of deionized water, adjust the pH value to 2 with HCl and stir for 10 minutes. Heat the solution to 50°C and add 35g / L of SnCl dropwise at a rate of 0.2ml / min 4 Solution 20ml, while adding dropwise 10% NaOH solution to stabilize the pH of the system at 2. Stir for 10 minutes after the dropwise addition is complete. Add 10% NaOH solution dropwise to stabilize the system pH at 2.5, then add 100g / L of TiCl dropwise at a rate of 0.3ml / min 4 solution, stop adding TiCl dropwise when the resulting product turns red 4 solution and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com